Author: admin

Spotlight Artisan Ceramics at the forefront (04)

Amongst the Royal collection in the Buckingham Palace resides gold-covered renditions of Artisan Ceramics. From a company struggling to export, to winning the national export trophy five times in a row, Artisan Ceramics has seen 3 times expansion over the past few years. The entirety of a company’s growth and success inevitably relies on the decisions made internally. Artisan Ceramics Ltd. suffered significant loss until 2011. With new leadership under Finlays, and a change in the modality of business and redesigning, it now has a factory constructed across six acres of land in Sreepur, Gazipur, and a capacity of producing 10 million pieces of assorted premium quality porcelain tableware annually. The current expansion will raise this capacity to 22 million. Artisan Ceramics is an export-oriented tableware company that supplies to over 20 countries across Europe, America, and Asia, and has evolved into a leading manufacturer with no stop to its growth. The company has a contribution of 12-15 percent in the national export revenue. Surely, success in such a short time is a wonder on its own. To find out more, Ceramic Bangladesh Magazine author recently had the opportunity to discuss the adaptations of Artisan Ceramics that led to its success, with M. Mamunur Rashid, CEO of Artisan Ceramics Ltd. Here’s what we’ve learned: The first adaptation Artisan knew Saggar firing was wasteful Saggar or Saguaro is a covering used over ceramic ware when under intensive firing in the kilns. This protection helps safeguard the ware from coming in direct contact with the Kiln, debris inside the kiln, and other gases and smoke. The problem with saggar firing is that the saggar heats up first and then transfers the heat to the product; this makes the process 15-hour long cycle. With Artisan’s adaptation, open and fast firing, it’s a six-hour firing process. “Time-wise and price-wise, Saggar is inefficient. Again, there is the cost of the man behind the machine,” says Mr. Rashid. Fired three times for a longer life! “I have traveled across more than 10 countries just to see the technology companies have adopted, and learned, that the type of products we tend to manufacture are widely unavailable,” said Mr. Rashid. “We have products that have been fired three times, which make them much more durable. These products are more popular in Europe since they are more durable and can withstand knives and forks,” he added. At Artisan, products are fired at high degrees of temperatures — 1330°C to 1350°C, about 100° higher than the global rivals. Discussing global demand with relevance to this particular firing process, we find: “The hard glaze we are using, makes the product stronger, more scratch-proof, and absorption free,” said Mr. Rashid. The global demand has shifted towards such products because of such features. Raw materials sourced from around the world Artisan Ceramics sources its raw materials from almost every corner of the globe –the UK, Germany, Italy, New Zealand, Vietnam, Japan, China, and India are some of them. The two types of minerals that make up for 50% of the body, feldspar, and quartz, are brought in from Rajasthan, India. The company also imports alumina which is used to make the body stronger and helps meet HoReCa standards. “Using the best quality raw material with a natural colour is important because the glaze is translucent and the body colour is what you see,” he said. These designs are in trend now and a personal favourite of Mr. Rashid. The company even imports from specific mines. Furthermore, Artisan buys the best quality gold from Heraeus Germany and colors from Izawa Pigments, Japan. Innovative Designs that go well with the trend, and the technology behind it. Artisan is constantly working on new designs. “We are innovating and have recently created double-layer body tea cup that keeps tea & coffee warm for a longer period of time,” Mr. Rashid mentioned. The design depends on customer trends and comes in cyclic order, says Mr. Rashid. Something that is currently trending are reactive glazes where you allow the finishing to be exactly how the kilns are making them fascinate many people. “Keeping up with the ever-evolving trends is a constant challenge, but traditional designs have resurfaced and are a popular preference now,” said Mr. Rashid. Artisan will be introducing a certain collection inspired by the Rajasthani culture. A designer from Sri Lanka by the name of Sudath Fernando is also coming in to train employees. Stay tuned with us for future features. Regarding technology, he said: “We want to make our factory fuel efficient. Our dryers are like ovens that collect heat and reuse it. I have visited a few factories in Europe and have seen how they are doing things, we have called SACMI, Italy, to help us upgrade.” The machines at Artisan’s factory are from the USA, the UK, Japan, Taiwan, and China. Artisan has taken green initiatives- they refine and reuse 90% of wastewater, collect rainwater in underground tanks, and reuse heat from the ovens. The company purifies water to the extent that it can be used for irrigation. “Every factory is concerned and the government is putting emphasis on sustainable approaches,” stated Mr. Rashid. Artisan’s plan to sell in bulk Following the recent expansion, Artisan is now concentrating on bulk buyers- examples would be hypermarkets. The marketing team is also trying to bring about a trend change by promoting the use of porcelain over bone china. This is because the water absorption of Bone China is high, it loses colour, and porcelain survives longer. Ultra Bone Porcelain: the newest innovation from Artisan Some customers are price-centric and some look for quality. That is why Artisan needed to innovate a new product retaining the same mechanical strength of pure porcelain and exceptional whiteness that was sure to win people over. Henceforth, came the Ultra Bone Porcelain. Mr. Rashid introduced a special body that can beat the competition and customers are willing to pay premium price for it. Artisan performs CSR Artisan gives education

