Day: November 1, 2022

Rampal Coal-fired power plant – A Major Solution to Bangladesh’s Power Crisis

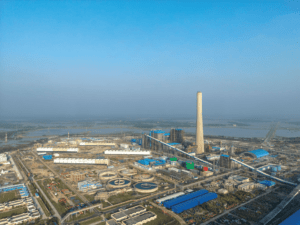

Bangladesh is at an unprecedented crossroads with power crisis and hyper inflation. At a time when major industries at home suffer an acute power crisis, aggravated by the the Russia-Ukraine war following the Covid-19 pandemic, the recent soft inauguration of the first unit of the 1,320-megawatt Maitree Super-Thermal Power Project, also known as Rampal Power Plant, is believed to have been a relief from the energy crisis. Amid the crisis globally, Bangladeshi stakeholders, especially those involved with the multi billion-dollar export industries, manufacturing sector and the financial sector, are now waiting wholeheartedly for commercial operation of the Rampal Power Plant soon to rid the nation of this power predicament. Domestic energy experts and analysts alongside other stakeholders look optimistic with this project and they are of the opinion that the Rampal power project is economically feasible, sustainable and profitable. Terming it one of the cheapest power plants of its kind in the country, they strongly viewed that the plant will get going with the key objective of generating affordable electricity as a resilient and viable solution to the country’s power crisis. Prime Minister Sheikh Hasina and her Indian counterpart Narendra Modi jointly inaugurated the first unit of the coal-fired super-thermal plant through video conferencing on September 6, 2022. The country’s largest power plant is sited on an area of more than 915 acres of land in Rampal upazilla in south-western Bagerhat district under Khulna division, some 272 kilometres away from the capital Dhaka. The high-efficiency, low-emission supercritical plant site sits 14 kilometres north of the world’s largest mangrove forest, the Sundarbans. About the funders The Rampal power project is a joint venture between India’s state-owned National Thermal Power Corporation (NTPC) Ltd and the state-owned Bangladesh Power Development Board (BPDB). The US$ 2.00 billion joint venture company is known as the Bangladesh-India Friendship Power Company Ltd. (BIFPCL) that builds, runs and operates this power facility. The BIFPCL has been co-promoted by the BPDB of Bangladesh and the NTPC Ltd of India with an equal (50:50) equity investment. According to Bangladesh’s power ministry, the joint venture company will enjoy a 15-year tax holiday. In March 2022, Bangladesh boasted the country’s access to 100 per cent electricity, but the national power grid system failed in July and power outage suddenly began to disturb the nation and the socio-economic activities. The Power Division disclosed that the largest amount of what is technically called load-shedding per day stood at 2,000–2,200 MW during the July-September period. But this shortfall peaked in October, taking it to 2,500–3,000 MW. The start of the project BPDB and NTPC entered into a memorandum of understanding (MoU) instrument in 2010 to implementing this mega power plant project in Bagerhat’s Rampal upazilla that has seen an upturn in economic activities centring this power plant in recent years. An estimated 80 per cent of the project costs will be covered through a long-term loan from the EXIM Bank of India. As the construction of the facility was ongoing, the February 2021 was set as the first deadline for commissioning the power plant’s first unit while the second unit by August 2021, according to competent sources. However, the deadline was extended several times for a number of reasons, including emergence of the Covid-19 pandemic in 2020. Use of coal and technology A coal-fired plant produces electricity by burning coal in a boiler to produce steam. Then the steam, produced under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then cooled, condensed back into water and returned to the boiler in order to start the process over. Supercritical combustion technology and sophisticated equipment are being used to lessen environmental hazards and thus make this project safe and eco-friendly. Some 6,500 cubic meters of water will be required per hour and minimum 10,000 tonnes of coal will be required to produce 1300 MW electricity every day. The ash content of this imported Indonesian coal is 8-10%. The height of chimney is 275 meters, equivalent to 90 storied building. In its initial stages, there was a strong debate on the red-hot issue of installing this coal-fuelled thermal power facility near a forest and some termed it suicidal with apprehensions of environmental disaster for the forest, which is home to thousands of wild species, flora and fauna. Some environmentalists made a mass call for scrapping of the project. The government, however, showed its determination to go ahead with the project. State energy experts said the project would not be harmful as its supercritical technology will minimise ecological hazards. Eco-warriors demanded that environmental concerns must be given precedence over commercial interest. They called for doing an environmental impact assessment and feasibility study before embarking on the project that may have anthropogenic impacts on environment, including effects on biophysical environments, biodiversity and other resources, let alone emissions of carbon dioxide and other pollutants as well as particulates. The joint venture company has already planted 116,000 different kinds of trees around the project site while the Centre for Environmental and Geographic Information Services (CEGIS) is monitoring the parameters related to the environment of the Rampal site and its adjacent areas, including Khulna and the Sundarbans. Employment opportunities The Rampal power plant project has opened up a job generation opportunity for local people and those affected for construction of this project’s infrastructure and during its operational period. As this region has long remained underdeveloped, opportunity of trade and employment was very limited. The power plant project has come as a relief to some extent. Alongside direct employment in the BIFPCL, there will be a huge opportunity to the locals for business and other indirect employment prospects. Moreover, this industry will usher in economic growth in Rampal in particular and the country in general, creating many downstream and/or related industries. Supply chain The supply chain of coal in all coal-fired power plants, including the Rampal power plant, is the biggest challenge. Technically unique in the plant is the supply chain issue. The Rampal

Read More