The global ceramic industry, including Bangladesh, is navigating a period of uncertainty due to economic slowdowns, fuel shortages, and inflation. However, Paragon Ceramic Industries Limited (PCIL) has managed to stand out as a leader in this competitive sector, driven by an unwavering commitment to quality and resilience. Below is a closer look at the company’s journey, challenges, and future plans as discussed by its Managing Director, Farian Yusuf.

A Journey of Resilience and Early Success

Founded in June 2008, Paragon Ceramic began commercial production in December 2010. Remarkably, within just two months, the company achieved its first export, a significant milestone that set the stage for its future success. Despite the current oversupply in the domestic market, Paragon continues to thrive internationally, with exports showing considerable growth. “Our entry into exports soon after production was a major accomplishment,” said Yusuf. “Although the local market is challenging, we are seeing tremendous growth internationally.”

Paragon Ceramic: A Leader in High-Definition Porcelain Tableware Manufacturing

Located in Mirzapur, Gazipur, approximately 50 kilometers from Dhaka, Paragon Ceramic benefits from a strategic location with access to all necessary infrastructural facilities. With a total investment of over US$ 16 million, PCIL has established itself as a key player in the porcelain tableware industry in Bangladesh.

Cutting-Edge Technology and Skilled Workforce

PCIL specializes in manufacturing and exporting high-definition porcelain tableware, utilizing state-of-the-art machinery sourced from renowned global suppliers like SKK and TAKASAGO from Japan, TCK from Taiwan, Modena and COTO from China. The factory is supported by a workforce of approximately 1,600 highly skilled and motivated employees, ensuring the highest quality in every product.

“In a market where competition from China is fierce due to low pricing, Paragon Ceramic has adopted a strategy of prioritizing product quality over competing on price. China, with its advanced technology and domestic resource pool, offers products at far lower costs than Bangladesh.”

