Between depleting natural resources and a dire need to conserve and restore nature is the upsurging imperative to ensure industrial growth. An emerging economy like Bangladesh needs urgent transition to a more greener approach when it comes to growth, a resurgence of a 52 year-old nation.

Focusing On Ceramic Industry

While the product itself is environment-friendly, the production process causes 0.29 tonne of CO2 emission for every tonne of ceramic produced. Following a worldwide awareness, nations are turning to sustainable approach. The ceramic companies in Bangladesh are adapting to it as well.

On a broader perspective, the 2023 SDG report says, one in every two countries lacks an effective framework for sustainable water management. From 2015 to 2020 there has been a slight improvement when it comes to SDG implementation. This, however, needs to be doubled if we want to meet the global goals. As Bangladesh has pledged to implement SDGs and comply with global standards, its ceramic sector has seen sustainable growth.

DBL Ceramics, a concern of the DBL Group, is a young ceramic manufacturer, established in 2017. In a very short period of time, the company has reached the current position as one of the top manufacturers of ceramic tiles. DBL tiles are made for almost every surface –regular floors, high-endurance/areas with heavy traffic, gymnasiums and so on. The past few years saw substantial growth of the company which has over 160 dealers and 6 display centres in Dhaka, Chattogram, Rangpur, Sylhet and Barishal, with plans to expand to Khulna and Rajshahi. DBL has also made significant investments in reusable resources and waste water management, amongst other sustainable initiatives. In an attempt to reduce waste water, DBL has installed waste water treatment plants capable of treating 18,720 cubic meters of wastes by product everyday.

State-of-the-art machineries at DBL

SACMI kilns to turn clay to ceramic, Ball Mills for fine grinding, and Air Power glazing line–most of DBL’s machineries are energy efficient motors. They have inverters, energy cogeneration system, machines to reuse energy from kilns and dryers, along with other equipment to reduce wastes. To add a bit more automation to the mix, the company has Techno Ferrari for handling and storage. Ceramic Bangladesh Magazine visited DBL’s Gulshan office recently and sat with its head of operations Md. Bayazed Bashar to discuss his experience in the industry, future plans of the company, export difficulties, and more issues. DBL is a relatively young company but has fast become one of the top tier tiles manufacturers in the country. It has some of the best showrooms in the country and provides clients with an immersive experience, allowing them to visualise the product better.

“Ever since I joined DBL, I’ve had unwavering support from our management. I was on project implementation when I joined, and I am thankful for the faith our management had in us, which consequentially resulted in our performance and growth” said Mr. Bashar. “DBL ceramics is the first diversified project for the DBL Group. We have an R&D (research and development) team working on innovation and we have become one of the top brands within a short time. We uphold our standards through our service quality and innovation,” he said. In terms of growth, DBL has been adding a production line every alternative year, and now has the capacity of producing 35,000 square meters per day from the initial capacity of 8000 sqm. The conversation ensued as we talked about the initial steps of a career in the ceramic industry, Mr. Bashar said, “It’s very difficult to find a mentor who can guide you in the earlier years of your career, especially after graduation. A mentor can help you choose the right track, giving you opportunities, and helping you polish yourself. I’m really happy to have had the opportunity to join DBL Ceramics, and found my own mentor here.”

“Ever since I joined DBL, I’ve had unwavering support from our management. I was on project implementation when I joined, and I am thankful for the faith our management had in us, which consequentially resulted in our performance and growth” said Mr. Bashar. “DBL ceramics is the first diversified project for the DBL Group. We have an R&D (research and development) team working on innovation and we have become one of the top brands within a short time. We uphold our standards through our service quality and innovation,” he said. In terms of growth, DBL has been adding a production line every alternative year, and now has the capacity of producing 35,000 square meters per day from the initial capacity of 8000 sqm. The conversation ensued as we talked about the initial steps of a career in the ceramic industry, Mr. Bashar said, “It’s very difficult to find a mentor who can guide you in the earlier years of your career, especially after graduation. A mentor can help you choose the right track, giving you opportunities, and helping you polish yourself. I’m really happy to have had the opportunity to join DBL Ceramics, and found my own mentor here.”

