“It’s not about 10-hole bricks. It’s about a formula for a lifetime investment.”

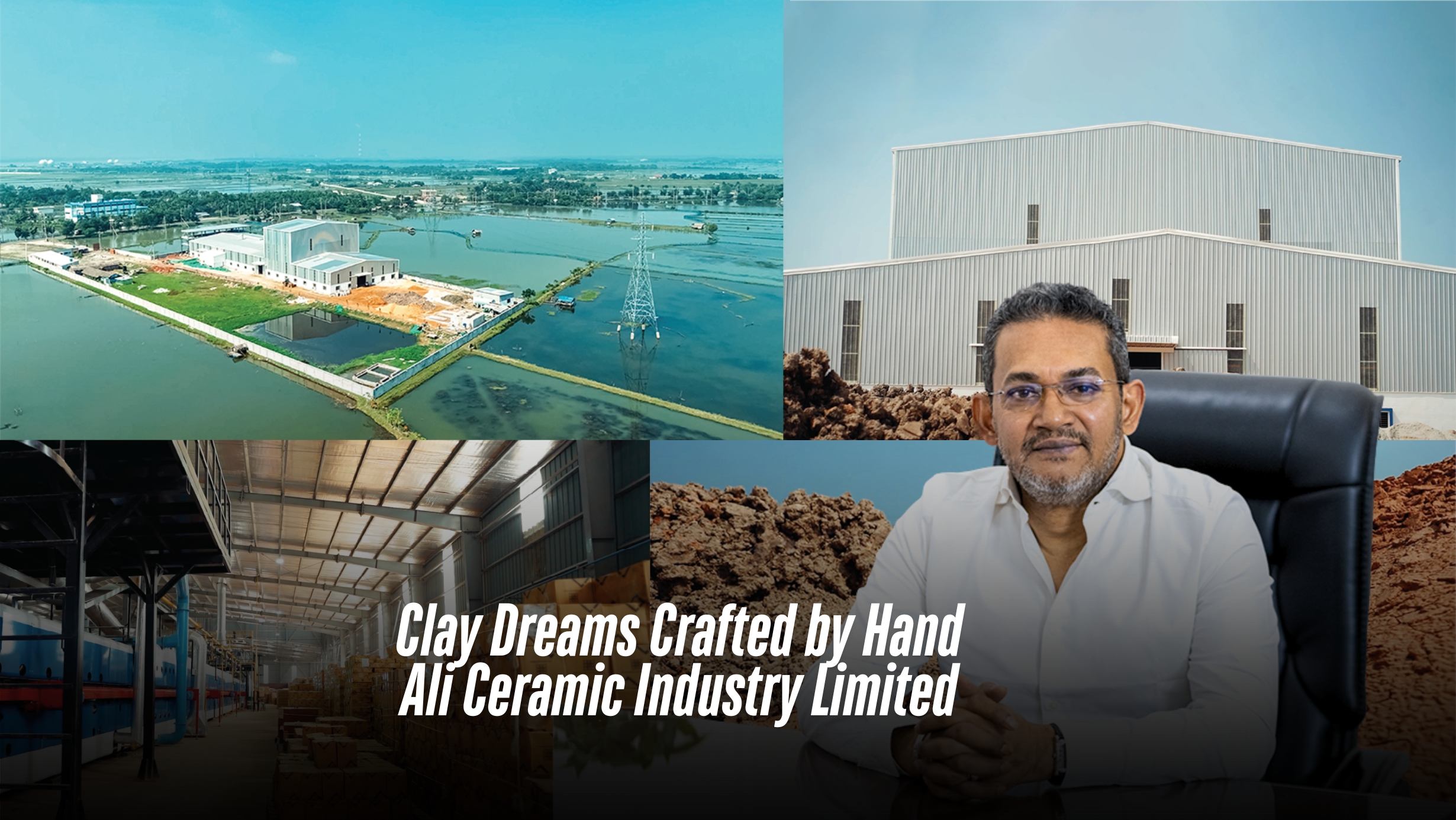

That is how Sakif Ariff Tabani, vice chairman of Mirpur Ceramics, Khadim Ceramics and Sunshine Bricks, describes the philosophy behind one of Bangladesh’s most ambitious ventures in the building materials sector.