Read More

Artisan Ceramics at the forefront

Amongst the Royal collection in the Buckingham Palace resides gold-covered renditions of Artisan Ceramics. From a company struggling to export, to winning the national export trophy five times in a row, Artisan Ceramics has seen 3 times expansion over the past few years. The entirety of a company’s growth and success inevitably relies on the decisions made internally. Artisan Ceramics Ltd. suffered significant loss until 2011. With new leadership under Finlays, and a change in the modality of business and redesigning, it now has a factory constructed across six acres of land in Sreepur, Gazipur, and a capacity of producing 10 million pieces of assorted premium quality porcelain tableware annually. The current expansion will raise this capacity to 22 million. Artisan Ceramics is an export-oriented tableware company that supplies to over 20 countries across Europe, America, and Asia, and has evolved into a leading manufacturer with no stop to its growth. The company has a contribution of 12-15 percent in the national export revenue. Surely, success in such a short time is a wonder on its own. To find out more, Ceramic Bangladesh Magazine author recently had the opportunity to discuss the adaptations of Artisan Ceramics that led to its success, with M. Mamunur Rashid, CEO of Artisan Ceramics Ltd. Here’s what we’ve learned: The first adaptation Artisan knew Saggar firing was wasteful Saggar or Saguaro is a covering used over ceramic ware when under intensive firing in the kilns. This protection helps safeguard the ware from coming in direct contact with the Kiln, debris inside the kiln, and other gases and smoke. The problem with saggar firing is that the saggar heats up first and then transfers the heat to the product; this makes the process 15-hour long cycle. With Artisan’s adaptation, open and fast firing, it’s a six-hour firing process. “Time-wise and price-wise, Saggar is inefficient. Again, there is the cost of the man behind the machine,” says Mr. Rashid. Fired three times for a longer life! “I have traveled across more than 10 countries just to see the technology companies have adopted, and learned, that the type of products we tend to manufacture are widely unavailable,” said Mr. Rashid. “We have products that have been fired three times, which make them much more durable. These products are more popular in Europe since they are more durable and can withstand knives and forks,” he added. At Artisan, products are fired at high degrees of temperatures — 1330°C to 1350°C, about 100° higher than the global rivals. Discussing global demand with relevance to this particular firing process, we find: “The hard glaze we are using, makes the product stronger, more scratch-proof, and absorption free,” said Mr. Rashid. The global demand has shifted towards such products because of such features. Raw materials sourced from around the world Artisan Ceramics sources its raw materials from almost every corner of the globe –the UK, Germany, Italy, New Zealand, Vietnam, Japan, China, and India are some of them. The two types of minerals that make up for 50% of the body, feldspar, and quartz, are brought in from Rajasthan, India. The company also imports alumina which is used to make the body stronger and helps meet HoReCa standards. “Using the best quality raw material with a natural colour is important because the glaze is translucent and the body colour is what you see,” he said. These designs are in trend now and a personal favourite of Mr. Rashid. The company even imports from specific mines. Furthermore, Artisan buys the best quality gold from Heraeus Germany and colors from Izawa Pigments, Japan. Innovative Designs that go well with the trend, and the technology behind it. Artisan is constantly working on new designs. “We are innovating and have recently created double-layer body tea cup that keeps tea & coffee warm for a longer period of time,” Mr. Rashid mentioned. The design depends on customer trends and comes in cyclic order, says Mr. Rashid. Something that is currently trending are reactive glazes where you allow the finishing to be exactly how the kilns are making them fascinate many people. “Keeping up with the ever-evolving trends is a constant challenge, but traditional designs have resurfaced and are a popular preference now,” said Mr. Rashid. Artisan will be introducing a certain collection inspired by the Rajasthani culture. A designer from Sri Lanka by the name of Sudath Fernando is also coming in to train employees. Stay tuned with us for future features. Regarding technology, he said: “We want to make our factory fuel efficient. Our dryers are like ovens that collect heat and reuse it. I have visited a few factories in Europe and have seen how they are doing things, we have called SACMI, Italy, to help us upgrade.” The machines at Artisan’s factory are from the USA, the UK, Japan, Taiwan, and China. Artisan has taken green initiatives- they refine and reuse 90% of wastewater, collect rainwater in underground tanks, and reuse heat from the ovens. The company purifies water to the extent that it can be used for irrigation. “Every factory is concerned and the government is putting emphasis on sustainable approaches,” stated Mr. Rashid. Artisan’s plan to sell in bulk Following the recent expansion, Artisan is now concentrating on bulk buyers- examples would be hypermarkets. The marketing team is also trying to bring about a trend change by promoting the use of porcelain over bone china. This is because the water absorption of Bone China is high, it loses colour, and porcelain survives longer. Ultra Bone Porcelain: the newest innovation from Artisan Some customers are price-centric and some look for quality. That is why Artisan needed to innovate a new product retaining the same mechanical strength of pure porcelain and exceptional whiteness that was sure to win people over. Henceforth, came the Ultra Bone Porcelain. Mr. Rashid introduced a special body that can beat the competition and customers are willing to pay premium price for it. Artisan performs CSR Artisan gives education

