Latest Issue

Of trinkets, chandeliers and everything be dazzling

Your home decor is an extension of your personality and style. It’s a reflection of your tastes, preferences, and values. Believing in the notion, Satori started its journey in 2012, to provide city dwellers with start-of-the-art home decor items. Conceptualized and founded by Shaon Tanvir, Satori is a pioneering brand in the world of high-end home decor items. All of its products are handpicked and imported from Dubai, Thailand & China based on customers’ demand. Currently, they have three branches in the city, two in Banani and the other one in Gulshan. Stepping into any Satori showroom, anyone is immediately enveloped in an aura of opulence. Majestic chandeliers, installed in intervals, illuminate the space, guiding your path, while framed mirrors capture and reflect your presence, enhancing a sense of warm welcome. Everywhere you look, there are countless trinkets and treasures. Feels like you have entered into the celebration of art, aesthetics, and all things visually captivating. “As pioneers in the industry, we specialise in importing and curating modern luxury home décor items that stand as a testament to our commitment to quality and style. More than a selling platform Besides selling retail home decor items, Satori provides complete home décor solutions according to individual clients’ needs or architectural design They also offer complete lighting solutions for residences, developers,’ corporates, resorts, boutique hotels, and more. “We specialise in providing customised lighting and total lighting solutions and often collaborate with architects and interior designers,” added Shaon Tanvir. The brand offers a wide array of unique design products, starting from miniature sculptures to grand chandeliers. One of its focused categories is lighting like table & floor lamps, wall lights, chandeliers, ceiling lights, track, spot and LED lights, ambiance lights, etc. Fast-moving gifts and small décor items like candle stands, showpieces, flowers, vases, cushion covers, runners, mirrors, metal wall art, and paintings are also some of the most sought-after items by the brand. Additionally, you will also find carefully selected signature small furniture like consoles, coffee and side tables, and other feature pieces at Satori. Adapting to Dynamic Trends As urbanisation and contemporary living redefine our lifestyles, Satori stands at the forefront, attuned to the evolving demands of its clientele. According to Shaon Tanvir, Satori has been playing a pivotal role in reshaping customer perceptions regarding home decor, transforming once-deemed luxuries into modern-day essentials. “What was once considered a luxury is now deemed a necessity,” she remarked, highlighting the brand’s role in reflecting and accommodating shifting consumer needs. Tanvir also emphasises the profound impact of travel and social media on consumer preferences. With increased exposure to diverse lifestyles and design aesthetics, customers now seek to replicate the lavish home decor they encounter online, demanding accessibility to such lifestyle elements within their own homes. Satori takes pride in popularising numerous unconventional decor items, introducing novel concepts to the local market. What distinguishes Satori and maintains its stronghold in the competitive home decor segment is its product offerings in the dynamic market landscape. The brand’s success lies in its ability to curate a selection of unique and trendy items, renowned for their aesthetic appeal. Satori not only introduces fresh decor concepts to the local market but also sources distinctive designs of established items, offering exceptional value to its customers. If you are looking for interesting items to bring added dynamics to your space, or simply looking for an ideal gift for someone’s housewarming party, Satori certainly deserves your attention.