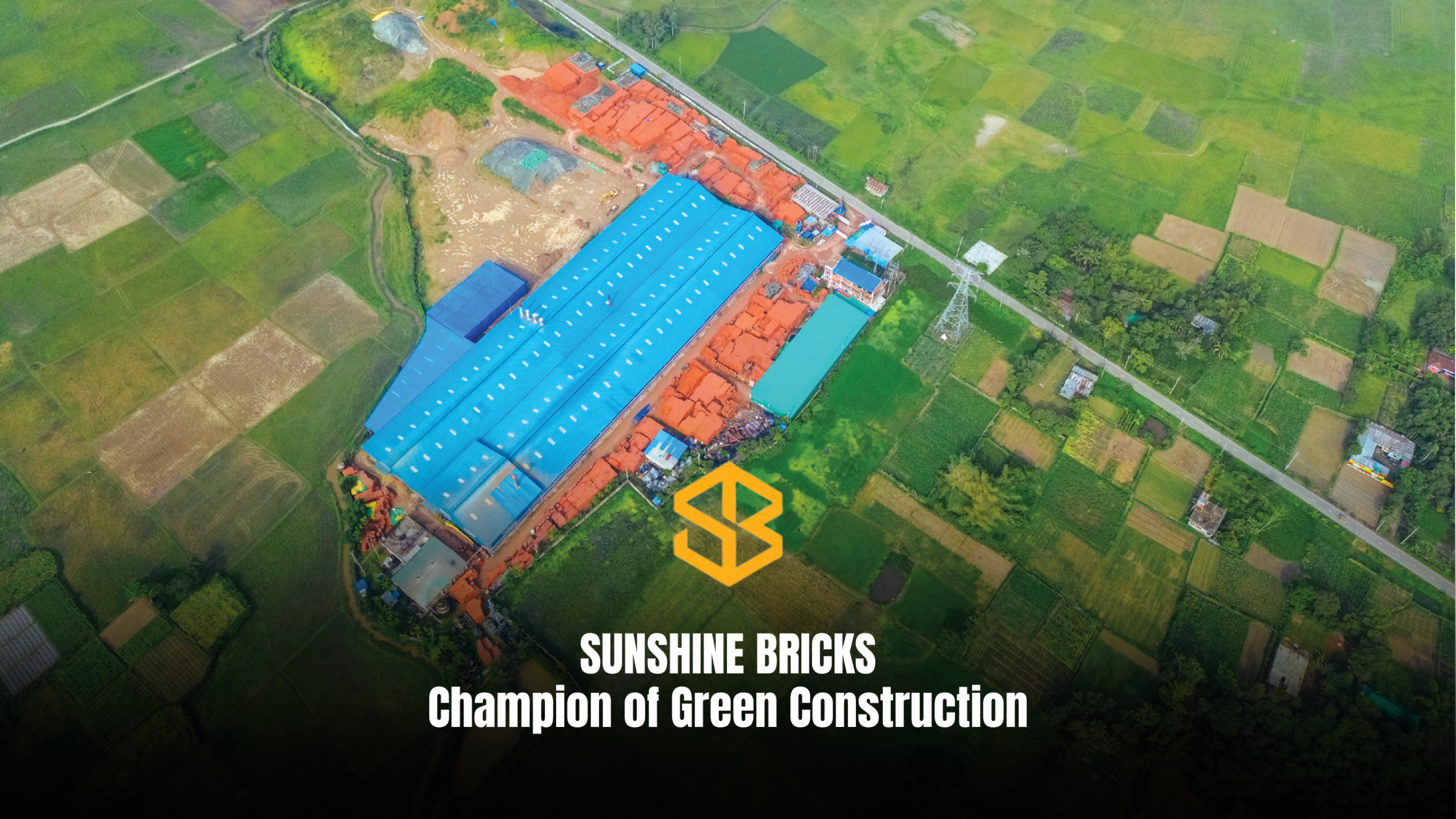

In a country where traditional red bricks have long dominated construction, Sunshine Bricks has emerged as a standout brand, reshaping expectations of durability, design, and sustainability.

From Habiganj to the National Stage

Sunshine Bricks was founded to revolutionise Bangladesh’s brick industry. Based in Habiganj, it serves growing demand for quality building materials nationwide.

As part of the Mirpur Ceramics group, alongside Khadim Ceramics—both renowned for manufacturing excellence—the company was created to fill a market gap for ceramic bricks and blocks that combine durability with aesthetic appeal.

“With a strong foundation in ceramics, Sunshine Bricks was launched to evolve into a leading brand in Bangladesh’s ceramic bricks and structural clay product industry,” said the vice chairman.

Traditional red bricks offered strength but little else. Sunshine Bricks changed that by investing in advanced technology and automation, producing materials that enhance structures while meeting the highest standards of quality.

