An integral part of Dhaka’s image in terms of historical architecture that still remains and has been renovated and preserved is the Ahsan Manzil. And like many of common folks who grew up in Dhaka, they have always wondered, at least once in their lives, the reasons behind why this iconic landmark is painted pink. Perhaps unsurprisingly, Ahsan Manzil’s history is even more colourful. This iconic building was built on a property that has a rich history dating back to the Mughal era at the southern part of Dhaka. During the Mughal Empire, Sheikh Enayet Ullah, Zamindar of the Jalalpur Porgona (Faridpur-Barishal), who was the original owner of the land, built a palace called Rong Mahal (which loosely translates as ‘Colourful Palace’) in 1720 for his amusement, a typical practice amongst wealthy elites at the time. He also had a garden house and a cemetery on this site. After he passed away, his son Sheikh Moti Ullah sold the property to the French traders in Bengal at the time. The new owners soon established a trading house next to the palace. Later, after being defeated in the Palashy War by the British East India Company in 1757, they had to leave their possessions behind. After changing hands a number of times, the property was purchased by Khwaja Alimullah of Begambazar in 1830, who was a prominent merchant and an important figure of Dhaka’s Muslim community at the time. Alimullah renovated the property, turning the trading house into a residence. He also built a mosque and some other important structures in this area. After his death in 1854, his son Khwaja Abdul Ghani inherited the property and named it Ahsan Manzil after his son Khwaja Ahsanullah. He continued renovations; the old building was renamed Ondor Mohol (ladies quarters) and the new building was called Rangmahal (pleasure palace) and was later renamed Ahsan Manzil. Khwaja Abdul Ghani was one of the most influential Nawabs (Zamindar) of Dhaka. Known for his generosity and patronage of arts and culture, he expanded his estate by acquiring more lands around Ahsan Manzil and also played an important role in improving the infrastructure, education, healthcare, trade, and social welfare of Dhaka. In 1859, he built a new building on Ahsan Manzil’s property that resembled European architecture because of its domes and pillars. The Nawab named it Rangmahal and painted it with different colours every year according to his mood. On 7 April 1888, Ahsan Manzil suffered severe damage from a tornado that impacted most of its buildings, except for Rangmahal and it was temporarily abandoned. Khwaja Abdul Ghani then decided to rebuild Ahsan Manzil with more vigour and decorations than previous ones. He hired Martin & Co., a British construction and engineering f irm, who designed Ahsan Manzil with an Indo-Saracenic style, blended with Islamic and European elements. In 1872, the reconstruction work continued under Khwaja Abdul Ghani’s supervision, what was previously the French trading house was rebuilt as a two-storey building similar to the Rangmahal. A wooden bridge connected the first floors of the two buildings. After he died in 1896 at the age of 87 years, his son Khwaja Ahsanullah continued his father’s legacy by taking care of the palace. He added new features like electric lights, gas lamps, and water pumps as part of modernization. The palace was repaired again following the 1897 Assam earthquake. The Nawab family played crucial roles in the modernisation of the Dhaka city, particularly in the development of educational systems, healthcare, and urban infrastructure, including the f iltered water supply system that served the city population. They occupied important positions as Commissioner of Dhaka Municipality. Today, within the hyper-congested and cacophonous urban growth of Old Dhaka, it is difficult to imagine