Read More

Smart Fire Safety is a must for SMART BANGLADESH

A three-day 9th International Fire Safety and Security Exhibition-2024 concluded with a focus on bolstering Bangladesh’s fire safety measures and aims to reduce fire risks, utilise modern equipment for safety, and raise awareness among the mass people. In the expo held on February 17-19, the people engaged in the industry underscored the need for amending the Bangladesh National Building Code (BNBC) 2020 as part of ensuring preventive measure of fire incidents and maintaining fire safety compliance in factories, housing and public infrastructure including mega projects. Held at the Bangabandhu International Conference Centre (BICC) in Dhaka, the expo was organised by Electronics Safety and Security Association of Bangladesh (ESSAB) in association with Bangladesh Fire Service and Civil Defence (BFSCD), Fire Fighting Equipment Business Owners Association of Bangladesh (FEBOAB), Federation of Bangladesh Chambers of Commerce and Industries (FBCCI), Bangladesh Garment Manufacturers and Exporters Association (BGMEA), Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), Bangladesh Textile Mills Association (BTMA), Dhaka North and South City Corporations, the Ministry of Commerce, and the Ministry of Home Affairs. More than 100 organisations from 30 countries including the USA, the UK, EU, China, India, the United Arab Emirates, and other Middle East countries took part in the expo. And more than 15,000 local and foreign visitors visited the expo. Salman F. Rahman, Private Industry and Investment Adviser to the Prime Minister, inaugurated the expo on February 17 while Fire Service and Civil Defence Director Brigadier General Mohammad Main Uddin, FBCCI President Mahbubul Alam and BGMEA President Faruque Hassan were present, among others. Brig. Gen. Main Uddin informed a seminar during the expo that the Fire Service and Civil Defence (FSCD) received 22,300 fire incidents per year but last year it was increased to 28,703 while on an average 150 deaths are recorded every year. In these incidents, an average loss was Tk 368 crore each year and the loss amounted to around Tk 793 crore last year. About 36 per cent fire incidents was caused by electricity last year, he added. Architect Iqbal Habib said using technology harnessing data from every level is a must to monitor and manage city infrastructure to build smart city and provide facilities to citizens. He also said if the soft copy of the building design is on the device, it will reach the fire fighters at the premises within a second. The PPP model will ensure smart safety and security solution to make sure that fire incident would not take place. Investment required for boosting the industry: With the expansion of industrialisation, the demand for fire safety and security equipment is rapidly growing in Bangladesh. But the country is still highly dependent on imported products. Industry insiders say Bangladesh has to depend on around 95 per cent import of the products. So, the country has a scope of attracting a huge investment, and also export the products meeting domestic demand for around Tk 15,000 crore market, if investors get adequate policy support from the government. ESSAB Safety Excellence Award 2024: A total of 13 organisations have been awarded at the expo for ensuring building code compliance and fire safety measures in residential, industrial, commercial buildings. Among them, Rancon Artisti Residences stood first in the residential building category, while Sheltech Rubynur stood second, and Concord Shapla third. In the Commercial Building Category, Shanta Forum, Concord MK Heritage and BGMEA Complex received the award as the First, Runner-Up and Second Runner-Up. Six companies jointly won the excellence award in the Industrial (RMG) category. Among them, Glamour Dresses Ltd. and Designtex Knitwear Ltd. were named the top winners. Tasniah Fabrics Ltd. and SQ Birichina Ltd. came next, followed by Sterling Denims Ltd. and Silken Sewing Ltd. Besides, BM Container Depot Ltd. received the award in the industrial other category. ESSAB also gave special recognition to five fire service personnel for their brave role in fire fighting and rescue operations. They are Deputy Assistant Director of Fire Service and Civil Defence Department Md. Faisalur Rahman and Mohammad Safiqul Islam, Senior Station Officer Md. Nazim Uddin Sarkar, Warehouse Inspector Md. Zahirul Islam and Fire Fighter Alhaj Miah. PPP required to explore untapped market: ESSAB: The ESSAB Secretary General, Zakir Uddin Ahmed, said the sector is important to protect people’s lives and properties from fire and earthquake incidents, and ensure sustainable economic development. So, what are needed include significant awareness, regular checks of the fire safety equipment, and use of quality materials. Mr. Zakir, also Chief Executive Officer of ZM International, stated that PPP is required to explore the untapped market. “We are ready to help investors here. So, policy assistance is the main issue to bring more investment. To create awareness, he fires safety issue should be included in textbooks,” he said adding that high import duty on the products is a key challenge in the industry. In this context, the government should provide all necessary facilities such as policy support, duty cut, and incentive so that investors come to invest in the sector.

