A Parcel That Changed Everything

In the early 1980s, a seemingly ordinary parcel delivered from Italy to a Bangladeshi family quietly set the stage for a life-changing transformation. Inside were handmade clay tiles—simple, earthy, and elegant—that inspired a new industrial journey rooted in tradition.

The arrival of the tiles sparked an unexpected curiosity, drawing the family, engaged in ship management, into the intricate world of terracotta craftsmanship. This newfound passion led them from coastal shipping operations to the rural “Pal Para” villages, where generations of potters lived and worked.

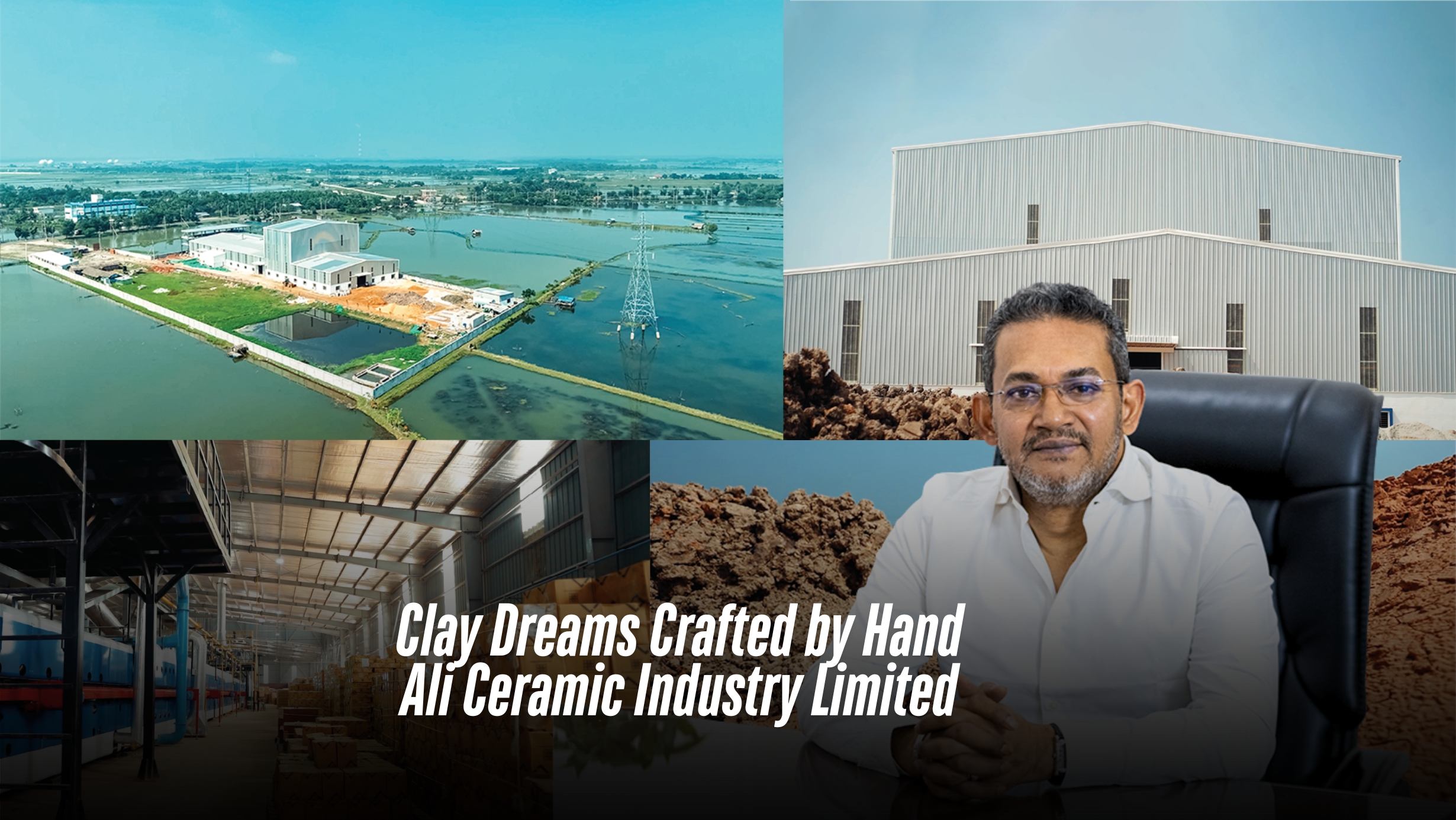

Decades later, that spark has evolved into Ali Ceramic Industry Ltd (ACIL), a rising name in Bangladesh’s ceramic sector. The company is now dedicated to producing 100% eco-friendly terracotta tiles, continuing a legacy built over 43 years. Backed by deep experience and a commitment to preserving clay artistry, ACIL is on a mission to blend sustainability with tradition.

However, the ceramic maker had to go through numerous hurdles to reach today’s position. From economic turmoil to energy challenges, Ali Ceramic’s journey has tested its resilience—making its commitment to green craftsmanship truly admirable.