Read More

TANGUAR BLUES

If you have ever had the blessing to travel extensively in Bangladesh, there is something in particular about her geography that you must have noticed: the plethora of her beautiful waters. Being the largest delta on earth, perhaps it is unsurprising that Bangladesh has her own unmatched collection of breathtaking, fericious, and soothing wetlands, rivers, and other different types of water bodies, and of course the mighty Bay of Bengal, where every drop meets. A notable part of Bangladesh’s water bodies are wetland ecosystems in the north-eastern part of Bangladesh, which are physically a bowl or saucer-shaped shallow depression, locally called a “haor”, which is basically known as a backswamp. During monsoons, haors receive surface runoff water from rivers and canals to become vast stretches of enchanting, turbulent waters. Over the course of the past few years, Tanguar Haor, located in Dharmapasha in Tahirpur upazila, Sunamganj district of greater Sylhet region, and the foothills of India’s Meghalaya, have cemented their place as a sensation amongst the minds of all types of tourists and travelers. Especially with the rise of travel vlogs and other types of travel-related videos in this time of social media and influencer culture, the popularity of spaces like Tanguar Haor skyrocketed. Even in off seasons, tourists and travelers of all types flock to Tanguar Haor to immerse themselves in it or to simply witness its allure. But what makes Tanguar Haor so addictive is the essence of its inexplicable aura of spirituality. Shutting your eyelids and just listening to the sounds of Tanguar Haor’s bluest of waters will engulf you and take you to a serene wonderland that is impossible to encapsulate with words. Spaces like Tanguar Haor always have their own stack of mythical tales and different kinds of histories. One such thing that goes hand in hand is music. The original stories of local music genres and the backdrops of many legendary creations are closely related to water. One such is a type of folk music called “Ghetu Gaan”, which originated from such types of wetland areas where parts of the year were dry and everyone was busy working in the fields, taking care of livestock etc. and had nothing much to do during the entire monsoon, is when the inhabitants, especially the boatmen and local poets and musicians, organically started crafting such music. Another very interesting fact about this art practice is that teenage boys were dressed up as girls to perform and dance in Ghetu Gaan. In fact, the plot of the last ever movie made by the legendary Bangladeshi novelist and filmmaker Humayun Ahmed, “Ghetuputro Komola,” revolves around the practice of Ghetu Gaan. The practice itself has a lot of very interesting and tragic histories. Although this particular practice is almost extinct now, other kinds of music are still an integral part of our lives. Tanguar Haor is also one of the largest natural water reservoirs in South Asia. This natural wonder is the second largest freshwater wetland in Bangladesh spread over an area of about 126 square kilometres, and is a reservoir of trees, fish, birds and natural biodiversity. More than 30 fountains from the world’s rainiest Meghalaya hills merge in this haor. The Tanguar Haor is called the mother of all haors and the mother of fisheries as well, with a catchment area of 12,665 hectares (31,275 acres) of land. Tanguar Haor is the largest wetland consisting of 51 haors in 18 mauzas of two upazilas (sub-districts) in Sunamganj. 30 square kilometers of water-logged main haor and the rest is residential and agricultural land. There are 88 villages in and on the banks of the Haor area. When the water dries up in the winter season, the banks (‘kanda’ in local language) of about 24 beels wake up, only the inner part of the kanda (banks) has the original beel, and the local farmers cultivate winter crops and boro paddy in the dry part. During this time the area was also used as a pasture. Migratory birds take shelter in the high banks (kanda) of Haor, submerged in water during monsoons. The haor is also known in Bangla as “Naikuri Kanda’s Chaikuri Beel” to the local people. IUCN is working to protect the biodiversity of this region. Tanguar Haor’s landscape is characterised by its seasonal flooding and drying cycles, creating a dynamic and ever-changing environment. During the monsoon season, the haor swells as it receives water from the surrounding hills and rivers, covering the land in a shimmering expanse of water. In contrast, the dry season reveals a mosaic of shallow lakes, marshes, and lush green fields, exposing the intricate network of channels and water bodies that define the region’s unique ecosystem. This cyclical transformation is a key feature of Tanguar Haor’s nature, influencing its diverse flora and fauna and contributing to its rich biodiversity. The haor is home to a rich variety of aquatic and terrestrial flora that thrives in the wetland ecosystem. Its waterlogged environment supports a profusion of aquatic plants, including water lilies, lotus, and various submerged grasses. These plants play a vital role in providing habitat, shelter, and food for the area’s diverse aquatic fauna. Along the highway’s edges, you’ll find an assortment of riparian vegetation, such as reeds and sedges. These plants help stabilise the shoreline, prevent erosion, and offer refuge to various small mammals and birds. Mats of floating vegetation, including duckweed and water hyacinth, are common sights on the lake’s surface. These mats provide a crucial food source for herbivorous aquatic animals and create hiding places for fish. During the dry season, the area’s submerged grasslands emerge, providing feeding grounds for waterfowl and grazing areas for cattle. These grasslands are also important for the farm’s agricultural activities. It is home to over 200 species of fish. The seasonal flooding provides an ideal breeding environment for many of these fish, sustaining local fishing communities. The wetland is also home to various reptiles and amphibians, including snakes, turtles, and frogs. Some of these species