how this majestic edifice once dominated the riverfront skyline of Dhaka. The landmark is a unique fusion of architectural styles, reflecting the rich cultural influences that shaped Bengal it over the centuries. The main palace building showcases a harmonious blend of Mughal and European architectural styles. The Mughal influence is evident in the structure’s domes, arches, and intricate decorative motifs. The ornate design of the palace’s entrance and interior chambers reflects the opulence that was characteristic of the Mughal era. European influences, on the other hand, are seen in the high ceilings, broad staircases, and expansive verandas. The palace’s central ballroom, adorned with crystal chandeliers and European-style furniture and tableware, exudes an air of sophistication that was imported from Europe during the late 19th century. The building faces the Buriganga River and Buckland Dam. On the riverside is a stairway leading up to the 1st floor. A fountain previously sat at the foot of the stairs but was not rebuilt. Along the north and south sides of the building are verandas with open terraces. Ahsan Manzil is ostentatiously European in its architectural expression, even though the building’s recessed verandahs may recall the Mughal treatment of buildings in a tropical climate. Its triple-arched portal, Greco-Roman column capitals, pilasters, and arched windows—all suggest that it is mostly a European-style building, meshed with some decorative Indian motifs. The palace’s soaring dome appears to be more about impressing the viewer on the exterior, rather than within the interior. The dome is at the centre of the palace and is complex in its design. The room at its base is square with brickwork placed around the corners to make it circular. Squinches were added to the roof corners to give the room an octagonal shape and slant gradually to give the dome the appearance of a lotus bud. The dome’s peak is 27.13 metres (89.0 ft) tall. The palace is divided into the eastern side, the Rangmahal, and the western side, the Andarmahal. The Rangmahal features the dome, a drawing room, a card room, a library, a state room, and two guest rooms. The Andarmahal has a ballroom, a storeroom, an assembly room, a chest room, a dining hall, a music room, and a few residential rooms. Both the drawing room and

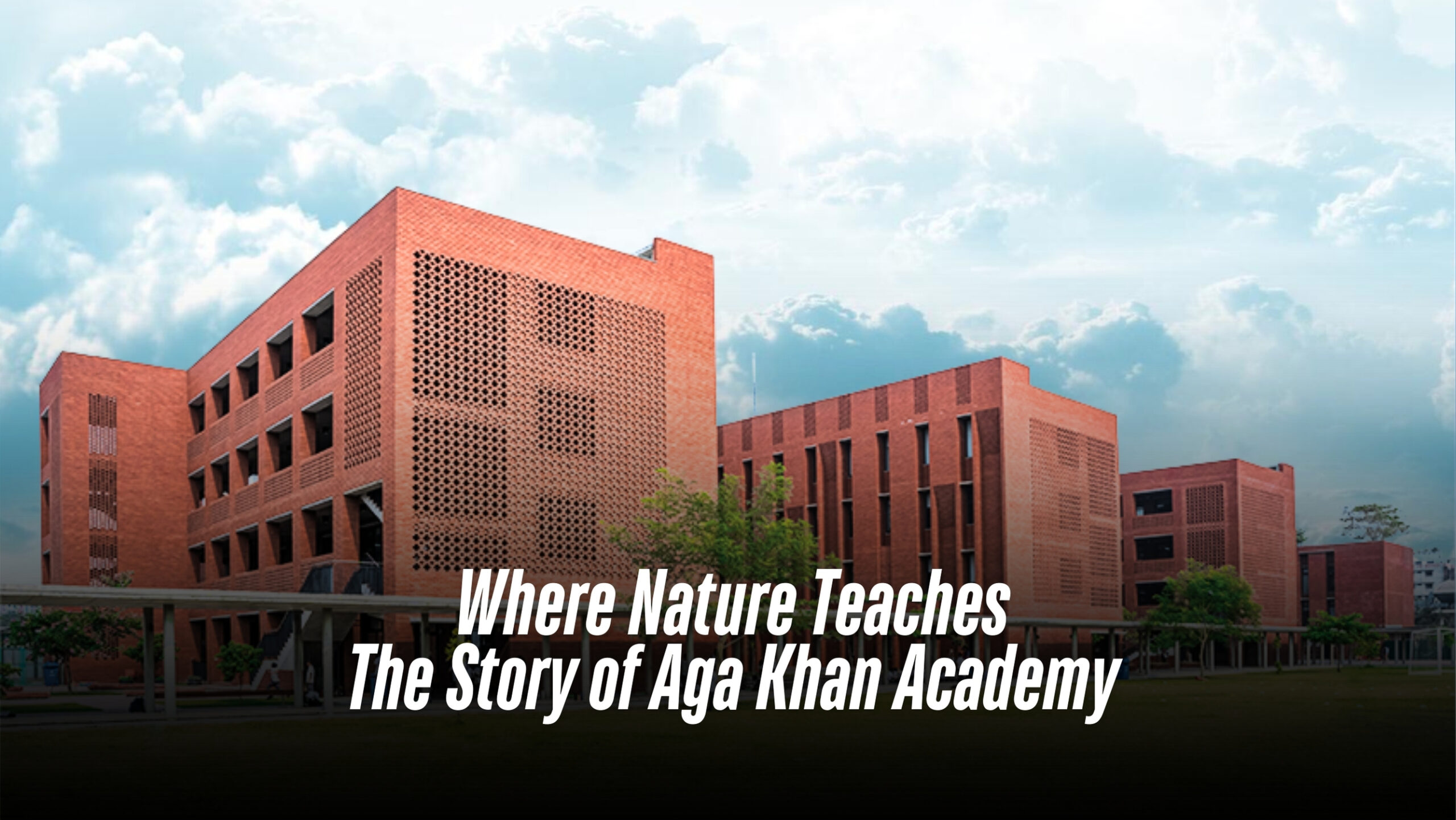

In Dhaka’s Bashundhara Residential Area, the Aga Khan Academy immediately catches your eye. Its warm brick walls, softened by greenery and a sparkling water channel, glow in the morning light. The building feels like a historical monument—orderly courtyards, intricate brickwork—yet the lively chatter of students reminds you this is a school—a place where learning blends seamlessly with nature’s rhythms. Bangladesh’s heritage that make it truly remarkable. Here, architecture becomes a canvas, interiors breathe with narrative, and every art installation stands as a tribute to the nation’s soul. Spanning in 17 acres, the award-winning Aga Khan Academy in Dhaka was developed through a collaboration between SHATOTTO Architecture for Green Living and Feilden Clegg Bradley Studios. The design draws inspiration from the region’s ancient Buddhist Mahaviharas, incorporating their architecture and philosophy into the campus. A clay model was used to visualise the design, helping stakeholders understand the campus’s spatial organisation before construction. Covering 74,150 square metres, this is Shatotto’s largest school project to date. The campus provides a green sanctuary within Dhaka’s urban environment. This academy represents a significant investment by the Aga Khan Development Network in Bangladesh’s future. As the fourth institution in a planned network of 18 Aga Khan Academies across Africa, South and Central Asia, and the Middle East, the