Read More

Of Verdant Backdrop Red Brick Surface and A Memorial Of Pride

Architecture, in its own language, has the power to narrate stories, forge distinctive perspectives, and evoke profound emotions. The National Martyrs’ Memorial in Savar is one of those powerful architectures that bear the history and bravery of the nation with its grandeur and glory. Located in Savar, an industrial hub on the outskirts of Dhaka, the monument stands tall as an emblem of reverence, embodying the nation’s profound gratitude to those brave souls who made the ultimate sacrifice in the pursuit of self-determination for the Bengali people. After taking a short tour around it, visitors can’t help but feel a sense of awe and pride as they contemplate the nation’s immense history and resilience. The vast landscape, the luscious greenery surrounding it, and the soaring height of the establishment will remind of its relative insignificance in the grand scheme of things. The month of March in Bangladesh is a time of remembrance and reflection. For millions of Bangladeshis, Independence Day is a day of extraordinary sentiments, containing both happiness and grief as the country earned its sovereignty 54 years ago at the cost of 3 million lives. Three phases of construction: The National Martyrs’ Memorial is designed by architect Syed Mainul Hossain (1952-2014). With a distinguished jury, including architect Muzharul Islam, a national design competition for the monument took place in 1978. (The previous attempt didn’t yield any satisfactory results.) Among 57 contenders, the young 26-year-old architect Mainul emerged victorious with his standout design. The inception of the project dates back to 1972, marking the acquisition of approximately 110 acres by the government. Of this expanse, 84 acres were dedicated to the construction of the main complex, while the remaining land was set aside for a verdant land-water greenbelt. The initial phase saw the creation of access roads, laying the foundation for subsequent development. In the second phase spanning from 1974 to 1982, significant infrastructural elements such as mass graves, helipads, parking facilities, and pavements were meticulously established. Finally, the third phase in 1982 witnessed the realisation of the main monument, along with the establishment of the greenbelt and a cafeteria, concluding the completion of this national monumental endeavour. The main monument was built by Concord in 1982 in only 89 days. In 1988, architect Syed Mainul Hossain received the Ekushey Padak, one of the highest civilian honours of the country, in recognition of his profound contribution to Bangladesh’s cultural heritage. A sneak peek into this architectural marvel: The central structure of the National Martyrs’ Memorial comprises seven pairs of triangular shapes, each representing pivotal events that propelled Bangladesh towards its independence. Starting with the outermost and shortest triangle, the structures progressively increase in height, leading up to the innermost peak. This architectural metaphor symbolises the nation’s ascent despite formidable challenges. The monument is made of concrete, in contrast with the rest of the structures and pavements, which are made of red bricks. Its design offers a multifaceted viewing experience, presenting a symmetrical pyramid-like formation when observed from afar. However, closer inspection reveals a dynamic interplay of angles and perspectives, inviting visitors to explore its intricate details firsthand. Notably, the surface of the structure is intentionally uneven, mirroring the tumultuous journey towards freedom and independence. This tactile representation serves as a poignant reminder of the sacrifices made and the resilience required to overcome adversity. The whole campus is adorned with trees, walkways, an artificial lake, and a cafeteria. Interplay of numbers: Numerology serves as a hidden vital factor behind the intricate design of the National Monument, reminiscent of ancient architectural wonders like the Athenian Parthenon, where numbers were revered as the essence of aesthetic perfection and cosmic harmony. At the heart of this establishment lies the mystical number 7, symbolising the seven pivotal movements that shaped Bangladesh’s path to independence between 1952 and 1971. The first of these 7 historical contexts is the language movement of 1952. This was followed by the United Front elections of 1954, the Constitution Movement of 1956, the Education Movement of 1962, the Six-Point Movement of 1966, the People’s Uprising of 1969, and then the final victory through the Great Liberation War of 1971. However, these 7 pillars or the number 7 also have different implications if we look at them from different facets. For example, among others, the Language Movement in 1952 contains 5+2=7; December 16, the day of independence in 1971, has 1+6=7; and there were 7 Birsreshto (war heroes) who sacrificed their lives for the cause of liberation. Written Kaniz F. Supriya

Read More

A Historical Breakthrough in Ceramic Industry!