Read More

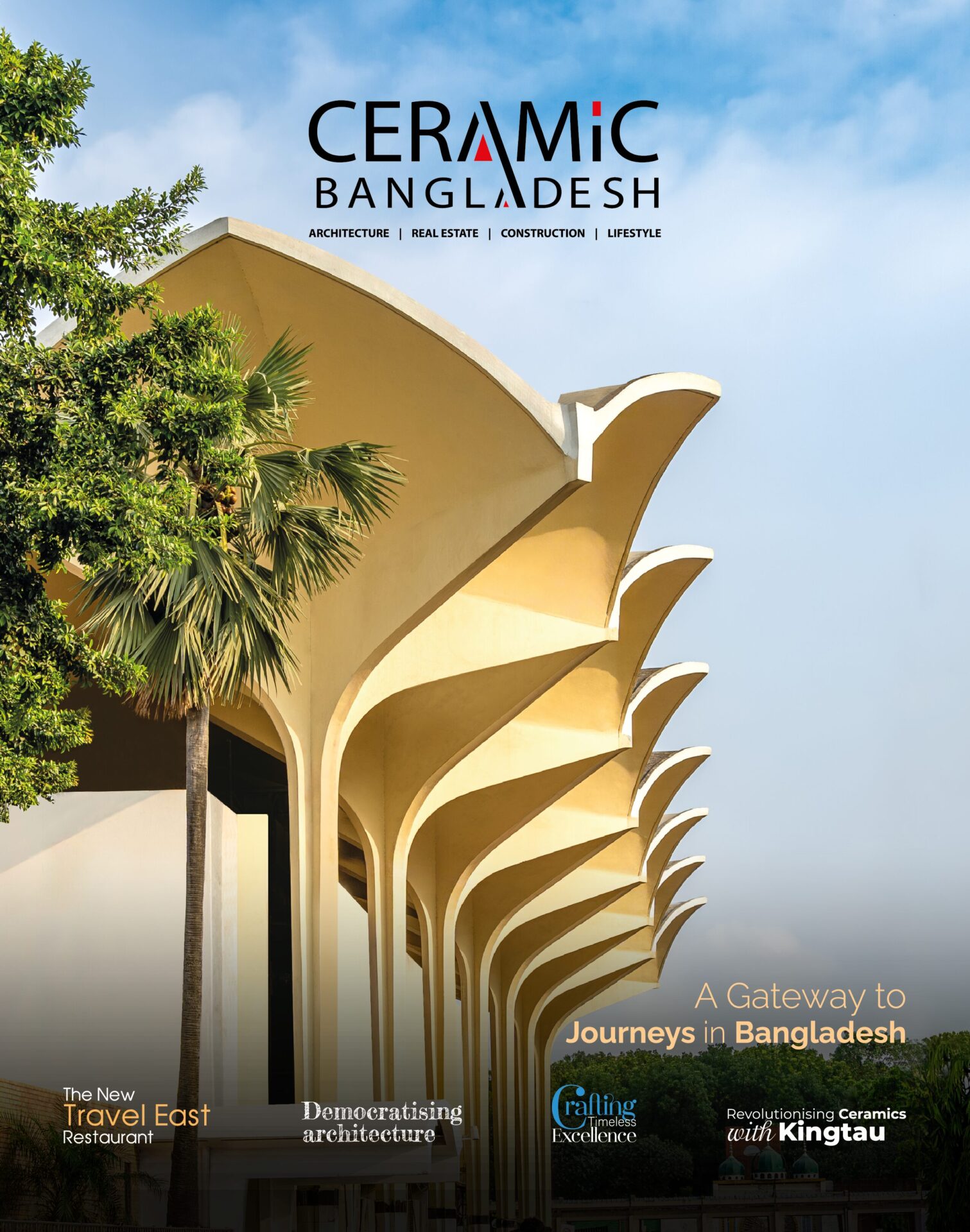

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far. Its rich history, architectural significance, and constant activity make it an iconic landmark. With a unique design and historical roots, Kamalapur Railway Station weaves together the fabric of Bangladesh’s rail network. The station’s significance has increased following the opening of the Padma Bridge. Kamalapur Railway Station (KRS), steeped in history, stands as Dhaka’s historic gateway. Its iron-clad colonial-era architecture evokes memories of a bygone era, a bridge between past and present. But Kamalapur is more than just a transit point; it embodies the spirit of a nation on the move—a pulsating heartbeat that reverberates across Bangladesh. Kamalapur Railway Station stands as a vital link in Bangladesh’s transportation network, connecting people, cultures, and commerce. As trains arrive and depart, the passengers weave intricate stories etched into the very walls of this magnificent station. Here, hope mingles with anticipation, dreams find their rhythm, and reunions unfold. The station’s bustling platforms witness resilience—the quiet strength of travellers forging ahead despite life’s twists and turns. And within its echoing halls, new beginnings take root, fueled by the promise of distant horizons. Kamalapur Railway Station, standing tall against the passage of time, is a living testament to Bangladesh’s architectural ingenuity. It’s not merely a physical structure; it’s a gateway to aspirations, connections, and the beating heart of a nation. As passengers step onto its platforms, they become part of a grand narrative—a journey that transcends mere destinations and becomes an enduring legacy of rail travel in Bangladesh. Architectural Marvel Kamalapur Railway Station stands as a captivating blend of modernity and tradition. More than a mere transportation hub, it represents an architectural marvel that seamlessly connects the past with the present. Designed by the renowned American architects Daniel Dunham and Robert Boughey (Bob Buie) of Louis Berger and Consulting Engineers Ltd. in the 1960s, Kamalapur Railway Station serves as a symbolic gateway to Dhaka. Daniel Dunham, a young architect fresh from completing his studies at Harvard’s Graduate School of Design (GSD), took charge of Berger’s fledgling Dhaka office. His task was to tackle an extensive backlog of new projects. The station’s architecture draws inspiration from both modernist principles and traditional neo-Islamic influences, as well as Bengali styles. It stands as a testament to Dhaka’s modern architectural spirit. Architect Daniel Dunham skillfully blended modernist elements with traditional Bangladeshi architecture. The station’s most striking feature is its parabolic shell roof—a true engineering masterpiece. Stretching over the platforms, this roof provides shelter to passengers. The lattice-like concrete structure fosters openness and allows natural light to filter through, creating a welcoming ambiance. Kamalapur Railway Station officially opened on May 1, 1968, during President Ayub Khan’s tenure. Its construction cost at the time was Taka 5 crores 30 lakh. When the value of one vori of gold stood at only 100 takas, A year after its inauguration, the Provincial Office of