Mosque is not just a place of worship for Muslims; it’s the common most place of meeting and congregation of the followers of the religion of peace, Islam. It’s not only a holy place; it helps spread the message of love, friendship and brotherhood. Mosque is not merely a place that involves spirituality but also deals with worldly affairs; It’s more than that.

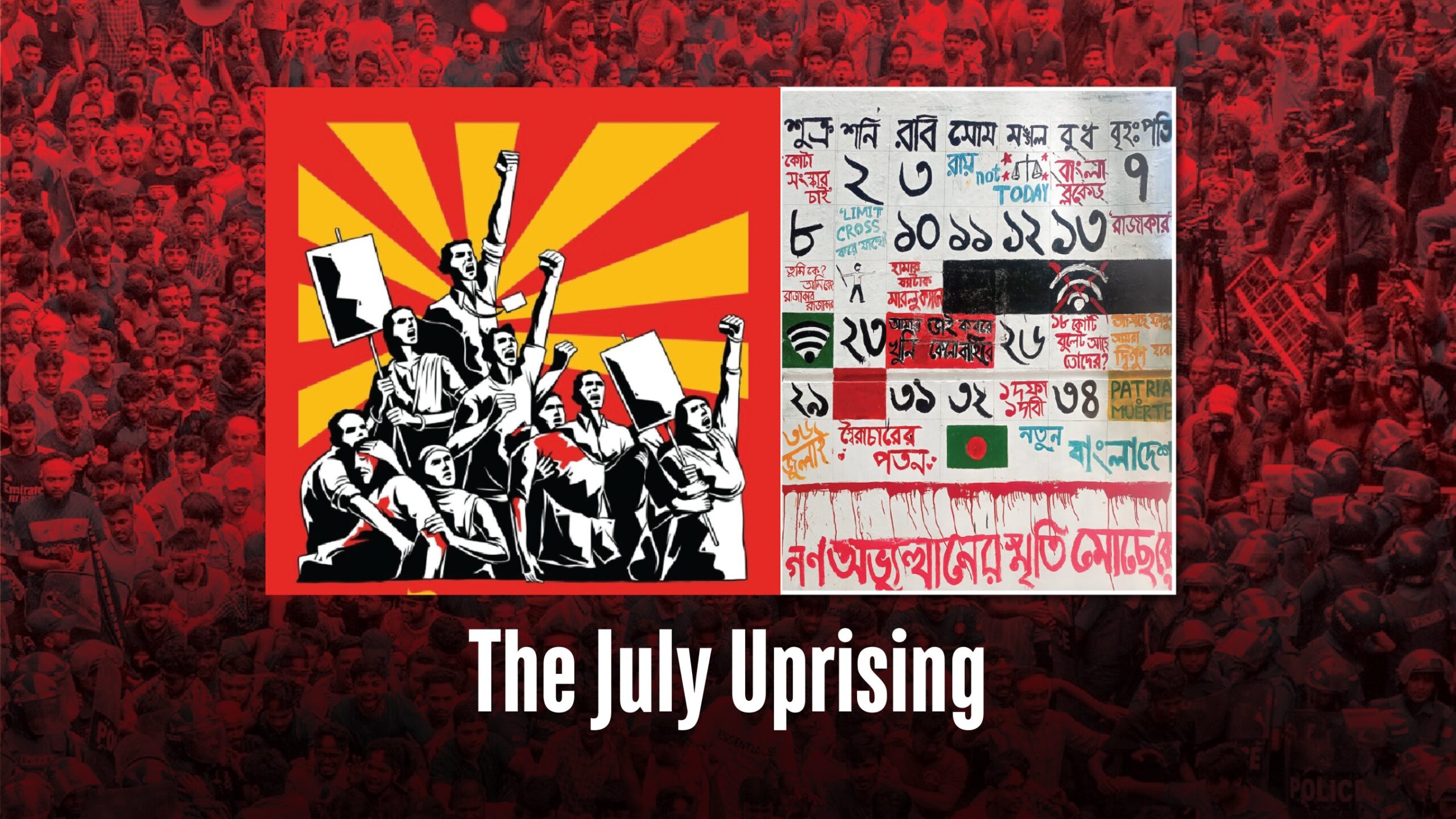

It began with a verdict. Not a speech, not a scandal—just a quiet ruling from Bangladesh’s judiciary. On June 5, 2024, the High Court reinstated a quota system for government jobs, reserving 56 percent of positions for specific groups, including descendants of freedom fighters. For many students, it felt like a door slamming shut. Within days, campuses across the country stirred with frustration. The movement that followed—Students Against Discrimination—was born not in fury, but in resolve. Their rallies were orderly, their chants measured. But beneath the surface, tension simmered. By early July, that tension boiled over. The protests evolved into the “Bangla Blockade,” a sweeping shutdown of roads and highways that paralysed the nation’s arteries. Buses vanished. Containers stacked up at ports. Supply trucks idled outside factories. Dhaka’s markets emptied as perishables spoiled in the heat. Exporters missed deadlines. Small traders watched their earnings evaporate. What began as a student movement had metastasized into an economic crisis. DEFINING MOMENTS June 5 | 2024 High Court reinstates quotas June 7-15 | 2024 Students begin peaceful rally, social media activism July 01 | 2024 Nationwide Bangla Blockade begins July 16 | 2024 Violent crackdown, leaving dozens killed Late July | 2024 FDI approvals drop 40%; export delays, gas shortages August 5 | 2024 Interim Government formed Sep–Dec | 2024 Interest hits 10%; ADP spending 49-year low Jan–Mar | 2025 Remittances peak; inflation eases; current account surplus Apr–Jul | 2025 Recovery phase: DSEX up 12.5%; exports rebound; MFS grows 64% August 5 | 2025 One-Year Anniversary A Nation on Edge On July 16 of 2024, the calm shattered. Security forces moved in with batons, tear gas, and live ammunition. The clashes were brutal. Ambulances raced through smoke-filled streets. Students lay bloodied on stretchers. Families camped outside police stations, desperate for news. Independent monitors reported hundreds injured and dozens dead. The government disputed the numbers. But the images—broadcast across television screens and social media—left little room for doubt. The shockwaves were immediate. Investor confidence collapsed. The Dhaka Stock Exchange saw its sharpest single-day drop in five years. Foreign direct investment approvals fell nearly 40 percent in the second half of 2024, according to the Dhaka Chamber of Commerce and Industry. The city, once buzzing with commerce, fell into a hush. Three weeks later on August 5, an interim government was announced, led by Nobel laureate Muhammad Yunus along with a panel of technocrats and civil society leaders. Their mandate: restore stability, rebuild trust, and prevent further economic unraveling. The Economic Aftershocks The July Uprising, as it came to be known, left no sector untouched. While the garment and ceramic sectors bore the immediate brunt, the ripple effects extended far wider. The banking system, already strained by years of financial irregularities, teetered on collapse. A post-uprising asset quality review revealed widespread non-performing loans and misappropriated funds, prompting the interim government to initiate recovery drives and liquidity injections. The Bangladesh Bank raised the policy rate to 10 percent to tame inflation and stabilise the exchange rate. Net foreign direct investment (FDI) dropped to a five-year low in 2024, as global investors cited political instability and opaque regulatory frameworks. The World Bank flagged Bangladesh’s deteriorating investment climate, while local chambers warned that the budget lacked a clear roadmap for restoring investor confidence. The energy sector faced dual shocks: gas shortages crippled industrial output, while privatisation efforts triggered an 18 percent hike in urban electricity tariffs, sparking fresh protests. The mental health toll was staggering. A Bangladesh Medical University seminar revealed that 82.5% of injured protesters suffered from depression, and 64% showed signs of post-traumatic stress disorder, underscoring the long-term human cost of the crisis. In the ceramic industry, 70 factories struggled to stay afloat. The Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA) reported that gas pressure—critical for kiln operations—dropped to as low as 2 PSI in some zones, far below the required 15. Production stalled. Costs soared. Their demands were precise: uninterrupted gas supply, priority allocation, compressor permissions, a five-year tariff freeze, and duty-free solar imports. None were met. The garment sector fared no better. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) confirmed shipment delays averaging two weeks during the unrest. Export Promotion Bureau (EPB) data showed a 7.8% decline in garment exports in Q3 of 2024. Buyers in Europe and North America have shifted orders to Vietnam and India. Smaller exporters faced penalties and lost contracts, according to the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA). The Foreign Investors’ Chamber of Commerce and Industry (FICCI) called for stronger rule of law, faster customs clearance, and smoother approvals. The Bangladesh Chamber of Industries (BCI) highlighted the plight of agro-processors, many of whom faced wastage and layoffs. Their appeal: concessional loans and tax relief. Even real estate, long seen as a safe haven, stumbled. The Real Estate and Housing Association of Bangladesh (REHAB) reported a sharp drop in property transactions, citing high registration fees, interest rates, and uncertainty over the Detailed Area Plan (DAP) revisions. Across industries, the message converged: without urgent reform, Bangladesh’s hard-earned gains risked slipping away. The Numbers Behind the Crisis The numbers told a sobering story. By late 2024, exports faltered, imports shrank, and growth slowed to its weakest pace in years. The disruptions that began with student protests soon seeped into every corner of the economy, from factories to food markets. Inflation surged through the summer, eroding wages and squeezing households already under strain. Though the pace of price rises eased the following year, the scars remained. Construction sites went quiet, housing demand collapsed, and long-promised infrastructure projects were postponed. The slowdown was no longer abstract—it showed in half-finished bridges and shuttered shops. Private investment also lost its footing. Business registrations dwindled, banks groaned under bad loans, and confidence withered. Even as revenue collection improved, it could not

The growth of the ceramic industry can also be attributed to historic back ground of the country, especially the people’s choice for attractive tablwares and show pieces. Records say, potters were actually popularised during the zamindars (landlords). They used to be patronised for making staues of goddesses, plates and other aesthetical items. Sometimes they were made to sculpt statues of the zamindar themselves. After the end of the zamindar system, they started making everyday household items for sales in the local market to earn a living. As pottery was the tradition, a section of people called kumar (potters) had for generaions embraced the occupation of making pottery items of household use. Their hand-made products could catch interest of the rural buyers. However, these proucts could neither meet demand of urban customers nor could they sustain because of their fragility, sun or oven baked products could not make a big headway outside the country. Recent history shows it was the initiative of an entrepreneur in the late 1950s that began production of earthen-ware using machine and thus machine-made clay craft appeared in the market. In fact, modern ceramic industry (machine-made) took a formal start with the functioning of Tajma Ceramic industry in Bogra in 1958. It was a small plant for porcelain tableware, and so production capacity of the factory was limited. Then came other entrepreneurs. The next to come was Mirpur Ceramic Works in 1962. Then Pakistan Ceramic Industry (later People Ceramic Industry) joined the market in 1966. After a gap of nearly two decades Monno Ceramics started production (tableware) in 1985. In the following year Bengal Fine Ceramics came to the scene. In 1997 Shinepukur Ceramics started production. As more entrepreneurs stepped in, they startd producing diversified items such as tiles, sanitary ware adopting new technology and using latest