19TH ISSUE

Hands of a Hundred Thousand Stories

In a large workshop, the air carries the smell of moist clay and burnt oil. Before a single bone china plate reaches the station of Morium Begum or Kamrun Nahar, it has already gone through many steps. It has been shaped by machines, fired until it is as hard as stone, and covered in liquid transparent glaze. But in the final stage of its creation, the loud sounds of industry fade. The atmosphere becomes quiet and focused. Here, hands that know the journey from raw clay to finished vessel perform the most delicate work. These are the hands of artisans. They guide thin, fragile decals onto smooth ceramic surfaces. Each touch is important. Each movement is a blessing on products that will travel to dinner tables around the world. These hands belong to Morium Begum and Kamrun Nahar. They are senior workers, known as “Uchha Dakkhya”—high-skilled artisans. Their lives are deeply connected to this place. Morium has worked in the Export Decoration Department for 25 years. Kamrun has spent 22 years in Bone China Decoration. Their story is not about mass production. It is about careful, patient work and the building of a future. “I’ve been working here for 25 years,” says Morium. Her voice carries conviction. It is more than loyalty to a job. “It doesn’t even feel like we are at a job.” In Bangladesh, factory work is often temporary and difficult. Many workers move from one place to another, facing harsh conditions. So what makes this factory different? What unwritten promise has turned it into a home for these women for more than two decades? The answer is not only in the products they make. It is in the lives they have built through this work. A Day’s Work: The Rhythm of the Kiln In the wide world of ceramic manufacturing, the decoration department is special. It is where the object finds its soul. It is a major step before completion, the moment when a blank plate or cup becomes something unique. Morium and Kamrun are the guardians of this transformation. Their days follow a rhythm shaped by tens of thousands of hours of practice. The morning begins not with machines, but with quiet preparation. They clean their stations. They arrange their tools. They prepare the raw material: stacks of ceramic ware, called “oil” in factory language. Each piece is carefully wiped to make sure the surface is flawless. Then they turn to the decals. These are intricate designs printed on special paper. The paper is dipped in water. Slowly, the design loosens from its backing. It is ready to be transferred. This is the most delicate moment. They lift the fragile film of colour from the water and slide it onto the ceramic surface. The placement must be perfect. The design must flow with the curves of the cup or bowl. No machine can do this. Only memory, skill, and an artist’s eye guide them. Once the decal is in place, they use a simple rubber tool. With gentle strokes, they press out every tiny air bubble and drop of water. “The design is placed on the ware, and then a rubber tool is used to gently rub and set it,” Kamrun explains. Her hands mimic the motion. “After it’s fired, the design is permanent. It won’t even wash off.” The final firing, called Decoration Firing Kiln (oven), makes the design indelible. The decorated pieces go back into the furnace. The heat fuses the decal into the glaze. The process is technical, demanding, and repetitive. Yet the meaning of their work goes beyond mechanics. To understand why they have given their lives to this craft, one must look at the culture of the factory. More Than a Factory: A Foundation for Family For Morium and Kamrun, the factory has been the backdrop of their adult lives. They entered as young women. Over time, they became matriarchs. The culture of the workplace shaped them as much as the skills they learned. It is a culture built on respect. On the factory floor, there are no raised voices. No harsh commands. The sound is a low, cooperative murmur. This is very different from the verbal abuse that they hear is common in other industries. “We don’t speak to anyone harshly here,” Morium says. “We don’t even raise our voices.” This dignity is matched by flexibility. It allows them to be both workers and mothers. When their children had exams or when illness struck, they could take leave for 15 days, even a month. They did not fear losing their jobs. This security is rare. “It’s just like a government job,” Kamrun says. “We can take a month off if we need it. You won’t get that anywhere else.” Support is built into the system. There is a medical centre with doctors and nurses. There is a daycare for young children. But the strongest support comes from the community itself. The women call each other sisters. They share joys and sorrows. One story shows this bond clearly. At the wedding of a cook’s daughter, workers pooled money to help with expenses. The “chairman madam” attended the celebration. Management and staff stood together. In such moments, differences of religion or background disappear. They eat together. They work together. They share goals. This respect, flexibility, and community have created stability. It is the foundation on which Morium and Kamrun have built their lives. It is what allowed them to dream of something lasting for their children. From Artisans to Architects of the Future The true measure of their decades of labour is not in the countless plates and cups they have decorated. It is in the futures they are building. Their hands have shaped clay, but they have also shaped possibilities. Morium is now the sole provider for her family. Her husband, once a worker at