China’s ceramic industry has achieved a historic milestone in the goal of carbon neutrality. After nearly one year’s hard research work, the world’s first piece of ceramic tile fired with zero-carbon fuel was successfully produced in Oceano Test Center, giving a great technological support to the building ceramic industry in realising the target of Carbon Peak and Carbon Neutral. It was announced at a press conference in Foshan Xianhu Lab on December 23, 2022, the world’s first piece of ceramic tile f ired with zero-carbon pure ammonia fuel has successfully exited the Ammonia-fueled Roller Kiln at Oceano Test Center. The Associated R&D Center on Advanced Zero-carbon Combustion Technology was jointly established by Foshan Xianhu Lab, Oceano Ceramics and DLT Technology on December 27, 2021. HLT & DLT are the world’s leading suppliers of complete plant equipment for the ceramic sector. To provide turnkey project solutions to the global ceramic industry, Foshan HLT DLT Technology has been the first tunnel kiln that integrated green, low-carbon, and intelligent automation for the Chinese ceramic machinery industry to enter. Headed by Academician Mr. Cheng Yibing, a strategic scientist working at Foshan Xianhu Lab, as Chief Director of the center, the lab was aiming at the key technology of zero-carbon combustion in ceramic kilns to explore new solutions for Chinese ceramic industry. By giving full play to the advantages of the three parties in terms of production, developing and research, the center has developed the “ammonia-hydrogen fusion zero-carbon combustion technology” as well as key systems and solutions for the industrialisation. The center has developed a new series of pure ammonia type and natural gas – ammonia mixture type industrial burners with related auxiliary technologies, having realised stable ignitions in DLT industrial experiment kiln fueled with mixed ammonia and pure ammonia, showing good control of nitrogen oxides emission in compliance with the national standards. This achievement has confirmed for the first time the practical feasibility for the ceramic industry to achieve carbon peak and carbon neutral technology’s industrialisation in the future, marking an important milestone for the industry. The f iring of ceramics with zero-carbon fuel is a disruptive technical innovation, having filled up blanks of both domestic and international, showing a new energy technological path for the ceramic industry as well as for the whole of building material industry to achieve carbon peak and carbon neutral goal with great practical significance. While developing the zero-carbon combustion technology, the team also established a set of safety system and emergency management measures suitable for ammonia-fueled ceramic kilns, including operating procedures, ammonia storage, transportation and other important aspects. Based on this, the team successfully completed the update of Oceano’s ceramic roller kiln by converting the kiln from natural gas fueled mode into pure ammonia and natural gas – ammonia mixture fueled mode. Moreover, it has also developed a precision control system for liquid ammonia evaporation and supply, which is monitoring system for residual ammonia in the fume, and has jointly developed a complete set of high-efficiency liquid ammonia SCR de-nitrification system as well as other technologies and equipment. suitable for the pure ammonia combustion, an online On December 18, 2022, the kiln fueled with 100% ammonia (NH3) successfully produced glazed and unglazed tiles with continuous tile feeding and production. Tested by Oceano Research & Development Center, the quality of finished tiles is above the national standard. According to the on-site test by a third-party environmental assessment agency, the exhausted fume emission of the kiln complies to the national standard. As the first thermal equipment manufacturer to participate in the research and development of Ammonia-Hydrogen Zero-Carbon Combustion Advanced Technology, DLT has been focusing on the energy saving and emission reduction of kilns and dryers for the ceramic industry, and has been contributing greatly to the industry’s carbon consumption reduction in order to undertake its social responsibility. In future, the Associated R&D Center on Advanced Zero-carbon Combustion Technology will be further utilised in the application of mass production in the industry on the basis of the results from this pilot production, and will keep breaking through and optimising the new technology adapting with mass production, as a contribution to the ceramic industry as well as the building material industry to achieve the goal of carbon peak and carbon neutral, in order to create a disruptive technological path leading from “0” into “1” as being the first time in the world. Project Initiation: Ammonia-Hydrogen Zero-Carbon Combustion Tech When the zero carbon combustion chemical equation appeared on the screen of the launch ceremony, it marked a significant breakthrough in carbon neutrality technology. On December 28, the “Advanced Ammonia-Hydrogen Zero-Carbon Combustion Technology Demonstration Project for Ceramic Slab and Tile Mass Production Line” (“Ammonia Hydrogen Zero Carbon Combustion Project”) was officially launched at the headquarters of Monalisa Group. This is a new path explored by Monalisa in collaboration with Foshan Xianhu Laboratory, DLT, Oceano, Guangdong Anqing Technology and other companies to build ceramic zero carbon manufacturing and green development, which marks a major step forward for the industrial application of carbon-neutral technology in China’s ceramics industry, and is of great significance for accelerating the green and low-carbon transformation and development of the industry. Ammonia-hydrogen Zero-Carbon combustion technology to explore the optimal solution for the path of carbon neutrality and emission peak. With the current carbon neutrality and emission peak strategy, hydrogen energy and ammonia energy, as renewable green energy sources with high energy density, good storage and transportation convenience, clean and efficient energy, have gradually become an important part of the future energy system and are energy terminals. At present, the ammonia-hydrogen zero-carbon combustion technology has successfully completed technical tests and demonstration production in the Oceano’s experimental kiln. In order to promote the industrial application of ammonia hydrogen zero carbon combustion technology, Monalisa has joined the industrialisation research project of this technology and launched the demonstration project. Based on the developed advanced ammonia hydrogen zero carbon combustion pilot test and pollutant emission detection and control pilot test, the advanced ammonia hydrogen zero carbon