Durability and Performance

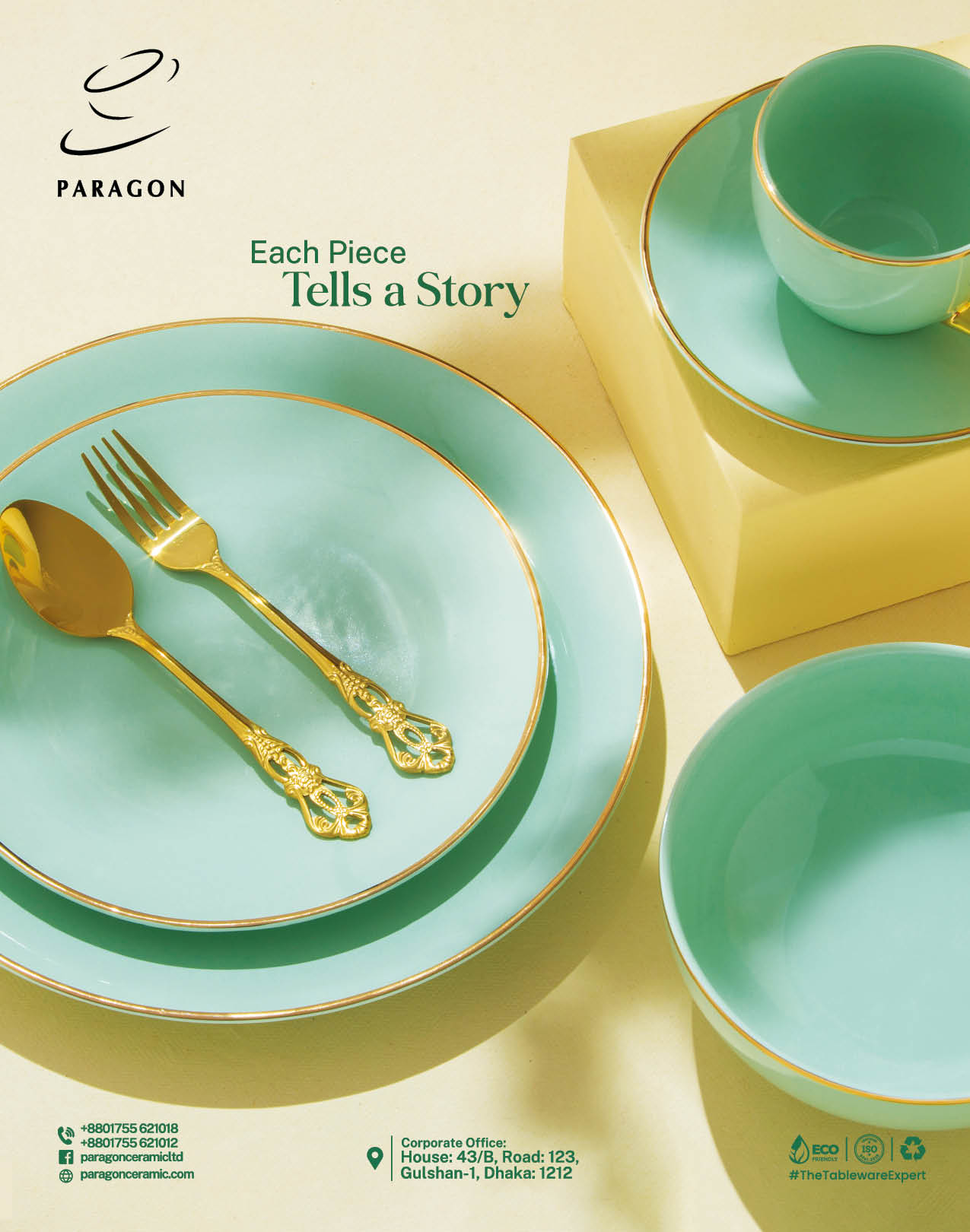

Paragon Ceramic decorated tableware combines vibrant colors and unique shapes that endure even the most demanding dining kitchens. Our proprietary clay recipe, infused with alumina, ensures strength, durability and a pure white finish. Yusuf said “Tested for quality, our products resist fading, chipping, and scratching, even after 500 dishwasher cycles. With advanced shape engineering and glazing techniques, we guarantee functionality, hygiene, and impact resistance”.

Innovation and Global Reach

Through cutting-edge technology and constant design innovation, Paragon Ceramic stays ahead of trends, offering high-performance tableware. With a robust global distribution network, we ensure timely deliveries worldwide.

State-of-the-Art Manufacturing and Quality Assurance

PCIL operates with cutting-edge technology, from its porcelain plant to its decal and packaging units. With modern equipment from Japan, Taiwan and China, and a highly skilled workforce, PCIL produces high-definition porcelain tableware for global markets like IKEA and H&M. The company excels in custom designs, meeting clients’ diverse requirements with unmatched flexibility and service.

Precision and Excellence in Every Step

PCIL’s advanced Mould unit and dedicated Quality Assurance (QA) team ensure every product meets strict international standards. With over 25,000 Mould produced monthly, the team delivers high-quality ceramics while adhering to ISO 9001:2015 standards for superior customer satisfaction.

Overcoming the Industry’s Biggest Challenges

Paragon has faced its fair share of challenges, from fuel shortages to a shortage of skilled workers. The company’s resilience in overcoming these hurdles speaks volumes. According to Yusuf, the biggest obstacle remains the gas crisis, which has severely impacted production costs and supply. “Fuel costs have skyrocketed by over 250 per cent, yet gas pressure remains very poor, affecting overall production,” he explained. “We’ve had to turn to alternative energy sources but that increases our costs, making us less competitive and facing global challenges to survive” Despite these difficulties, Paragon has continued to expand and evolve, focusing on maintaining its stronghold in international markets while also striving to meet local demand for Porcelain tableware.

Quality over Price:

A Global Strategy In a market where competition from China is fierce due to low pricing, Paragon Ceramic has adopted a strategy of prioritizing product quality over competing on price. China, with its advanced technology and domestic resource pool, offers products at far lower costs than Bangladesh. However, Paragon’s superior quality remains a competitive edge. “While China has access to its own resources, we rely heavily on imports, which raises our costs,” said Yusuf. “But in terms of quality, we’re second to none and that’s what has helped us to secure buyers internationally.”

Reducing Import Duties:

A Key to Growth Yusuf believes that reducing import duties on raw materials could significantly boost Bangladesh’s Ceramic industry and its global competitiveness. Since the sector relies entirely on imported raw materials, lowering these costs could fast-track growth and innovation. “If the government offers duty benefits, the sector will see accelerated development. We have the potential, but policy support is crucial to our future,” said Yusuf.

Attracting Foreign Direct Investment (FDI) for Expansion

Paragon Ceramic is also focused on attracting foreign direct investment (FDI), which Yusuf sees as essential for broadening the scope of the industry. More FDI could increase the number of companies in the sector, giving buyers more options and boosting confidence in Bangladeshi ceramics. “In the same way that Bangladesh’s garment industry grew with increased foreign investment, the ceramic sector can also be benefited,” Yusuf explained. “The more companies we have, the more options buyers have, leading to better overall industry growth.”

The Gas Crisis: A Major Production Bottleneck

The ongoing gas crisis has led to a surge in fuel prices and decreased availability, creating a substantial challenge for Paragon and other industries. Low gas pressure in industrial areas like Gazipur has severely impacted production as well as quality that reflects on financial statement. “The entire industrial area is affected by this, and it’s not just us—garment and other industries are also facing disruptions,” Yusuf said. “We need long-term solutions for energy security if we are to continue growing.”

Technological Advancements: A Path Forward

Yusuf emphasizes the need for technological innovation to enhance production efficiency and maintain competitiveness. While inflation has dampened local demand for ceramic products, advancing technology could help minimize losses and improve overall output. “We are behind in technology,” he admitted. “If we focus on energy security and workforce training, we can boost our output and improve the industry’s future.”