Read More

SUNSHINE BRICKS: Champion of Green Construction

“It’s not about 10-hole bricks. It’s about a formula for a lifetime investment.” That is how Sakif Ariff Tabani, vice chairman of Mirpur Ceramics, Khadim Ceramics and Sunshine Bricks, describes the philosophy behind one of Bangladesh’s most ambitious ventures in the building materials sector. In a country where traditional red bricks have long dominated construction, Sunshine Bricks has emerged as a standout brand, reshaping expectations of durability, design, and sustainability. From Habiganj to the National Stage Sunshine Bricks was founded to revolutionise Bangladesh’s brick industry. Based in Habiganj, it serves growing demand for quality building materials nationwide. As part of the Mirpur Ceramics group, alongside Khadim Ceramics—both renowned for manufacturing excellence—the company was created to fill a market gap for ceramic bricks and blocks that combine durability with aesthetic appeal. “With a strong foundation in ceramics, Sunshine Bricks was launched to evolve into a leading brand in Bangladesh’s ceramic bricks and structural clay product industry,” said the vice chairman. Traditional red bricks offered strength but little else. Sunshine Bricks changed that by investing in advanced technology and automation, producing materials that enhance structures while meeting the highest standards of quality. “Over time, Sunshine has become a key player in domestic and international markets, offering sustainable, versatile products for diverse construction needs,” said Sakif Ariff Tabani. The “Wonder Blocks” Sunshine Bricks is not a traditional auto-bricks company using Chinese technology. It is not about producing 10-hole bricks. Instead, it is about creating products that deliver comfortable living conditions and cost savings in energy consumption. Certified for eco-friendly products, the company has positioned itself as a pioneer in sustainable building materials. Among its most celebrated innovations are ceramic clay blocks, branded as “Wonder Blocks”. “These blocks are ideal for high-rise buildings, offering eco-friendly and energy-saving solutions,” said Sakif Ariff Tabani. “Sunshine Bricks is also the first company in Bangladesh to produce facing bricks, coloured and textured bricks, and ceramic blocks—setting it apart from traditional manufacturers.” “The coloured and textured bricks offer architects and developers a wide variety of designs and colours, enabling visually striking facades for residential and commercial buildings,” he said. Produced using cutting-edge technology, these bricks ensure durability, weather resistance, and colour consistency. The ceramic blocks are designed for specific purposes such as soundproofing and lightweight building solutions. Their lightweight nature reduces the overall weight of a structure without compromising strength, while their sound-insulating properties make them ideal for noise-sensitive areas. “By introducing these products, Sunshine Bricks is addressing modern needs such as energy efficiency, noise control, and aesthetic value,” said the veteran entrepreneur. Technology at the Core Sustainability is embedded in Sunshine Bricks’ production process. The company employs state-of-the-art technology to minimise environmental impact while ensuring high-quality output. Its fully automated production line ensures precision and consistency, reducing waste and optimising resources. A key innovation is Tunnel Kiln Technology, which is far more energy-efficient than traditional kiln methods. Tunnel kilns use controlled heat distribution, allowing for consistent firing and better energy use. This reduces the carbon footprint while ensuring higher-quality bricks with fewer defects. Recycling processes are also integral. Water used in manufacturing is filtered and reused, minimising waste. Raw materials are sourced responsibly, and the company incorporates alternative, eco-friendly materials into production. Sustainability is not an afterthought but a guiding principle. The “Green Champion” Recognition The decision to invest in Tunnel Kiln Technology was driven by efficiency and environmental responsibility. Traditional vertical kilns are costly and environmentally damaging. Tunnel kilns, by contrast, allow for consistent production with less energy consumption and precise temperature control. The result is higher-quality bricks with fewer defects. The measurable gains have been significant. Energy consumption has reduced by about 30 percent, while emissions have decreased substantially. The use of alternative fuels in firing further lowers the carbon footprint. These achievements earned Sunshine Bricks the “Green Champion” title, validating its efforts. For Tabani, however, the recognition is more than an accolade—it is a reminder that sustainability in manufacturing is necessary for long-term success. Serving Diverse Markets Sunshine Bricks serves customers across domestic and international markets. Its primary clients include government entities and public sector projects, supplying materials for major initiatives such as the metro rail, railway infrastructure, and education sector developments. These large-scale projects demand durability, consistency, and high quality—hallmarks of Sunshine Bricks. The private sector is equally vital. Developers, architects, and homeowners rely on the company for solutions that are both functional and aesthetically pleasing. From luxury residences to commercial and mixed-use projects, Sunshine Bricks delivers products that meet diverse needs. Internationally, Sunshine Bricks has expanded into the Middle East and Singapore, where demand for innovative, high-quality materials is rising. By tailoring offerings to local codes and design preferences, Sunshine Bricks has ensured adaptability—key to its success across markets. A Legacy Since 1958 Sunshine Bricks is part of a proud legacy dating back to 1958, when Mirpur Ceramics first began producing bricks and building materials in Bangladesh. Over the decades, Mirpur Ceramics earned a strong reputation for quality, reliability, and innovation. That experience and commitment are deeply embedded in Sunshine Bricks today. Drawing on this rich history, Sunshine Bricks represents the modern evolution of Bangladesh’s brick and ceramics industry. Decades of expertise have been combined with advanced automation, eco-friendly technology, and modern design concepts to meet the growing demands of sustainable urban development. Leading the Transformation As Bangladesh urbanises, demand for sustainable, high-quality building materials is rising. Sunshine Bricks sees itself leading this transformation—driving the industry toward greener, smarter, and more design-oriented solutions. The company also seeks to expand internationally, showcasing Bangladeshi innovation through exports to the Middle East and Southeast Asia. With over six decades of experience, Sunshine Bricks is not just building structures—it is helping build a more sustainable and progressive Bangladesh. Redefining Building