the Railway Postal Service found its new home within this remarkable station building. Design Features The station building is well-suited for tropical climates, providing protection from rainwater like an umbrella. It incorporates various functional spaces, including ticket booths, administrative offices, passenger lounges, waiting areas, and restrooms, all under an integrated canopy-based roof. The structure comprises 36 square domes supported by a total of 49 columns. Above these columns stands a roof featuring 36 slender concrete umbrella-type domes. Each column extends 59 feet high, branching out to support the roof. The open-air design capitalises on Dhaka’s cross breezes while safeguarding interior spaces from monsoon rains. The Kamlapur Railway Station’s thin concrete shell dome-umbrella design, completed by the consultants, has become a local icon, cherished by prominent architects as a cultural heritage piece. The parasol roof continues to define the station’s unique skyline. Architect Dunham immersed himself in Bangladeshi culture, learning Bengali and adapting to local craftsmanship and construction practices. Instead of designing an enclosed monolithic structure with mechanical heating and cooling systems, Dunham leveraged Dhaka’s tropical climate. His innovative roof system provides shade over the station’s offices and facilities, supported by a versatile field of columns. The construction technique involves thin concrete shells, which Dunham explored during his thesis at the GSD. After Dunham’s departure, architect Robert Boughey took over the post, designing tessellating concrete shells for the roof, reminiscent of pointed arches seen in Islamic architecture. These shells were cast on-site using reusable materials. Kamalapur Railway Station, with its remarkable parabolic shell roof, stands as an engineering marvel. This expansive structure spans the platforms, providing shelter to passengers. The station’s circular layout, boasting a diameter of 186 metres, centres around a soaring dome that reaches a height of 26 meters. Eight radial wings extend from the central hub, housing platforms, and tracks. The station’s architecture seamlessly blends modernist elements with traditional Bangladeshi motifs, reflecting the nation’s spirit. The concrete lattice structure allows natural light to filter through, creating an airy and open ambiance. High ceilings and spacious interiors enhance the feeling of grandeur. Kamalapur’s design prioritises functionality while maintaining aesthetic appeal. Geometric patterns, arches, and intricate details evoke the essence of Bengali culture. As a testament to Bangladesh’s identity and heritage, Kamalapur Railway Station stands proudly. The station is an engineering marvel that spans the platforms, providing shelter to passengers. Additionally, in other parts of the country, the Sylhet Railway Station in the north-eastern region and the Chilahati International Rail Station in the north-western part also feature a similar umbrella-like structure. These stations use national flower-shaped “shapla” shells supported by a forest of columns to cover their facilities. Historical Context Bangladesh Railway has been operating in the British period since 1862 in the eastern and western parts of the country, divided by the great river