machinery and fine clay brought from abroad. Bangladesh Insulator and Sanitaryware Factory (BISF), Modhumoti Ceramics, Fu Wang Ceramic Industries and RAK Ceramics have placed themselves at the front in production of the items, not traditional, like tea-set or dinner sets. According to available statistics, about 95 per cent of raw materials for producing items are imported from different sources to maintain standards. The raw materials are imported mostly from China, Japan, Germany, New Zealand, Australia, Italy, Spain, Bulgeria, Vietnam, Thailand, South Korea and India. LOCAL CERAMIC INDUSTRY This is an industry that has experienced 200 per cent growth in production in the past ten years. Currently, there are 66 ceramic plants in three categories (Tableware 20, Tiles 28 and Sanitary ware 18) of products, operational in the country. Their products range. from table wares to tiles, sanitary wares to insulators and heavy and from clay to reflectors. The number of firms increased from 29 in 2010 to 66 in 2019. Investment in the sector amounts to more than US$1.1 billion, according to the Bangladesh Ceramics Manufacturers and Export- ers Association’s (BCMEA’s) estimate. More than half a million people, 40 percent of who are women, are directly and indirectly involved in the ceramic industry. Given the growth and demand of the sector, there has been a national focus on building skilled human resources for the ceramic industry. Now, Bangladesh Institute of Glass and Ceramics, Depart- ment of Glass and Ceramic Engineering at BUET and Rajshahi University of Engineering and Technology, and Faculty of Fine Arts at Dhaka University, offer various courses relating to ceramic products. The base of the industry is strong as the sector caters to 85 percent of the local demand and around 90 per cent of its 2018 turnover of Tk. 60 billion involved domestic market. The sector has seen a phenomenal local market growth from Tk 1225 billion in FY2010 to Tk 53.38 billion in FY2017. The industry’s production growth was record- ed at around 30 per cent in the past ten years. The country’s ceramics industry has also attracted foreign investments that have mainly come from China and the Middle-East countries. One foriegn and six joint venture companies include RAK Ceramics, Fu-Wang and China-Bangla Ceramics. Exports of ceramic products Although the country’s export volume is still not high in comparison to potential, about 20 companies are currently exporting ceramic products with 65 per cent value addition, according to available information. An amount of Tk. 4801 million came from the export market in 2018. It has maintained average 18 per cent growth in last 10 years. The sector attained a 32 per cent export growth in the year after the previous year’s growth of 16.6 per cent. The export market of ceramic products covers 63 countries. Main export destinations are EU countries, USA, Canada, New Zealand, Australia, Turkey and the Middle East. Industry insiders say the demand for Bangladeshi ceramic products in the international market is strong and there is reasonable scope for increasing exports of ceramic items. China and India are among major competitors in the international market for Bangladeshi ceramic manufacturers. However, labour cost has put Bangladesh in a strong position. Bangladeshi exporters can enhance exports if they are provided with supports to become more competitive in the international market. Given the global market of ceramic products worth US$400 billion, Bangladesh’s ceramic industry, if proper plans are taken and executed, has the potential to emerge as the ‘next RMG industry. Bangladesh’s expport share of the global ceramics market is less than 0.10% CHALLENGES AND WAY FORWARD Industry leaders say the country’s ceramic industry is facing some challenges, that are constraining its growth at home and in the export market. Of course, there is a scope for improve the production process making it more energy efficient. For that more funds need to be injected into the sector. Use of Nano-technology could be a good choice for entrepreneurs in Bangladesh. However, uninterrupted supply of natural gas, which is the main energy source for the industry, is a prerequisite for increasing production, according to sector leaders. Bangladesh’s domestic market for ceramic products is expanding due mainly to quality of products and price competitiveness. So supports should be