Read More

Architect Rashed and the Poetics of Practice

In the crowded clusters of Dhaka’s architectural offices—where every firm spoke in bold, predetermined tones—finding an original voice was never easy. For Architect Rashed Hassan Chowdhury, the journey began not with buildings, but with books and design experiments of all kinds. Encouraged by his elder brother to pursue architecture, he entered BUET carrying curiosity and a restless desire to make and learn. Even as a student, Rashed was never confined to one discipline. He moved fluidly between book design, graphic work, product design—anything that allowed imagination to unfold in tangible form. But the multiplicity of voices, the weight of tradition and pressure of trends, left him with a fundamental question: How does one discover one’s own architecture? Rashed’s answer, at least in the early years, was to do everything. His first role was as a researcher at BUET’s Green Architecture Cell, followed by a post as lecturer at the University of Asia Pacific. After office hours, he joined architects like Nahas Khalil, Marina Tabassum, and Mahmudul Anwar Riyaad on project-based work—each collaboration sharpening instincts and broadening vocabulary. And at night, in the chilekotha/attic of his brother’s office—with only a computer and printer—he began sketching the contours of his own practice. Sleep was rare, but happiness abundant. Eventually came the realization: energy without direction cannot sustain itself. “I was doing too much, but none of it was really going anywhere,” Rashed recalls. That reckoning pushed him to leave the safety of multiple jobs and commit to a singular vision. Out of that decision was born Dehsar Works—a multidisciplinary practice whose very name is simply the last-to-first spelling of “Rashed,” a gesture as honest and direct as the work it produces. Learning by Doing Dehsar Works is not merely an architecture office—it is a laboratory. For Rashed, design is not about formula but about process, about finding concept and clarity. “The design process excites me most. It still does, every single time,” he says. This philosophy is reflected in the kinds of projects he chooses and the way they evolve: adaptive reuse, experimentation with materials, finding beauty in imperfection, and above all, engaging with the everyday lives of users. The Blues Communications Office, a transformation of a warehouse into a bold new workspace, tested both his patience and creativity. The design called for a complex metal structure—one that contractors hesitated to take on. Instead of abandoning the idea, Rashed and his team decided to build it themselves. They formed a sister concern, aptly named Workshop, to execute the construction. Through trial, error, and persistence, they not only completed the project but also gained a wealth of knowledge about materials and making. Ajo Idea Space is perhaps the purest example of his ethos. Conceived as a café and gathering space, it was never meant to be a conventional air-conditioned box. Instead, it embraced openness, natural ventilation, and a certain looseness that invited people to linger. The pavilion-like structure, with its vaulted steel forms and porous screens, blurred the boundary between inside and outside. It embodied sustainability not as a checklist but as a lived experience: a place where people ate, conversed, and created in ways that felt organic. Another notable work is the Beximco Learning and Development Center, a lightweight, semi-circular hall framed with steel and clad in polycarbonate sheets. Here, the emphasis was on creating an affordable, sustainable, and flexible learning environment that could anticipate future uses. By designing with recyclability and climate responsiveness in mind, Rashed sought to redefine what corporate infrastructure could mean in Bangladesh. Similarly, the Artistry Marble & Granite Experience Center transformed an old warehouse into a gallery-like environment for natural stones. Rather than demolish and rebuild, the design preserved and reinterpreted the existing shell, reusing nearly half the materials. The result was a spatial narrative where light and texture interacted with surfaces, allowing visitors to experience stone not as a static product but as a dynamic material. Another iconic project of Rashed is Suvastu Rialto Tower, a contemporary commercial landmark in Dhanmondi. Developed by Suvastu Properties Ltd., the project embodies functionality, visibility, and refined contemporary design. Suvastu Rialto Tower is a 3-basement, ground plus 13-storey commercial building, developed on approximately 10 kathas of land. The vertical organization of the building efficiently accommodates parking, retail, and office functions, addressing both spatial optimization and urban density challenges. The architectural language of Suvastu Rialto Tower is distinctly modern, characterized by clean lines, transparency, and material contrast. The façade features a glass curtain wall system, combined with aluminium elements and contemporary detailing. The glass facades not only enhance the building’s aesthetic appeal but also maximizes daylight penetration, contributing to a pleasant and productive interior environment. A Philosophy of Effort Rashed is not shy about offering advice to the younger generation of architects. His words are sharp but encouraging: “Stop complaining and start enhancing your skills.” For him, the profession is not merely about constructing buildings but about learning by doing—whether in furniture, graphic design, or urban experiments. Bangladesh, in his eyes, is a land of vast opportunity, waiting for those willing to work with patience and integrity. “There is so much to do, but very few skilled people willing to put in the effort,” he says. The formal degree, while important, is not enough. Real growth, he believes, happens through curiosity, through the courage to try, to fail, and to learn. Toward a Different Future The story of Dehsar Works is, in many ways, the story of one architect’s relentless pursuit of authenticity. From a chilekotha room with a single computer to award-winning projects recognized internationally, the journey has been marked not just by structures built but by lessons learned. As Rashed continues to shape spaces that are adaptive, playful, and deeply contextual, he reminds us that architecture is less about monuments and more about moments: the

Read More

The Art of Playful Design A Look Inside BRAC University’s Child-Centric Sanctuary