Dhaka campus connects students to a wider academic and cultural community. Other campuses are located in Mombasa, Hyderabad, and Maputo, forming a global network focused on pluralism, leadership, and excellence. To support education from nursery to diploma level, Aga Khan Education Services required a permanent campus. This presented a challenge in a dense city like Dhaka. The project is designed to be scalable and sustainable, planned in seven construction phases. Since its first phase launched in September 2022, the academy has offered an integrated environment that connects nature with education, providing a calm setting within Bashundhara’s urban area. The Dhaka campus currently enrolls 750 students, with plans for expansion to 1,200. The masterplan includes residential facilities designed to accommodate students and staff from across Bangladesh and other countries. This lays the foundation for a diverse and inclusive learning environment upon full implementation. The vision for this project was led by Architect Rafiq Azam of Shatotto Architecture for Green Living, who incorporated Bangladesh’s heritage into the design. He conceptualized it as an “archaeological site, like our ancient monasteries.” Co-lead Architect Peter Clegg of Feilden Clegg Bradley Studios contributed global standards and technical precision. A central amphitheatre serves as a space for performances and gatherings. The adjacent Maidan, a large open playground, accommodates student activities, serving recreational and social functions. Brick buildings surround these shared areas on a planted base, offering unobstructed views of the Maidan from all directions. The Maidan functions as the campus’s central point, reflecting the spirit of ancient Buddhist Mahaviharas. These elements collectively support an environment where the physical space contributes to the educational process. “The school itself teaches,” says Rafiq Azam, lead architect of the Aga Khan Academy. “Students learn from books inside the classroom, but when they step outside, they begin to notice surroundings on their own — how water flows, how flowers bloom, how the sun moves across the sky, and how the breeze blows from a certain direction.” He adds, “This kind of learning happens naturally, guided by the environment rather than just by the teacher. The process encourages students to learn independently, beyond what is taught in the classroom.” Rafiq Azam emphasised the local context influencing the design, noting the significance of greenery, water, and rain in Bangladesh’s fertile landscape. This sensitivity is integrated into the campus layout, where natural elements are part of daily student life. The academy’s design heavily features brick, chosen for both its practical and aesthetic qualities, consistent with Bangladesh’s architectural history. Each brick is carefully positioned. According to Feilden Clegg Bradley Studios, brick was selected to revive local craftsmanship and to contrast with the render and concrete common in surrounding new buildings. The construction method involves deeply embedded mortar between brick pairs, a technique seen in historical sites, ensuring longevity and a timeless appearance. This strategic use of locally sourced brick, combined with Bangladeshi brick patterning, creates a cohesive campus. It establishes a hierarchy of spaces through its brickwork. Facade perforations allow daylight into interior corridors, using traditional techniques. Recessed windows, screens, and protruding brick columns provide shading for classrooms and create covered balconies and walkways. Classrooms are oriented to minimise solar gain in summer, with external walkways and adjacent buildings providing passive solar shading from the morning sun throughout the year. This ensures adequate daylight and outdoor views. Architects