Read More

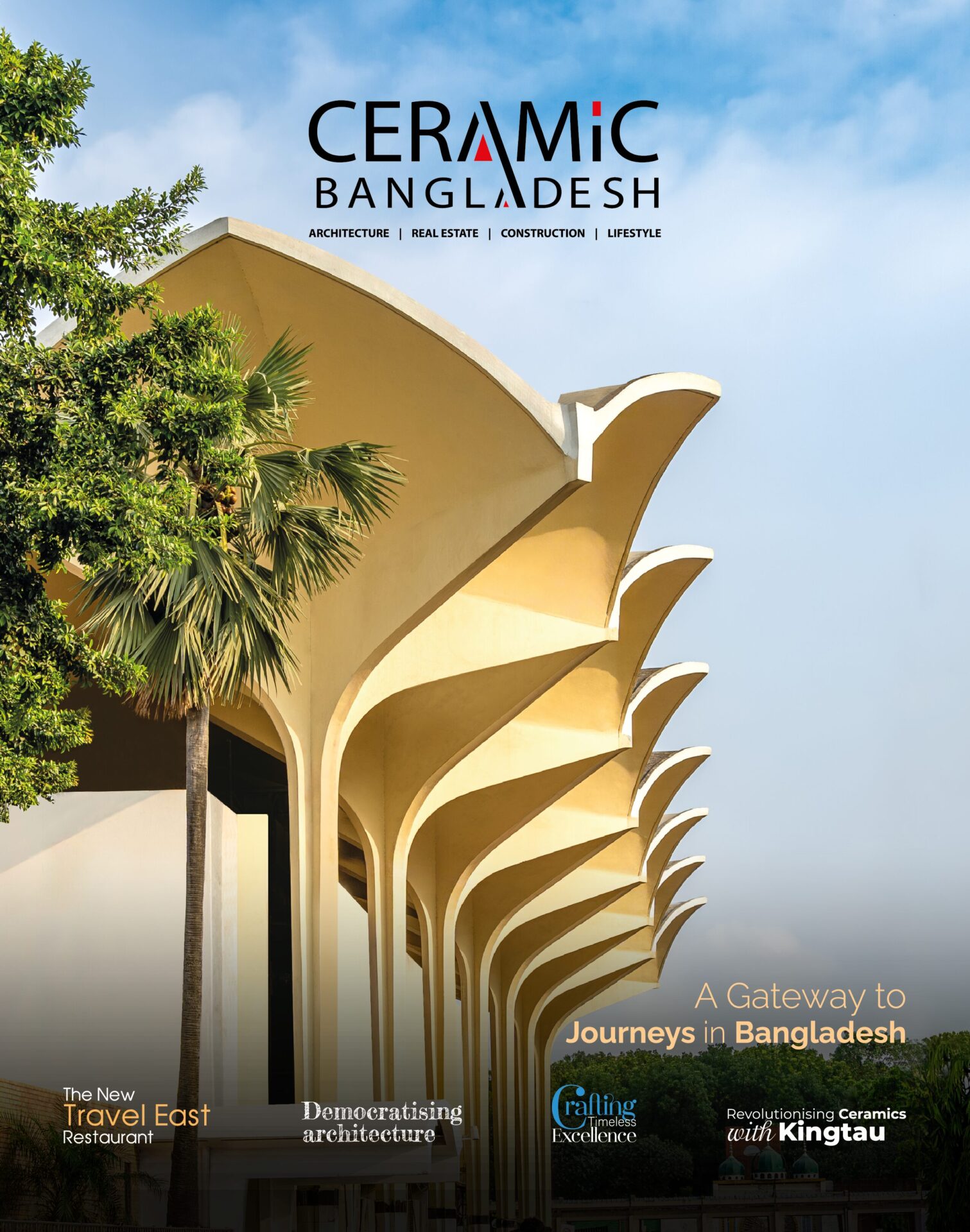

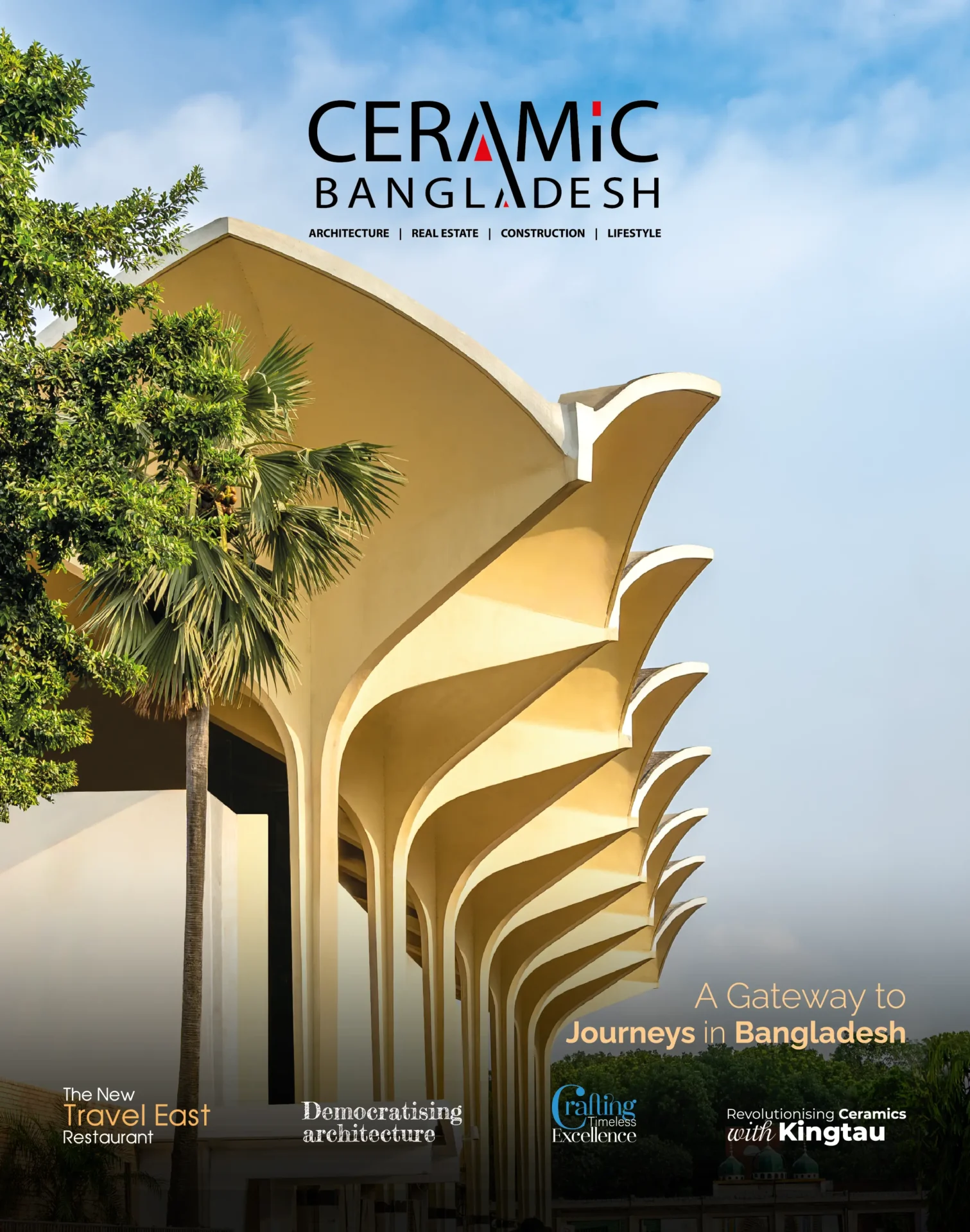

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far. Its rich history, architectural significance, and constant activity make it an iconic landmark. With a unique design and historical roots, Kamalapur Railway Station weaves together the fabric of Bangladesh’s rail network. The station’s significance has increased following the opening of the Padma Bridge. Kamalapur Railway Station (KRS), steeped in history, stands as Dhaka’s historic gateway. Its iron-clad colonial-era architecture evokes memories of a bygone era, a bridge between past and present. But Kamalapur is more than just a transit point; it embodies the spirit of a nation on the move—a pulsating heartbeat that reverberates across Bangladesh. Kamalapur Railway Station stands as a vital link in Bangladesh’s transportation network, connecting people, cultures, and commerce. As trains arrive and depart, the passengers weave intricate stories etched into the very walls of this magnificent station. Here, hope mingles with anticipation, dreams find their rhythm, and reunions unfold. The station’s bustling platforms witness resilience—the quiet strength of travellers forging ahead despite life’s twists and turns. And within its echoing halls, new beginnings take root, fueled by the promise of distant horizons. Kamalapur Railway Station, standing tall against the passage of time, is a living testament to Bangladesh’s architectural ingenuity. It’s not merely a physical structure; it’s a gateway to aspirations, connections, and the beating heart of a nation. As passengers step onto its platforms, they become part of a grand narrative—a journey that transcends mere destinations and becomes an enduring legacy of rail travel in Bangladesh. Architectural Marvel Kamalapur Railway Station stands as a captivating blend of modernity and tradition. More than a mere transportation hub, it represents an architectural marvel that seamlessly connects the past with the present. Designed by the renowned American architects Daniel Dunham and Robert Boughey (Bob Buie) of Louis Berger and Consulting Engineers Ltd. in the 1960s, Kamalapur Railway Station serves as a symbolic gateway to Dhaka. Daniel Dunham, a young architect fresh from completing his studies at Harvard’s Graduate School of Design (GSD), took charge of Berger’s fledgling Dhaka office. His task was to tackle an extensive backlog of new projects. The station’s architecture draws inspiration from both modernist principles and traditional neo-Islamic influences, as well as Bengali styles. It stands as a testament to Dhaka’s modern architectural spirit. Architect Daniel Dunham skillfully blended modernist elements with traditional Bangladeshi architecture. The station’s most striking feature is its parabolic shell roof—a true engineering masterpiece. Stretching over the platforms, this roof provides shelter to passengers. The lattice-like concrete structure fosters openness and allows natural light to filter through, creating a welcoming ambiance. Kamalapur Railway Station officially opened on May 1, 1968, during President Ayub Khan’s tenure. Its construction cost at the time was Taka 5 crores 30 lakh. When the value of one vori of gold stood at only 100 takas, A year after its inauguration, the