A new chapter in early childhood care begins with the opening of the second BRAC University Daycare Centre, located in the vibrant Badda Campus of BRAC University, Dhaka. This thoughtfully designed facility serves as a sanctuary for children up to eight years old, offering a nurturing environment that prioritizes safety and development. Designed by Dwm4 Intrends, with an enchanting lighting scheme from Miro Lighting, the daycare centre is a dynamic and imaginative world where play, learning, and exploration intertwine, creating a joyful space for the children. A Palette of Softness and Imagination The daycare’s core design philosophy is built on a foundation of softness and playfulness. The space is defined by a serene Scandinavian colour palette of pastel shades—soft pinks, blues, and greens—that create a calming and inviting atmosphere. This selection of soft hues was a conscious decision to create a tranquil environment where children feel secure and at ease. Central to the design, this concept is also considered in all edges and volumes and is evident in the custom-made modular furniture, which features rounded edges to prevent bruises and generously cushioned surfaces for comfort. Thoughtful Zoning for a Comfortable Experience The daycare’s layout is thoughtfully divided into two primary zones: public and private. The public zone serves as a welcoming entry point for parents, where mothers can drop off their kids, change their clothes, or feed them. This area features an ergonomically designed washroom with sinks and toilets at child-friendly heights. The private zone is the heart of the daycare. It features a common activity area for all kids—a dynamic space for interaction, play, and learning. Adjacent to this is a sound-insulated nap room, a peaceful sanctuary exclusively for toddlers. This segregated room ensures a quiet and restful environment for sleep, with secure storage above the beds for personal belongings. This approach prioritises the comfort of children while ensuring that parents experience a sense of security and peace of mind. Materials in Design That Engage and Inspire The interiors reflect a calm design approach that is both impressive and functional. The vinyl floors are a durable choice, providing a soft, child-friendly surface that is easy to maintain. The walls are adorned with CNC-cut plywood cutouts that form geometric origami-style animals, such as giraffes and kangaroos, adding a unique texture and depth to the space. A notable feature of interior design is the vertical rock-climbing wall made from panels with child-friendly grips. This equipment helps the young children develop strength through adventurous play and is designed for those aged 4.5 years and older. This interactive design maximises floor space for other activities while promoting physical activity and overall development. When integrating an indoor climbing wall into a playroom, the child’s developmental stages and sensory needs were well-considered to ensure a stimulating and safe environment. Architect Daniel Haque shares, “Children at this age have a lot of curiosity and love to learn from playful shapes, so several playful interactive elements were incorporated in the design.” Overhead, snowflakes on the ceiling and house-shaped shelves on the walls introduce a sense of whimsy and also serve as visual cues to guide children. For hands-on learning, a pair of yellow, popsicle-shaped whiteboards is placed strategically, offering a fun way for children to express their creativity and learn. The pencil-shaped steel columns and child-sized furniture are used throughout the space, including a specially designed sofa that draws inspiration from the iconic “La Mamma” piece near the entrance, scaled down to suit the proportions of young children. The “La Mamma” furniture concept, also known as “Big Mama” or “Donna,” refers to Gaetano Pesce’s Up armchair. This iconic piece, introduced in 1969, is characterised by its distinctive shape and was initially made of foam. The armchair’s design has become a symbol of design and feminism, and a modern design classic. Prioritising Safety in Every Detail Safety was the number one priority throughout the design process. Architect Daniel Haque emphasises, “Special consideration was taken to soften all the edges; there’s no sharp corner here. Every edge has been wrapped with fabric. All switches and sockets are also placed above children’s height so that they can’t access them.” The furniture, floor, and wall materials were all selected with durability and safety in mind, proving that a playful and beautiful design can be achieved without compromising on security. This vibrant daycare was effectively designed by the lead architectural team of Mamnoon M. Chowdhury, Mahmudul Anwar Riyaad, Daniel Haque, and Md. Arifur Rahman. They worked in close association with architects Hasib Rehan and Md. Raduan Ahmed, and the construction was executed by Ar. Arifuzzaman Khan, Engr. Md. Omor Faruque, and Engr. Md. Tareq Rana, to create a practical environment specifically designed to meet the needs of young children. Written By Samira Ahsan

Read More

Nature Draped in Modern Elegance Story of BOHO Bangladesh

As we turn back towards nature and value the earth more than ever, are we equally ready to embrace green décor to adorn our spaces? Bangladesh has a rich tradition of ceramics, from glossy dinnerware to heritage terracotta. Yet when it comes to home décor, the exploration has often leaned on the familiar. Boho Bangladesh has taken on such a challenge with grace, weaving modern sensibilities into age-old elements of nature. Born by the sea in Cox’s Bazar, Boho Bangladesh grew from a vision to prove that sustainable living can be beautiful, versatile, and globally relevant. Their offerings span ceramics and pottery, organic and recycled textiles, home décor, and select limited-edition creations. To uncover the story of Boho Bangladesh—a brand redefining bespoke, eco-friendly home décor like never before, we sat down with its Chief Creative Officer and one of the co-founders, Poroma Shahrin, to trace their journey so far. Making of a green boutique lifestyle store: Partners in life and now in purpose, Poroma Shahrin and her better half ASM Asaduzzaman returned home, leaving their glorious career abroad, driven by a shared calling to nurture their roots. To them, BOHO was conceived from a desire to empower the raw, untapped resources of Bangladesh. They recognised that their nation’s rich, fertile land was capable of cultivating materials the world is now valuing more than ever. “The idea behind the brand was to reimagine heritage in its newest form—implementing innovation in ways that inspire young minds to engage with raw, natural materials that are often undervalued. While there are already a few pioneering brands in this field, I find their approach often lacks innovation. Synthetic products may look attractive at first, but they’re not sustainable. Our goal is to prove that natural, eco-friendly design can be just as appealing—when crafted with creativity and vision.” quotes Poroma Shahrin. With a display centre at The Muslin, Le Meridien Dhaka, Boho Bangladesh has been operating online since its inception. When asked about their online journey so far, Poroma said— “Our online presence has played a pivotal role in understanding people’s preferences, connecting with consumers, and navigating the kind of design direction they are drawn to. Although we believe Boho’s true spirit thrives in physical spaces. That’s why we’re launching a Dhaka studio store—envisioned not just as retail, but as a creative community for artisans and innovators. We’ve only executed about 30% of our vision, with much more planned.” Bespoke Green Décor: Is the Market Ready? “My husband and I often wondered if the Bangladeshi market was ready to embrace Boho Bangladesh’s vision. Most people in our country get influenced by a lot of factors in making their choices of lifestyle. The truth is, it’s still an emerging industry, but it’s evolving. People are gradually becoming more appreciative of sustainable décor, though greater education and awareness are still needed. Encouragingly, we’ve received strong validation from creative professionals—especially architects, artists, and interior designers—who truly recognize the value of our work,” said Poroma. Balancing Purpose and Profit: The team notes the irony that natural raw materials are currently the costliest, making it difficult to balance purpose with profit. They plan to address this with the launch of their studio store, which is designed to boost business sustainability and unlock new growth avenues. Furthermore, Boho Bangladesh is continuously refining production techniques to ensure product durability and reduce maintenance needs. This commitment not only minimises the risk of erosion but also guarantees customers high-quality, long-lasting, sustainable pieces. The entire production process is sustainable, ensuring safety by using nature-extracted colours and renewable resources, employing eco-friendly heating with zero carbon emissions, and recycling all production waste. The brand’s X-factor is an environment that encourages creativity and collaboration regardless of background. They strategically attract talent nationwide who bring hereditary expertise to their craft. A store by the beach Boho Bangladesh is planning an exciting expansion with a studio store in Cox’s Bazar. The location directly inspires their aesthetic, drawing from the Mediterranean bohemian lifestyle. Designed as a community platform rather than just a shop, the store will offer tourists a unique experience, featuring panoramic sea views and room for performances—a space where, as the founders note, “creativity flows best in nature”. Written By Fariha Hossain