designed these spaces for passive heating and shading year-round to minimise energy consumption. This climate responsiveness was achieved through extensive sun pattern analysis and wind flow direction studies, optimising light and ventilation. The academy’s character reflects many original Buddhist universities in Bangladesh. It is defined by the massing and materiality of brick buildings located on a sculpted and planted landscape base surrounding the central Maidan. Alongside the main field, the complex includes smaller connected areas featuring concrete canopies for shelter, along with brick benches and planters. These peripheral spaces serve as transitions between the central Maidan and more intimate interior areas. Spaces are tailored for different age groups; for example, the senior courtyard offers shaded zones under planted trees for focused group activities. The assembly court is simple, with four ‘Dhaak trees,’ which inspired Dhaka’s name. The primary central courtyard accommodates larger gatherings and includes an amphitheatre built around a sand pit. This pit is designed to collect rainwater during heavy rainfall, holding up to 170 mm of water for approximately 10 to 30 minutes. The campus masterplan organises spaces into four zones—Intellectual, Moral, Physical, and Spiritual—supporting a holistic educational philosophy. Each block is designed for a specific function. The Academic Block, a central hub, contains administrative workstations, learning centers, group study areas, and a lecture hall, along with a terrace. Its white-walled classrooms vary in

Time is NOW for eco-friendly clay-made roofing tiles and now is TIME for tile makers. They are the Bangladeshi makers of clay tiles who have gone global as their tiles have opened up the door of a huge export possibility, especially to Europe. The making of clay tiles is simple but it needs amazing artistry as well as artisanal skills. Fluffy mud is made by mixing soil and water. It then dries in the sun and is burned only to turn into clay gold. The artistic tiles with Bengal clay have revolutionised the style. However, clay artisans were once about to lose their hopes and dreams with their centuries of tradition. They then have turned the corner and things are looking up with the coming of the modern machine-driven industry. The clay artisans have turned around to weave a new web of hopes and dreams. Famed for its ‘Tiles Empire’ over the years, Satkhira has eco-friendly roofing tiles to its credit. Kolaroa Bazar in Kolaroa upazila, some 18 kilometres of district headquarters, is one of the prosperous trading points in Satkhira. Murarikathi village is located just 1.0 km away from the upazila headquarters along the border of the district. The artisans of Murarikati-Sripatipur have built an empire of various sorts of roofing tiles. The village, also called Kumarpara, has now got the moniker ‘Italy Town’ plausibly for exporting a massive volume of tiles to the European country. Tile factories used to produce 700-800 containers a year just a few years back. Some 300-400 container tiles were exported to Italy through Mongla seaport. The price of the product per container is average US$ 15000 Eco-friendly tiles Eco-friendly tiles There is a huge local market for roofing tiles if these hand-made tiles are given a more modern touch and the initiative is taken to use them as an artisanal tile in buildings and structures. During the British raj, cottages, offices or residences of the gentlemen used to have tiles at the peak that are still visible in the ancient architecture of Britain. Although a large number of potters have left Bangladesh, some in Kolaroa have kept the traditional tile industry alive in the frontier district. Until the mid-1960s, there were hardly any houses in the country that did not have a