From Shipping to Shaping Clay

Before entering the ceramic business in 1982, the family of Ali Askar—now the Managing Director of ACIL—was involved in managing ships. Askar himself was just a Grade 9 student when he first began assisting in the family’s factory office. What started as part-time help during his school years gradually grew into a lifelong calling.

The pivotal moment came through a surprising phone call. One day, Askar’s father was contacted by an Italian friend who asked if a product could be manufactured in Bangladesh. Without disclosing details, the friend sent a parcel. Inside were handmade clay tiles—a product so visually striking that it would eventually redefine the family’s business path.

In Search of the Perfect Artisan

Motivated by the parcel, Askar set out on a mission to find skilled artisans capable of replicating such craftsmanship. He travelled across Bangladesh, visiting various districts and exploring ‘Pal Para’—traditional villages of potters where pottery is not just a livelihood, but a way of life.

After surveying several regions, Askar discovered exceptional potters in Satkhira. The Italian friend even joined a visit to the village and was impressed by the quality of work. This validation paved the way for launching an export-oriented business producing 100% eco-friendly handmade terracotta tiles under the name Maa Cottos Inc.

Maa Cottos and Nikita International:

A Legacy in Clay

Maa Cottos Inc. serves as the parent company of ACIL, while Nikita International—another venture under the same umbrella—also manufactures 100% handmade terracotta tiles. Founded in 1982 as a family-run enterprise, Nikita International has grown into the largest handmade tile manufacturer not only in Bangladesh but across Southeast Asia.

Over the past four decades, the company has built a reputation for high-quality structural clay products, including roof tiles, wall cladding tiles, and floor tiles. Their dedicated in-house research and development team continues to innovate, ensuring they remain relevant in both domestic and international markets.

While Nikita International specialises in a broad range of traditional clay products, ACIL has taken a more modern approach, focusing on high-end machine-made terracotta tiles designed for contemporary architectural projects.

Ali Ceramic’s Battle to Rise

“Ali Ceramic was established in 2021, but its commercial production began in July 2024,” said Ali Askar.

With a current daily output of 40,000 square feet of tiles and 170 employees, the company has already made a strong start. Its total investment stands at Tk 1.5 billion. However, Askar noted that despite this solid foundation, ACIL’s growth is being hampered by external challenges such as political instability and economic uncertainty.

The July Uprising

One such challenge emerged shortly after ACIL began full-scale production. Within a year, Bangladesh was shaken by the July Uprising, which brought government development projects to a halt.

According to Askar, many of the contractors they had established relationships with were replaced in the wake of political upheaval, severing existing business ties. The re-tendering process for paused projects introduced further delays and added a new layer of unpredictability to ACIL’s business landscape.

Production Challenges: Energy and Raw Materials

In addition to political disruption, ACIL has faced ongoing operational difficulties. A key concern is the absence of a Titas gas connection, which has forced the company to rely on liquefied petroleum gas (LPG)—a costlier alternative that significantly raises production expenses.

Despite these setbacks, ACIL has managed to maintain product quality. Clay is sourced from regions such as Gazipur and Sylhet, chosen for their reliable natural composition and consistency, ensuring each tile meets the company’s exacting standards.

Handmade Tiles: Craft Holds the Crown

While machine-made terracotta tiles remain common among Bangladeshi producers such as Mirpur Ceramic Works Ltd. and Khadim Ceramics Ltd., there is a noticeable shift in the global market.

Foreign buyers are increasingly drawn to handmade tiles for their aesthetic charm and artisanal value. This growing demand reaffirmed Askar’s decision to launch ACIL as a complement to the handmade offerings already being exported by Maa Cottos Inc. and Nikita International.

Reaching 22 Global Destinations

Today, Askar proudly notes that handmade tiles produced under the group’s brands are exported to 22 countries—including Germany, France, Italy, Spain, and Japan. The appeal lies in the product’s eco-friendly, handcrafted nature, which resonates strongly with environmentally conscious consumers around the world.

Why Imported Tiles Still Dominate the Market

Despite this progress, the local ceramic industry continues to face stiff competition from imports. Around 20–25% of Bangladesh’s ceramic demand is still met by foreign tiles, mainly from China, Spain, Turkey, and Vietnam.

This dependence stems from Bangladesh lagging nearly five years behind in design and innovation. Although the country has no shortage of skilled ceramic professionals, much of this talent remains underutilized due to a lack of investment in advanced machinery and modern design capabilities.

Until the industry catches up in both creativity and technology, imported tiles will likely continue to dominate the high-end segment of the market.

A Call for Government Support

Currently, ACIL generates annual sales worth around Tk 210 million (over USD 1.75 million). The company has set its sights on reaching Tk 500 million (over USD 4 million) in the near future.

To support this growth, Askar called on the government to provide subsidies for new ceramic ventures and extend utility support that could ease the financial burden on emerging manufacturers.

“We’re committed to producing green, sustainable products,” he said. “But we need the government’s help to overcome energy challenges and market instability.”