Read More

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far.

Read More

Democratising architecture: Design that inspires awe and closeness to home

It was as though the beauty, heritage, and history of Mymensingh were plotting the becoming of Architect Masudur Rahman Khan – his birth city. Growing up in vast and glorious Mymensingh, which runs along Old Brahmaputra’s shores and birthed the Nakshi Kantha, Maimansingha Gitika and Shilpacharya Zainul Abedin, the BUET-alum Architect fashions his edifices from the collective memories of his childhood.

Read More

Crafting Timeless Excellence

BHL CERAMICS, the flagship brand owned by BHL GROUP Pvt. Ltd., has evolved over three decades as a dynamic business house and consumer products manufacturer. Since its inception in 2017, BHL Ceramic Co. Ltd. has become one of Bangladesh’s largest ceramic tile manufacturers, symbolizing artistry and creativity. The company’s mission is to reduce reliance on imported foreign tiles and boost domestic production, creating employment opportunities.

Read More

National Budget Thru Turbulent Waters Ceramic Industry Ignored in Budget

The recently unveiled Tk 7.97 trillion national budget for the 2024-25 fiscal year for Bangladesh aims to bringing a balance between controlling inflation and attaining economic growth. Economists, however, caution that higher borrowing and increased taxes on certain goods may prolong inflationary pressures. The budget’s reliance on domestic borrowing could lead to a “crowding-out effect,” restricting financing for businesses, particularly SMEs. Despite a target of 6.75 per cent GDP growth and plans to reduce inflation to 6.5 per cent, achieving these goals is deemed challenging. The budget proposes revenue of Tk 5.45 trillion with NBR tax amounting to Tk 4.80 trillion, leaving a Tk 2.56 trillion deficit to be primarily financed through bank borrowing, which may prompt money printing by the central bank and further inflation. Economists welcome the conservative approach but criticise the plan to increase electricity prices, potentially exacerbating inflation. The budget also includes initiatives for digital transformation and job creation in the IT sector, aiming to attract foreign investment. However, with foreign funding dwindling and significant tax increases on various goods, the effectiveness of these measures in achieving the stated economic targets remains uncertain. Bangladesh’s economic landscape is currently beset by numerous challenges, including stagnant investment, mounting debt repayment obligations, sluggish external sector growth, dwindling foreign exchange reserves, a fragile financial sector, tepid economic expansion, unemployment woes, and widening inequality, apart from soaring inflation. The proposed budget must confront immediate hurdles head-on through targeted budget allocations and fiscal policies. Although the budget is crafted for a single fiscal cycle, it serves as the conduit for translating the government’s economic strategies and political vision into reality. Hence, the proposed budget assumes paramount importance in tackling pressing issues such as safeguarding the interests of the impoverished, low-income, and lower-middle-income households, as well as addressing short to medium-term challenges such as fostering robust economic growth and curbing inequality. Given the prevailing economic exigencies, the FY2024-25 budget must pivot on four critical areas. Dr. Muhammad Abdul Mazid, a former chairman of the NBR, emphasised that this year’s budget cannot be compared to those announced in the past 8-10 years due to the turbulent global economy and several macroeconomic challenges facing Bangladesh. These challenges include a reserve crisis, dollar devaluation against the Bangladeshi Taka, higher inflation rates, and various governance issues. He asserted that overcoming the hurdles facing Bangladesh’s economy in the national budget will be difficult all of a sudden and in a shorter period. Instead, the government should focus on shaping a roadmap to navigate these crises. Dr. Mazid recommended that the budget should not follow the typical patterns of previous fiscal years; rather, it should include reforms in fiscal and monetary policy to address inflation, the dollar crisis, and reserve issues. Additionally, he suggested the formation of a banking commission to address loopholes in the banking sector. To curb inflation, the National Board of Revenue (NBR) could reduce duties on certain products, but effective market monitoring and management are essential to realise the benefits of such duty reductions. Strengthening the NBR’s capacity is crucial for enhanced revenue realisation. Moreover, Dr. Mazid stressed the importance of allowing