Provincial Office of the Railway Postal Service found its new home within this remarkable station building. Design Features The station building is well-suited for tropical climates, providing protection from rainwater like an umbrella. It incorporates various functional spaces, including ticket booths, administrative offices, passenger lounges, waiting areas, and restrooms, all under an integrated canopy-based roof. The structure comprises 36 square domes supported by a total of 49 columns. Above these columns stands a roof featuring 36 slender concrete umbrella-type domes. Each column extends 59 feet high, branching out to support the roof. The open-air design capitalises on Dhaka’s cross breezes while safeguarding interior spaces from monsoon rains. The Kamlapur Railway Station’s thin concrete shell dome-umbrella design, completed by the consultants, has become a local icon, cherished by prominent architects as a cultural heritage piece. The parasol roof continues to define the station’s unique skyline. Architect Dunham immersed himself in Bangladeshi culture, learning Bengali and adapting to local craftsmanship and construction practices. Instead of designing an enclosed monolithic structure with mechanical heating and cooling systems, Dunham leveraged Dhaka’s tropical climate. His innovative roof system provides shade over the station’s offices and facilities, supported by a versatile field of columns. The construction technique involves thin concrete shells, which Dunham explored during his thesis at the GSD. After Dunham’s departure, architect Robert Boughey took over the post, designing tessellating concrete shells for the roof, reminiscent of pointed arches seen in Islamic architecture. These shells were cast on-site using reusable materials. Kamalapur Railway Station, with its remarkable parabolic shell roof, stands as an engineering marvel. This expansive structure spans the platforms, providing shelter to passengers. The station’s circular layout, boasting a diameter of 186 metres, centres around a soaring dome that reaches a height of 26 meters. Eight radial wings extend from the central hub, housing platforms, and tracks. The station’s architecture seamlessly blends modernist elements with traditional Bangladeshi motifs, reflecting the nation’s spirit. The concrete lattice structure allows natural light to filter through, creating an airy and open ambiance. High ceilings and spacious interiors enhance the feeling of grandeur. Kamalapur’s design prioritises functionality while maintaining aesthetic appeal. Geometric patterns, arches, and intricate details evoke the essence of Bengali culture. As a testament to Bangladesh’s identity and heritage, Kamalapur Railway Station stands proudly. The station is an engineering marvel that spans the platforms, providing shelter to passengers. Additionally, in other parts of the country, the Sylhet Railway Station in the north-eastern region and the Chilahati International Rail Station in the north-western part also feature a similar umbrella-like structure. These stations use national flower-shaped “shapla” shells supported by a forest of columns to cover their facilities. Historical Context Bangladesh Railway has been operating in the British period since 1862 in the eastern and western parts of the country, divided by the great river