“Over time, Sunshine has become a key player in domestic and international markets, offering sustainable, versatile products for diverse construction needs,” said Sakif Ariff Tabani.

The “Wonder Blocks”

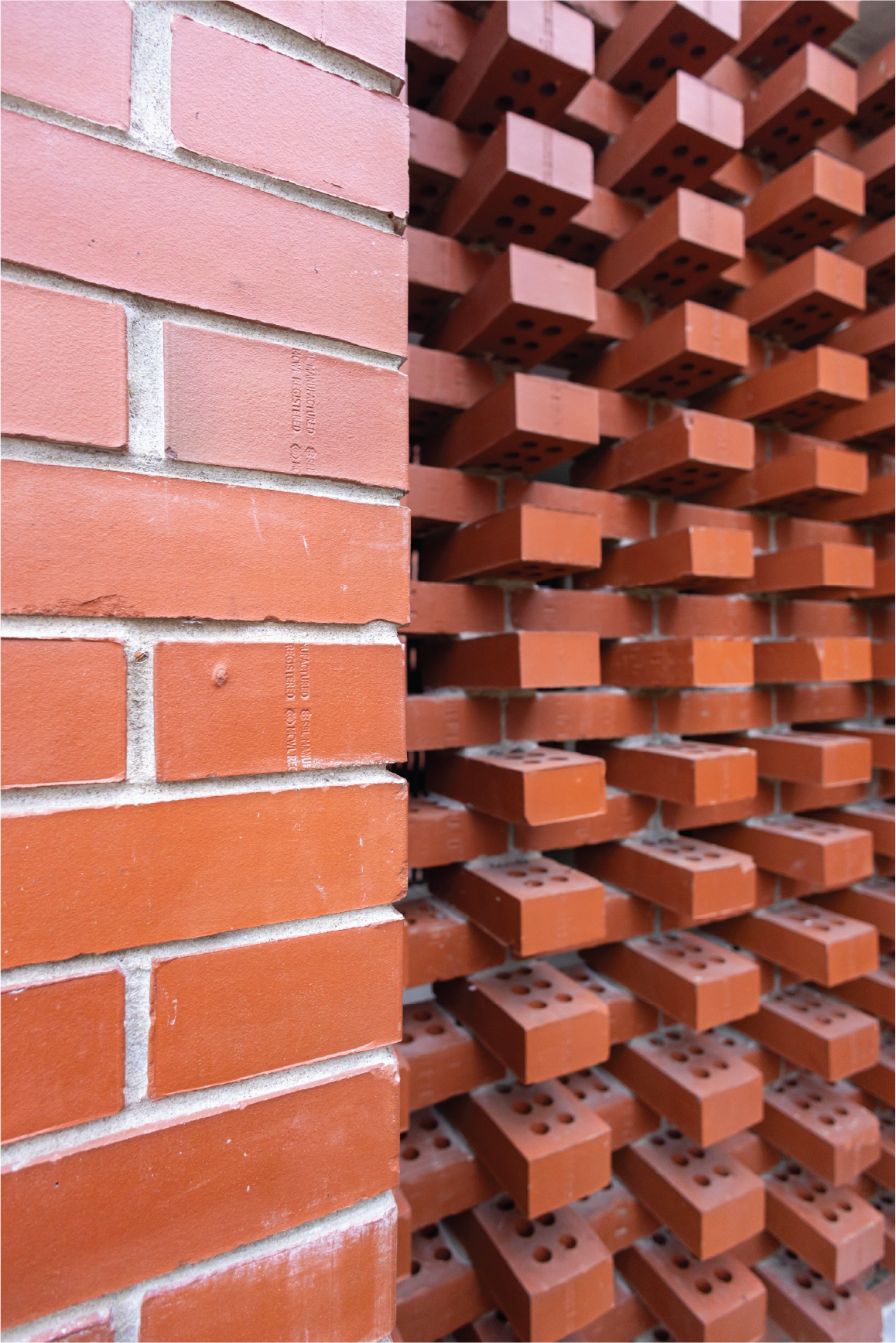

Sunshine Bricks is not a traditional auto-bricks company using Chinese technology. It is not about producing 10-hole bricks.

Instead, it is about creating products that deliver comfortable living conditions and cost savings in energy consumption. Certified for eco-friendly products, the company has positioned itself as a pioneer in sustainable building materials.

Among its most celebrated innovations are ceramic clay blocks, branded as “Wonder Blocks”. “These blocks are ideal for high-rise buildings, offering eco-friendly and energy-saving solutions,” said Sakif Ariff Tabani.