concerned government organisations, such as the Anti-Corruption Commission (ACC), to operate independently to ensure effective governance. Ceramic Industry Overlooked The ceramic industry, part of the private manufacturing sector, has been significantly overlooked in the proposed national budget. Leaders of Bangladesh’s ceramic sector are urging for the removal of the 15 per cent supplementary duty on local tiles and the 10 per cent duty on domestic sanitary products. They point to rising raw material and gas prices, which have increased production costs. By eliminating these duties, they believe consumer prices would decrease. Md Shirajul Islam Mollah, a Member of Parliament and President of the Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA), had previously proposed removing additional duties on raw material imports and increasing tariffs on foreign ceramic products to the National Board of Revenue (NBR) before the 2024-25 fiscal year’s budget announcement. These measures would reduce imports, save foreign exchange, and boost employment in the country. Despite the relevance of these proposals, none were addressed in the budget. The domestic ceramic market, valued at Tk 8,500 crore. Although domestic companies control over 80 per cent of the market, they face tough competition from imports due to high production costs. On one hand, due to the dollar crisis, L/Cs (letters of credit) are not being opened for importing sufficient raw materials and machinery. Additionally, despite high prices, necessary gas for producing finished goods is not being supplied. On the other hand, amidst dollar crisis, the Bangladesh Bank has announced a second term reduction in cash incentives for ceramic exports—from 10% to 6%—within a span of six months. Meanwhile, the cost of doing business continuously increases. Over the past year and a half, Bangladesh has received loans from the IMF in three installments, but despite implementing several conditions attached to the loan, there has been no such improvement; rather than deterioration. Addressing Fiscal Challenges Economists believe, in the face of daunting economic hurdles, Bangladesh must embark on a prudent fiscal course to steer through turbulent waters. With inflationary pressures mounting and investment stagnating, the budget for the 2024-25 fiscal year demands meticulous attention to fiscal prudence. The government’s traditional reliance on banking sector borrowings to bridge budget deficits exacerbates interest payment burdens amidst constrained fiscal space. Hence, a judicious fiscal consolidation strategy, entailing restrained spending and bolstered tax collection efforts, emerges as imperative. Empowering the Social Sector While substantial investments have buoyed physical infrastructure, the social sector languishes due to chronic underfunding. Education and healthcare sectors, in particular, warrant heightened attention, with allocations in FY2024 falling woefully short of requirements. Fostering human capital development through increased expenditure on education, healthcare, and skills development is indispensable for sustainable growth and inclusivity. Facilitating Small Business Growth Small businesses, the lifeblood of the economy, must be empowered through facilitated access to finance. The banking sector’s burgeoning non-performing loans pose a formidable barrier to lending, stifling entrepreneurial endeavours. Elevating

Read More

A Guide before choosing your Sanitaryware

A home needs innovative ceramic ware and everybody looks for a touch of elegance, style, and personalisation. While the design of the ceramic ware is a personal choice within whatever fits the budget, ignored, sometimes, are the sanitary ware used. However, a lot has changed over the past few decades, as the market grows – People care not only for a well-designed bedroom, but also their bathroom.

Read More

Ayesha Sanaa Asif Tabani Steps up with Sophistication Upholding Legacy of Founding Fathers of the Pioneering Ceramics Company

As the Director of Mirpur and Khadim Ceramics, Ayesha Sanaa Asif Tabani has already been an influential figure in the ceramic industry, championing the integration of modern and innovative ceramic technologies. After completing her graduation and Master’s at Queen Mary University of London, she returned home to join the family business.

Read More

Revolutionising Ceramics with Kingtau Low Maintenance Ceramic Printing Machine

As cutting-edge technology enters into the ceramics industry, tile manufacturing processes are undergoing significant transformation. Only a few years ago, the idea of machinery capable of producing effects such as sugar textures, embossing, matte finishes, and mirror-like polish seemed unimaginable.

Read More