CHARU Ceramics has offered a new choice for decorating bathrooms in Bangladesh. CHARU has been able to make the use of luxury bathroom

materialls easily possible go the mass people. Whereas it used to cost around Tk. 4,00,000 on an average earlier to build a luxurious bathroom, CHARU can supply the same quality of luxury products for Tk. 50,000 to Tk. 1,00,000 only. This is the great achievement of the Bangladeshi brand.

CHARU Ceramic Industries Limited was incorporated as a company in March 2012 and started its journey from 2017 by producing world-class sanitary ware in the country. It is the first international major standard sanitaryware manufacturing plant in Bangladesh with the assistance of the best consultants from Europe and Asia. This sanitary ware manufacturer, certified by ISO 9001:2015, has collaborated with COTTO, one of the most popular brands in the world. Some 1,800 skilled workers are working in the CHARU Sanitary ware factory established in Madhabpur, Habiganj.

The plant is equipped with state of the art technology such as robot glazing, high pressure casting, advance kiln and molder and the latest and advanced manufacturing machinery of sanitary wares from SACMI, UNIMAK and HEXIANG with production capacity of 1.5 million pieces a year.

Machineries of the world’s most renowned companies such as Gaiotto, Riedhammer and Unimak are installed to produce the best quality of sanitary ware in CHARU Ceramic Industry.

It is remarkable in the history of Bangladesh’s sanitaryware industry that CHARU manufactures one of the most internationally recognised sanitary ware brand ‘COTTO’ in Bangladesh with technical

collaboration of Siam Sanitary Ware Industry Co. Ltd., Thailand. COTTO is helping it to achieve the best quality by providing technological support, knowledge transferring and trained employees.

Currently, a wide range of water closet, wash basin, urinal and squat pan are produced by both the brands CHARU and COTTO – and these are manufactured in the country with utmost care and skills. CHARU ceramic wants to become the number one sanitary ware brand in Bangladesh with the finest products and efficient services.

CHARU Ceramic Industries Limited has been set up initially to fulfill the domestic market demand for products and then to export. Manufacturing products of higher standarcs, CHARU gives the customers with proper value and extreme durability of the products. The products have unique designs and it upgrades products range every year with hot designs. CHARU is manufacturing products using the latest technology. While showing internationally recognised innovativeness and proving technological ability, flexibility and adaptability, CHARU can meet the demand of mass production.

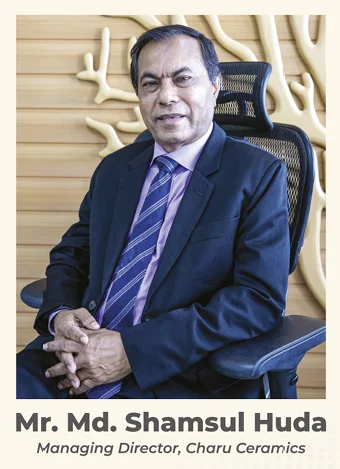

Interview with Managing Director

Quality, Design and Plumbing services are the main pillars of CHARU’s success

The name ‘Charu’ itself associates with the meaning of finesse. Although the local sanitary market in Bangladesh is still very young, the sector is growing rapidly, thanks to the growth of middle class, change in their taste and rapid urbanization process,” said Mohammad Shamsul Huda, Managing Director of CHARU Ceramics. He told Ceramic Bangladesh that the current market for sanitary ware in the country is in a range of Taka 1,000 crore to Taka 1,200 crore a year.

CHARU owns 20 per cent of the market share, he said and added that because of the construction boom, this market is growing at a rate of 15-20 per cent every year. The demand for sanitary products is increasing in the villagesas well. And thedemand for commodes is increasing in the cities, he pointed out.

The managing director mentioned that CHARU continues to compete with the imported foreign products of similar quality. However, CHARU is keeping an eye on the price so that it is more affordable than the imported products. Mr. Shamsul Huda said that although the annual production capacity of CHARU is 1.5 million pieces, its current production is 60 per cent of its capacity. It will increase to 80 per cent this year, he mentioned. However, production is also being affected due to the gas crisis.

Mr. Shamsul Huda has about 40 years of experience in the business of sanitary products in Bangladesh. He got involved with this business by setting up Bengal Agencies in the early 1980s. At first there was the business of mosaic, granite marble and white cement. From the import-dependent trading business, he gradually developed the Great Wall Ceramics Industry, CHARU Ceramics, Elephant Brand White Cement and Siam-Bangla Industries in the country.

the country.

The bathroom fittings industry will also start soon under the group, he said. In all cases it has retained the international standard and taste. As a result, there is a huge demand for these sanitary products at home and abroad. However, due to increase in domestic demand, it can’t meet the full demand of the domestic market. CHARU and Great Wall products are being exported to countries like the US, India, Pakistan and the countries of the Middle East. It is especially in high clemand in the ‘Seven Sister’ states of north-east India. Participating in fairs in Qatar, Pakistan and India, this Bangladeshi company has recently received huge response, the managing director said. Mega projects like Rooppur Nuclear Power Plant, Matarbari and Payra Power Plant, Karnaphuly Tunnel and Metro Rail in Bangladesh have received huge supplies of CHARU, COTTO and Great Wall products. Talking about the success and popularity of CHARU, Mohammad Shamsul Huda said that CHARU is working jointly with the COTTO brand of Thailand.

Dwelling on the shortage of designers in the sanitary ware industry, Mr. Shamsul Huda said that design is changing rapidly. “In order to increase exports, we have to create more diverse products and increase the number of designers in the country” he said. He added that to help brand Bangladesh’s own industry, the government should provide more assistance in this sector. “Number of ceramic institute should be increased. Emphasis should be given on finding world class designers by opening ceramic faculty in Art Colleges.”

Tejgaon Ceramic Institute in Dhaka is not enough to meet the demand of the time, he said, adding that only diploma engineers are produced here. So it needs to be upgraded as a university. At present: some engineers are coming out from BUET and Rajshahi, which is little compared to the demand. Since it has element of handicraft industry, skills and artistic knowledge are important here. And it takes at least five years to learn how to work perfectly in this sector. However, salary and other benefits of the manpower engaged in this sector is much higher.