Read More

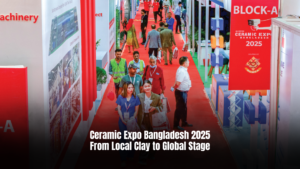

Ceramic Expo Bangladesh 2025: From Local Clay to Global Stage

Bangladesh’s ceramic industry has evolved from modest import substitution into a thriving manufacturing hub. More than 70 factories now produce tableware, tiles, sanitary ware, and ceramic bricks that meet global standards. The domestic market is worth Tk 8,000 crore annually, while exports to over 50 countries bring in nearly Tk 500 crore. In the past decade, production capacity and investment have surged 150%, fuelled by rising demand, sharper design, and steady technological upgrades. With cumulative investment topping Tk 18,000 crore and nearly 500,000 jobs created, ceramics have become a cornerstone of the nation’s industrial growth. Ceramic Expo Bangladesh 2025 Amid this momentum, Ceramic Expo Bangladesh 2025 showcased strength and ambition. Organised by the Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA), the fourth edition ran from November 27–30 at the International Convention City Bashundhara, Dhaka. The international exhibition brought together manufacturers, exporters, machinery and raw material suppliers, technology providers, and industry stakeholders. It drew strong local and international participation, hosting 300 exhibitors from more than 25 countries, including Bangladesh, China, India, Italy, Spain, Turkey, UAE, USA, Japan, South Korea, and Vietnam. Registrations topped 28,000, with visitors spanning architects, engineers, dealers, buyers, researchers, students, and officials. How the Expo Unfolded The BCMEA announced the much‑anticipated 2025 edition of the Ceramic Expo at a press conference on November 23 at the Dhaka Reporters Unity. BCMEA President Moynul Islam and Fair Organising Committee Chairman Irfan Uddin outlined key features—500 international delegates, three seminars, a job fair, B2B and B2C meetings, live demonstrations, spot orders, raffle draws, and new product launches. The briefing was attended by Senior Vice Presidents Md Mamunur Rashid FCMA and Abdul Hakim (Sumon), Vice President Rasheed Mymunul Islam, and Director Mohd Ziaul Hoque Zico. Syed Ali Abdullah Jami, director (sales & marketing) of Sheltech Ceramics Ltd., the principal sponsor of this year’s expo, joined the press meet alongside top officials of the three platinum sponsors: Didarul Alam Khan, head of marketing at DBL Ceramics Ltd.; Md Ashraful Haque, general manager (sales) at Akij Ceramics Ltd.; and Shahajada Yasir Arafat Shuvo, manager (brand) of Meghna Ceramic Industries Ltd. On November 27, Commerce Adviser Sk Bashir Uddin inaugurated the fair as the chief guest at a ceremony presided over by the BCMEA president. Partners SL Category Partner Name 1 Hospitality Partner Radisson Blu Water Garden Dhaka Regency 2 Accommodation Partner Amari Dhaka Best Western Plus Runway Crowne Plaza Grace 21 Smart Hotel Holiday Inn Intercontinental Hotel Lake Castle Platinum Grand Platinum Residence Renaissance Dhaka Westin Dhaka Chuti Resort 3 Gift Partner Hotel Lake Castle Grace 21 Best Western Plus Maya Platinum Grand Platinum Residence Dhaka Regency Hotel & Resort Ltd. Holiday Inn Dhaka Chuti Resort 4 International Event Partner Unifair Exhibition Service Co., Ltd. S.A.L.A. srl (ACIMAC) Messe Muenchen India Pvt. Ltd. 5 Knowledge Partner Bangladesh University of Engineering and Technology (BUET) Ceramic ISC 6 Strategic Partner Foshan Uniceramics Expo 7 Food Partner Platinum Grand 8 Official Magazine Partner Ceramic Bangladesh Magazine Asian Ceramics 9 Support Partner Export Promotion Bureau ASEAN Ceramics (Vietnam) TECNA KERAMIKA Ceramics CHINA 10 Media Partner The Business Standard Channel i Banglanews24.com Ceramic Focus Magazine Ceramic India Samakal 11 Young Engagement Partner JCI Bangladesh 12 Technology Partner Betafore 13 Wardrobe Partner FIERO 14 Connectivity Partner Amber IT Ltd. Days Full of Activities Every day of this year’s Ceramic Expo Bangladesh offered something new and innovative for visitors and industry professionals. Fresh B2B and B2C meetings unfolded across the venue, while seminars and discussions addressed pressing issues critical to resolving long‑standing challenges. After the inauguration of the expo, Commerce Adviser Sk Bashir Uddin, BCMEA President and Italian Ambassador to Bangladesh Antonio Alessandro along with top industry leaders toured the pavilions of the Ceramic Expo Bangladesh 2025. ACIMAC’s Project Manager Antonella Tantillo and Commercial Director of SACMI Imola S.C. Fabio Ferrari also visited the stalls. SEMINAR ONE The first seminar on “Energy Efficiency Strategies for Industry in Bangladesh: Challenges and Opportunities”, Engr. Toufiq Rahman, keynote speaker and assistant director of the Sustainable and Renewable Energy Development Authority (SREDA), reported national progress toward a 20% reduction in energy intensity by 2030, with 15% already achieved. Md Mamunur Rashid FCMA, senior vice president of BCMEA and additional managing director of X Ceramics Ltd; SM Monirul Islam, deputy CEO and CFO of IDCOL; and Md Imam Uddin Sheikh, general manager (production & marketing) of Petrobangla, shared their thoughts. Additional insights came from Tanvir Ebne Bashar, unit head of IDCOL, on flexible financing; Matheendra De Zoysa, COO of Omera LPG, on emissions concerns; and Babor Hossain, consultant of Khadim Ceramics. SEMINAR TWO The second seminar, held on the third day of the expo on “Global Market Strategies: Challenges and Opportunities for Ceramic Products”, featured keynote speaker Dr. Aditi Shams, associate professor of International Business at the University of Dhaka, who delivered a data‑driven analysis. Dr. Mohammad Monirul Islam, associate professor at the University of Dhaka; Dr. Amir Ahmed, associate professor and head of Real Estate at Daffodil International University; M. Mamunur Rashid, CEO of Artisan Ceramics Ltd; and Baby Rani Karmakar, director general of the Export Promotion Bureau, also spoke at the event. SEMINAR THREE On the third day of the expo, the most important seminar, “Skills Development for Sustainable Growth in the Ceramics Industry”, chaired by BCMEA President Moynul Islam, also vice chairman of Monno Ceramic Industries Ltd, brought together policymakers, development partners, and industry experts. Hari Pada Das, TVET institutional strengthening expert; Mina Masud Uzzaman, member for coordination and assessment and joint secretary of the National Skills Development Authority (NSDA); ANM Tanjel Ahsan, programme officer at the ILO; Dr. Nazneen Kawshar Chowdhury, executive chairman