“Sunshine Bricks is also the first company in Bangladesh to produce facing bricks, coloured and textured bricks, and ceramic blocks—setting it apart from traditional manufacturers.”

“The coloured and textured bricks offer architects and developers a wide variety of designs and colours, enabling visually striking facades for residential and commercial buildings,” he said.

Produced using cutting-edge technology, these bricks ensure durability, weather resistance, and colour consistency. The ceramic blocks are designed for specific purposes such as soundproofing and lightweight building solutions.

Their lightweight nature reduces the overall weight of a structure without compromising strength, while their sound-insulating properties make them ideal for noise-sensitive areas. “By introducing these products, Sunshine Bricks is addressing modern needs such as energy efficiency, noise control, and aesthetic value,” said the veteran entrepreneur.

Technology at the Core

Sustainability is embedded in Sunshine Bricks’ production process. The company employs state-of-the-art technology to minimise environmental impact while ensuring high-quality output.

Its fully automated production line ensures precision and consistency, reducing waste and optimising resources.

A key innovation is Tunnel Kiln Technology, which is far more energy-efficient than traditional kiln methods. Tunnel kilns use controlled heat distribution, allowing for consistent firing and better energy use. This reduces the carbon footprint while ensuring higher-quality bricks with fewer defects.

Recycling processes are also integral. Water used in manufacturing is filtered and reused, minimising waste.

Raw materials are sourced responsibly, and the company incorporates alternative, eco-friendly materials into production. Sustainability is not an afterthought but a guiding principle.

The “Green Champion” Recognition

The decision to invest in Tunnel Kiln Technology was driven by efficiency and environmental responsibility. Traditional vertical kilns are costly and environmentally damaging. Tunnel kilns, by contrast, allow for consistent production with less energy consumption and precise temperature control. The result is higher-quality bricks with fewer defects.

The measurable gains have been significant. Energy consumption has reduced by about 30 percent, while emissions have decreased substantially. The use of alternative fuels in firing further lowers the carbon footprint.

These achievements earned Sunshine Bricks the “Green Champion” title, validating its efforts. For Tabani, however, the recognition is more than an accolade—it is a reminder that sustainability in manufacturing is necessary for long-term success.

Serving Diverse Markets

Sunshine Bricks serves customers across domestic and international markets. Its primary clients include government entities and public sector projects, supplying materials for major initiatives such as the metro rail, railway infrastructure, and education sector developments.

These large-scale projects demand durability, consistency, and high quality—hallmarks of Sunshine Bricks.

The private sector is equally vital. Developers, architects, and homeowners rely on the company for solutions that are both functional and aesthetically pleasing.

From luxury residences to commercial and mixed-use projects, Sunshine Bricks delivers products that meet diverse needs.

Internationally, Sunshine Bricks has expanded into the Middle East and Singapore, where demand for innovative, high-quality materials is rising. By tailoring offerings to local codes and design preferences, Sunshine Bricks has ensured adaptability—key to its success across markets.

A Legacy Since 1958

Sunshine Bricks is part of a proud legacy dating back to 1958, when Mirpur Ceramics first began producing bricks and building materials in Bangladesh.

Over the decades, Mirpur Ceramics earned a strong reputation for quality, reliability, and innovation. That experience and commitment are deeply embedded in Sunshine Bricks today.

Drawing on this rich history, Sunshine Bricks represents the modern evolution of Bangladesh’s brick and ceramics industry. Decades of expertise have been combined with advanced automation, eco-friendly technology, and modern design concepts to meet the growing demands of sustainable urban development.

Leading the Transformation

As Bangladesh urbanises, demand for sustainable, high-quality building materials is rising. Sunshine Bricks sees itself leading this transformation—driving the industry toward greener, smarter, and more design-oriented solutions.

The company also seeks to expand internationally, showcasing Bangladeshi innovation through exports to the Middle East and Southeast Asia. With over six decades of experience, Sunshine Bricks is not just building structures—it is helping build a more sustainable and progressive Bangladesh.

Redefining Building Materials

Rooted in Habiganj and tied to Mirpur Ceramics and Khadim Ceramics, Sunshine Bricks has become a standout in Bangladesh’s brick and ceramics industry. With customers ranging from government projects to international markets, its adaptability and ambition are clear. Ultimately, Sunshine Bricks is more than a manufacturer. It symbolises how tradition and innovation merge to create sustainable, versatile products.

As Tabani and his team look ahead, their vision is clear: Sunshine Bricks is not just building walls—it is helping build Bangladesh’s future.

Written By Nibir Ayaan