tile-made house or two. As it came cheap, roofing tiles became popular after rice and wheat straw-built structures. The structures were felt cool and comfortable during the summer. How Palparaenters European market The traditional tiles industry almost sank into atrophy when the potters associated with tile production left the country in the mid-60s. Satish Chandra Pal, a native of Palpara in Kolaroa, started crafting house canopy tiles in about 1952. From there, potters spread across the country. As Mr Satish Chandra died after independence, the pottery business simply collapsed. Due to their deep-rooted poverty, many artisans left their ancestral profession. With the passage of time, the potters have changed. They are now making tiles using clay. In 2003, local potters created a revolution by pouring clay into a wooden frame and drying it in the sun, making Bengali tiles in line with Italian design. Since then, Bengali tiles are being exported to Italy How are the legacy-bearers? Among those artisans is Gostho Chandra Paul, the president of Kolaroa Upazila Tali Malik Samity [Tiles Owners Association] and also proprietor of Kolaroa Clay Tiles. But he now struggles to survive as his long-cherished art is on the verge of extinction for a number of reasons. The 60-year-old Paul, who has a three-member family, is producing 1,000 units of tiles at his factory per diem. Each unit is currently being sold at Tk 8.0. He earns Tk 1.6-1.7 million per annum. Getting disgruntled and disappointed over the waning business situation, most owners and workers associated with this industry have already lost their jobs. Mr Paul observed that modernity has affected almost all sectors of the country. However, the tiles industry is yet to get the touch of modernity. Production costs have increased manifold, but the price of tiles has not increased. Mr Paul’s forefathers launched crafting eco-friendly roofing tiles in 1947. However, it all started for Mr Paul in 1986 when he set himself up in business with Tk 3,000 only. Ten workers were employed at his factory when he started crafting eco-friendly roofing tiles traditionally. His uncle told him to be self-reliant and build his own future through the long traditional business, which he acquired lineally. But at least 40 tile factories got shut down in the past six years due to their persistent business losses. Now, the number of factories there is about 12. Almost 6,000 workers become unemployed and only 600 are absorbed elsewhere. For generations, the Pal community in the locality has been contributing a lot to this thriving sector. Mr Paul is also committed to continuing their forefathers’ business at any. In 2003, this clay tile was first exported to Italy. Businessman Ruhul Amin exported the eco-friendly tiles there. Arno Export Import, Shuvo Trade Limited, FH Khan Limited, Maa Cottos Inc., Nikita International, Koto Innovator, JK International, Polo Epo Organic Tiles and D Chandra Paul have followed Mr Amin’s footsteps. They are exporting tiles to Italy, Dubai, France, the UK, Australia, Germany and the Netherlands. Mr Chandra Paul, proprietor of Kolaroa Clay Tiles, said Mr Amin continued to look for suitable soil in different parts of the country for exporting tiles to Italy. Finally, Mr Amin found his desired soil in Murarikati area. He is the pioneer in exportable tile business. As the number of roofing tile factories increased in Kolaroa until 2019, the stock remained high at the time. Every year, 300-400 containers of tiles went to Italy. Such tiles are manufactured and sold for 6-7 months in a year. Usually, tile-making season starts from October and continues until the May-June period. Tiles cannot be crafted during the rainy season. Foreigners are using the tiles for floors and walls of their houses because of its eco-friendly nature.