Read More

bti focuses on affordable housing to achieve SDGs due time

The Building Technology & Ideas Ltd (bti), a real estate developing company in Bangladesh, started its journey in 1984. Over the years, the company has become a pioneer in the construction of high-rise and luxury buildings in the country. The company has already constructed around 450 buildings so far, and is working on 72 projects at the moment, and additional 100 projects are in pipelines. It has around 8,000 clients. “Thanks to maintaining customers’ commitment, accountability, delivering product timely, and ensuring quality products, the bti has made its today’s place in the country’s real estate sector,” Faizur Rahman Khan, managing director of the bti, shared his views with the Ceramic Bangladesh Magazine in an exclusive interview. He said the company’s motto is customer satisfaction. However, the bti started its journey with three projects in 1984. The company had six projects in 1990. How did bti expand its business? In 1992, it started building costlier luxury apartments in Gulshan at first, and in 1993 in Baridhara. It was a milestone for the real estate sector. Basically, the housing industry continued to expand after 2000. But in the 2007-08 year, the industry began to suffer owing to political unrest, Faizur Rahman informed. He stated that innovation is what sets the company apart from others. “We always try to bring innovation in every project. Customers are overwhelmed by our diversity. That is why they feel comfortable with the bti. Now it is a leader in aesthetic architecture.” In the 1990s, real estate companies faced a difficulty to buy land for housing as individual owners did not want to give up their lands easily. Besides, there were also complications regarding the registration of lands and flats. The bti took the initiative to build houses by sharing apartments with the landowners and approached the government for legislation. Later, only land registration was possible at the time. As a result, if you bought a flat, you would not be the owner of the land. “We started linking the flat ownership with the land ownership,” he said. He added that the Real Estate and Housing Association of Bangladesh (REHAB) has 500- 600 registered members. Of this, literally, there are 5-6 companies who are very active in the sector, and 10-12 companies who did one-two projects. The rest of the companies are ‘name only company’. “We cordially maintain commitment to customer, and hand over projects timely which are very crucial for the business. Even, we try to hand over projects before several months ago from agreement time for last few years. We don’t compromise in design and construction so we follow all codes, and rules of RAJUK and other organizations. We think so that clients are not faced any troubles in future,” the managing director said. Basically, bti serves three category of apartments – luxury apartment, classic, and affordable. The luxury apartments are generally built in Gulshan, Banana, Baridhara, and Dhanmondi areas. Classic apartments high demand to customers. The highest number of this apartments is in Bashundhara region where 40 mid-level projects are undergoing, and others are at Lalmatia, Mogbazar, and Segunbagicha areas. “Finally, affordable apartments—recently we started this as IMF and World Bank encourage it to ensure SDGs,” Rahman said. Generally, its apartment size is 500-600 squre feet. Its price is less than Tk 50 lakh. Customers can buy the apartment taking 70% of loan. So, bank loan should be fixed at reasonable interest rate for a long time. Ensuring safe and affordable housing for all Faizur Rahman highlighted that now the bti is focusing on affordable housing to achieve Sustainable Development Goal (SDGs) right time. In this regard, they discuss with a Japanese company to ensure Tk 200 crore investment in the industry. The affordable housing is addressed within the United Nation (UN)’s SDG- 11, which aims to make cities and human settlements inclusive, safe, resilient, and sustainable. Specifically, SDG target 11.1 by 2030 calls to ‘ensure access for all to ensure adequate, safe and affordable housing and basic services, and upgrade slums’. “To achieve the goal, all government’s officials should be cordial. There is needed a bribe, corruption, and hassles free business environment in the country,” he also commented. Real estate industry facing multiple challenges Faizur Rahman highlighted that the industry is facing multiple challenges including Detailed Area Plan (DAP). The DAP should be practical. There is a big gap between academia and industry. To make it successful, there is needed consultation with the realtors. The Floor Area Ratio (FAR) should not reduce such level which will create a problem to give space for the people as it is a density population country. Investment in projects has become slow as the government halted many mega projects. Besides, there is political instability right now. So, the demand for apartments also decline. Potential of ceramic products in housing industry Faizur Rahman said there is huge potential of ceramic products particularly tiles in real estate industry. The demand for the items rapidly increased in both local and international markets. The products contribute to bring attractive, and save time in construction of buildings. Written By Rafikul Islam