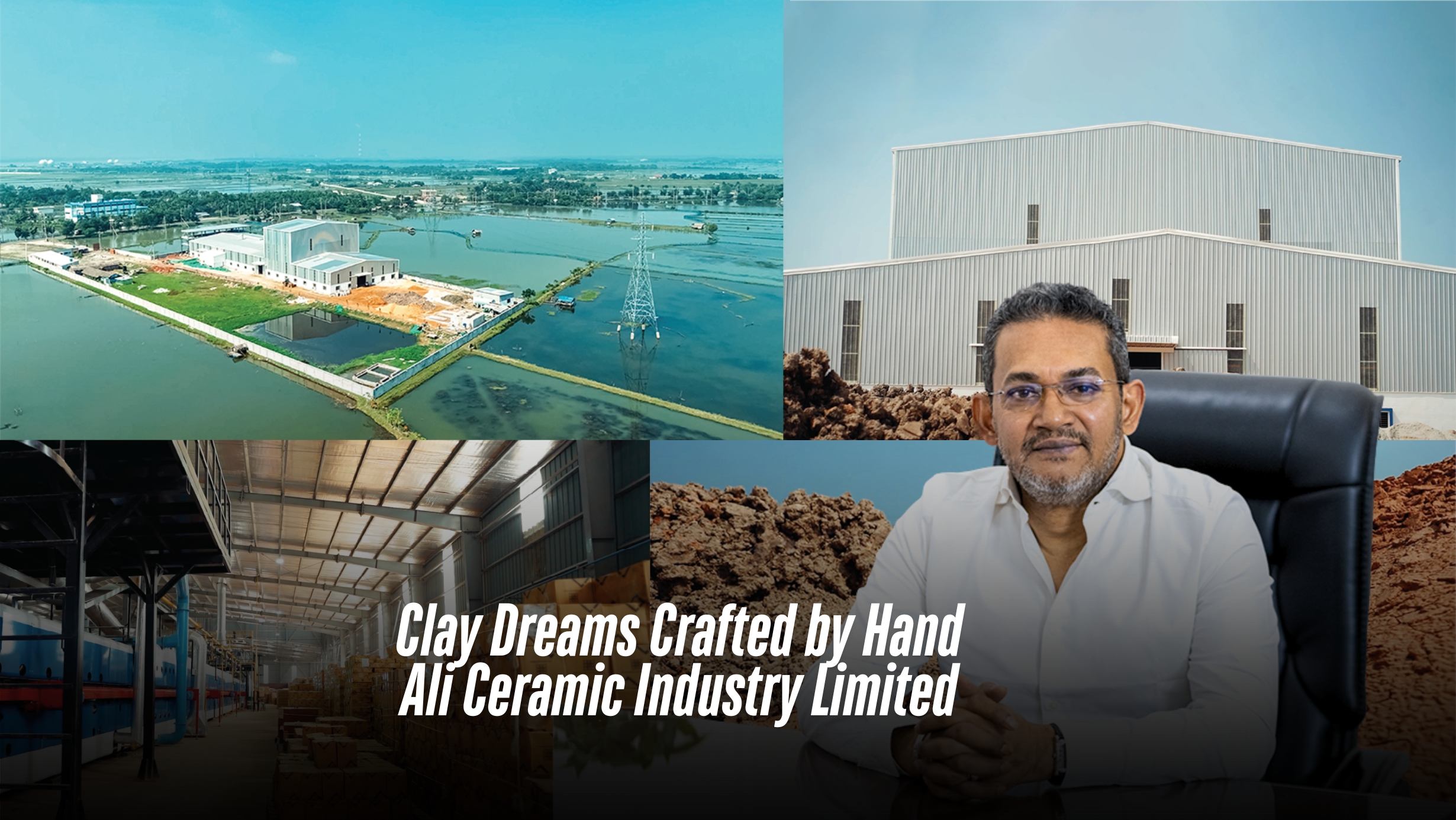

He added, “I have seen individuals get frustrated with their jobs if/when they get no opportunity to work on their competency. Once given the opportunity to explore, a working professional finds more interest in his work and solidifies into an asset for his company.” When asked about the hurdles of a career in this industry, Mr. Bashar recalled the tougher times and the ever-existing troubles. Having passed through them, he is now happy with where he stands and what he has learned through the experiences. He stated, “I am happy to have chosen this path for my career, considering that I was inclined towards doing what my friends did – going abroad for higher studies after graduation. Instead I joined DBL in 2007.” One of the most recent initiatives of the company is the Tiles manufacturing project in Sylhet.