Read More

FIERO’s Custom Clothing and Changing Urban Rituals in Bangladesh

What began as a modest idea in mid-2017—to provide home-service tailoring for people constrained by time—has, within eight and a half years, evolved into FIERO, a leading bespoke and made-to-measure clothing practice in Bangladesh. Rooted in Dhaka yet informed by global traditions of craftsmanship, FIERO reflects a quiet shift in how custom clothing is conceived, experienced, and delivered in the local context. To understand this shift, it is necessary to look back at the tailoring culture that shaped earlier generations. For decades, the ritual was familiar: men accompanying their fathers or uncles to fabric stores overflowing with rolls of cloth in every imaginable colour and quality—good, bad, and everything in between. One would select a fabric, have it cut, leave measurements behind, and depart. The process was largely transactional, often hurried, and rarely comfortable. Instead of functioning like a conventional store, the tailoring journey is reimagined as something closer to being hosted in a living room. Guests are encouraged to slow down, sit comfortably with a cup of tea, and engage in unhurried conversation about what they wish to make. Founder and Managing Partner Syed Easir Alam (Yasir) explains that this sense of hospitality is intentional. “We welcome our guests with tea when they enter. Then we sit together and discuss fabric options. Our store is not a display centre of fabrics,” he says. With globalisation and changing lifestyles, bespoke clothing gradually became repositioned as a more exclusive, almost privileged service. Yet demand persisted across social strata—from lower-middle to upper segments—particularly among professionals, corporate executives, and business leaders for whom clothing remains closely tied to identity and confidence. FIERO emerged at this intersection of inherited practice and contemporary expectation. While a few brands in Bangladesh now offer bespoke services, FIERO’s approach centres less on retail and more on process. Rather than racks and shelves, fabrics are curated through carefully organised swatch books. Sourced from different parts of the world, these materials offer a range of quality and variety rarely available locally. Today, the collection includes more than 10,000 fabric options. Displaying such a volume physically would be impractical, but through swatches, clients can compare textures, weights, and finishes—many of them high-end, super-fine fabrics not commonly found in Bangladesh. This working method directly influenced the spatial decisions behind FIERO’s flagship space on Gulshan Avenue. The previous location, less than half the size, was inadequate for hosting multiple guests comfortably. The new space was conceived not merely as a store, but as a place where time could be spent without pressure. Guests may book appointments or walk in, settle into the space, and look out over the city. The intention is clear: no rushing, no crowding—only a calm environment that feels closer to home than to retail. Once fabrics are selected, measurements are taken by an in-house tailor to maintain consistency and quality. Design decisions follow, guided by a comprehensive catalogue that brings together options across categories—from trousers and jackets to full suits. Rather than prescribing styles, the process encourages clients to participate actively, choosing details that align with their needs and lifestyles. The interior design reinforces this approach. “We needed a place that felt like home—spacious and breathable,” says Alam. The layout prioritises openness, uninterrupted sightlines, and abundant daylight. Visual connections between inside and outside are maintained, allowing the city to remain a constant backdrop. A small book corner acknowledges FIERO’s largely educated and corporate clientele, for whom reading and reflection are familiar parts of daily life. In an era when people are increasingly particular—even about sleepwear—custom clothing demands attention to detail and emotional comfort. FIERO recognises that good decisions are made in good moods, and that environment plays a crucial role in the making process. Designed by Kaleek Consultants, the interior balances functionality with warmth: a continuous open space, multiple lounge-like seating areas, fitting rooms, tailoring zones, and work areas, all unified by light, views, and calm. FIERO’s story is not only about clothing. It is about rethinking bespoke tailoring in Bangladesh as a process shaped by time, comfort, and thoughtful design as much as by craftsmanship—offering a grounded example of what “Made in Bangladesh” can signify today. Written By Sadia Tarannum