The extension is called Bright Ceramics – a tiles, tableware and sanitary-ware manufacturing plant, which will finish construction by the end of next year. DBL is also working on advanced ceramic products. According to Mr. Bashar, among some of the major drawbacks of this industry is import dependency. The added disadvantages due to incremental gas price and shortage create a much greater impact on the production cost. A shortage of gas supply results in on-and-off gas in the kilns – slows down in production. According to Mr. Bashar, the added cost has only been inflicted on the manufacturers and the customers are unaffected. “The duty structure really surprised everyone. We are paying full duty on imported clay that is 25-30 per cent moisture.” Mr. Bashar pointed out. On a brighter note, DBL will be the first player in the subcontinent to incorporate Industry 4.0- allowing it to collect data analysed later on a big screen.

“The duty structure really surprised everyone. We are paying full duty on imported clay that is 25-30 per cent moisture.” Mr. Bashar pointed out. On a brighter note, DBL will be the first player in the subcontinent to incorporate Industry 4.0- allowing it to collect data analysed later on a big screen.

AI for DBL Ceramics DBL has already started with AI (artificial intelligence) for ceramics. It is planning on a full automation for the factory that will function with minimal human intervention. Mr. Bashar could only tell Ceramic Bangladesh Magazine that the AI software is being developed by an international IT company, and soon, will be set in motion.

Concerning imperatives Some of the current problems the company is facing in include:

- Due to gas price hike and shortage, DBL is reusing gas from the exhausts of Kiln and Generator.

- Even though production cost has gone up, it has kept the prices of the products stable.

- Due to a shortage of dollars, banks cannot open L/C, so the company is constantly innovating to find alternatives.

- Tiles is the last thing people buy and that’s usually when the budget is at its lowest, an impediment that directly affects the sales.

Difficulties with export “We have a huge demand for tiles in our local market so we are focused on catering to local customers, but we have exported to countries like Ethiopia and Canada,” Mr. Bashar mentioned. Export is quite difficult when the duty and freight costs are taken into account. The tableware sector has a higher potential for export compared to the tiles sector. DBL is trying to push products outside the country despite the competition and it is expected to grow in the export market.

Technical Porcelain, DBL’s signature product: Technical Porcelain has durability and can withstand dense traffic. This product has seen its rejections in the earlier days, but as people learned more about it, the sales have gone up foremost customers being architects and construction companies. Tiles with Sugar Effect have received acclamation from users’ as well. DBL ceramics is also the only company selling interlock tiles for walls. Out of the three, technical porcelain is the top selling tiles. Emphasising the initiatives of the company when it comes to sustainability, Mr. Bashar said, “We take our sustainability initiatives very seriously. We have been doing 100 percent water recycling since day one. We crush wasted tiles and reuse them in our recipe. We are also aiming to become 100 percent green within a year and a half.”

Technical Porcelain, DBL’s signature product: Technical Porcelain has durability and can withstand dense traffic. This product has seen its rejections in the earlier days, but as people learned more about it, the sales have gone up foremost customers being architects and construction companies. Tiles with Sugar Effect have received acclamation from users’ as well. DBL ceramics is also the only company selling interlock tiles for walls. Out of the three, technical porcelain is the top selling tiles. Emphasising the initiatives of the company when it comes to sustainability, Mr. Bashar said, “We take our sustainability initiatives very seriously. We have been doing 100 percent water recycling since day one. We crush wasted tiles and reuse them in our recipe. We are also aiming to become 100 percent green within a year and a half.”

Written by Chisty Rahim