Read More

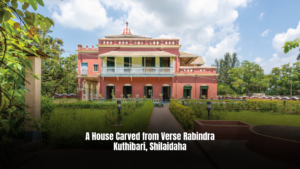

A House Carved from Verse Rabindra Kuthibari, Shilaidaha

In the quiet folds of Kushtia’s Kumarkhali upazila, just 20 kilometres away from the bustling town, stands a house that is not simply made of brick and timber—but of silence, river wind, and the rhythms of poetry. Rabindra Kuthibari, Shilaidaha, with its gentle red hue and pyramid-shaped roof, rises like a memory from the past. For those who follow the life and legacy of Rabindranath Tagore, this place is not just a historical site—it is a chapter from his soul. Long before the poet arrived, the land bore a different name—Khorshedpur. During the British colonial era, a European indigo planter named Shelly established a factory here. The convergence of the Gorai and Padma rivers created a swirling eddy nearby, a dah, which soon lent the village its new identity—Shellydaha. Over time, the name softened and reshaped itself into what it is today—Shilaidaha. It was in 1807 that Dwarkanath Tagore, Rabindranath’s grandfather, came into ownership of the estate through a will executed in his favour. And in the November of 1889, a young Rabindranath first arrived to take charge of his family’s zamindari. What was meant to be a duty, however, unfolded into something far deeper. Shilaidaha became the poet’s retreat, his muse, and his companion. Between 1891 and 1901, he stayed here on and off, and during those years, he wrote not only with discipline but with devotion. This house, nestled amidst orchards and ponds, framed by jackfruit and mango trees, heard the first lines of Sonar Tori, Chitra, Chaitali, and Katha O Kahini. The silence of the village, broken only by birdsong or boat horns on the river, gave birth to the songs of Gitanjali, fragments of Gitimalya, and most of Naibedya and Kheya. It was in this very setting, in 1912, that Rabindranath began translating Gitanjali into English. The poems—spiritual, meditative, and deeply intimate—were not just translations but transformations. In Shilaidaha’s peaceful stillness, words found a new cadence. By the time the English Gitanjali reached Europe, it was carrying the scent of Bengal’s riverbanks and the soul of this quiet estate. In 1913, this work earned him the Nobel Prize in Literature—making him the first non-European to receive this honour. But in many ways, the prize had already been won in these silent evenings spent under Shilaidaha’s sky. The house itself is unlike any ordinary zamindar residence. Built in the Indo-Saracenic style, the three-storied bungalow, with its sloping roofs made of Raniganj tiles and open balconies on every floor, seems more like a shelter for ideas than a place of power. Its walls, some say, were inspired by the gentle waves of the Padma River. Even now, though the Padma has changed its course and moved away, the spirit of the river lingers around the Kuthibari like a forgotten song still echoing in the wind. From its upper balcony, one could once see both the Padma and the Gorai flowing in opposite directions—a view so rare and sacred that it stirred the deepest parts of the poet’s being. Each morning, Rabindranath would sit by the window or wander into the yard, observing the life of villagers—their laughter, their burdens, their rhythms. From them, he drew characters, emotions, and philosophies. He often sat beside the pond under the shade of the Bakul tree, or climbed into his boat—the bajra—and let the wind on the Padma guide his thoughts. The poet did not write merely about the world; he wrote with the world. This house was no stranger to voices of genius. Friends and contemporaries from Bengal’s vibrant intellectual and cultural circles would gather here, filling the rooms with music, debate, laughter, and ideas that would shape the course of a generation. Among them were Sir Jagadish Chandra Bose, whose revolutionary experiments in science had already gained acclaim, Dwijendralal Roy, the dramatist and composer whose patriotic songs stirred Bengal’s heart, and Promoth Chowdhury, whose essays and prose defined modern Bengali literature. Others like Mohitlal Majumdar and Lokendranath Palit also visited, finding in Shilaidaha both serenity and stimulation. These gatherings were not formal assemblies, but soulful retreats—quiet celebrations of art, knowledge, and the interconnectedness of all thought. The nostalgia of this place seeps through every doorframe. Even now, within the walls of the restored Tagore Memorial Museum, visitors stand before the poet’s bed, wardrobe, writing chest, and even the commode brought from England for his use. Each object whispers stories of a time when poetry lived here—not just on paper, but in the stillness between footsteps, in the rustle of mango leaves, in the soft splash of oars against water. The house is surrounded by an expanse of trees, some now older than memory itself. The flower garden continues to bloom seasonally, much like the poet’s verses—timeless and regenerative. Two buildings stand near the gate, named Gitanjali and Sonar Tari, housing a library, an auditorium, and an office. During the celebrations of Tagore’s birth and death anniversaries, the grounds come alive again—with music, recitations, and the mingling of hearts drawn to his legacy. Though the Padma has drifted away and the house no longer sees boats docking at its ghat, the essence remains unchanged. The wind still carries the same softness. The pond still holds reflections of a poet who once stood beneath a mango tree and wrote not just about Bengal, but for Bengal. Rabindra Kuthibari, Shilaidaha is more than a destination. It is a feeling—a pause in time. It is where literature took breath, where rivers became metaphors, and where Rabindranath Tagore found both solitude and song. For those who visit, it is not merely about seeing where he once lived. It is about walking into the pages of his life. Written by Samia Sharmin Biva

Read More