Read More

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far.

Read More

Democratising architecture: Design that inspires awe and closeness to home

It was as though the beauty, heritage, and history of Mymensingh were plotting the becoming of Architect Masudur Rahman Khan – his birth city. Growing up in vast and glorious Mymensingh, which runs along Old Brahmaputra’s shores and birthed the Nakshi Kantha, Maimansingha Gitika and Shilpacharya Zainul Abedin, the BUET-alum Architect fashions his edifices from the collective memories of his childhood.

Read More

Crafting Timeless Excellence

BHL CERAMICS, the flagship brand owned by BHL GROUP Pvt. Ltd., has evolved over three decades as a dynamic business house and consumer products manufacturer. Since its inception in 2017, BHL Ceramic Co. Ltd. has become one of Bangladesh’s largest ceramic tile manufacturers, symbolizing artistry and creativity. The company’s mission is to reduce reliance on imported foreign tiles and boost domestic production, creating employment opportunities.

Read More

National Budget Thru Turbulent Waters Ceramic Industry Ignored in Budget

The recently unveiled Tk 7.97 trillion national budget for the 2024-25 fiscal year for Bangladesh aims to bringing a balance between controlling inflation and attaining economic growth. Economists, however, caution that higher borrowing and increased taxes on certain goods may prolong inflationary pressures. The budget’s reliance on domestic borrowing could lead to a “crowding-out effect,” restricting financing for businesses, particularly SMEs. Despite a target of 6.75 per cent GDP growth and plans to reduce inflation to 6.5 per cent, achieving these goals is deemed challenging. The budget proposes revenue of Tk 5.45 trillion with NBR tax amounting to Tk 4.80 trillion, leaving a Tk 2.56 trillion deficit to be primarily financed through bank borrowing, which may prompt money printing by the central bank and further inflation. Economists welcome the conservative approach but criticise the plan to increase electricity prices, potentially exacerbating inflation. The budget also includes initiatives for digital transformation and job creation in the IT sector, aiming to attract foreign investment. However, with foreign funding dwindling and significant tax increases on various goods, the effectiveness of these measures in achieving the stated economic targets remains uncertain. Bangladesh’s economic landscape is currently beset by numerous challenges, including stagnant investment, mounting debt repayment obligations, sluggish external sector growth, dwindling foreign exchange reserves, a fragile financial sector, tepid economic expansion, unemployment woes, and widening inequality, apart from soaring inflation. The proposed budget must confront immediate hurdles head-on through targeted budget allocations and fiscal policies. Although the budget is crafted for a single fiscal cycle, it serves as the conduit for translating the government’s economic strategies and political vision into reality. Hence, the proposed budget assumes paramount importance in tackling pressing issues such as safeguarding the interests of the impoverished, low-income, and lower-middle-income households, as well as addressing short to medium-term challenges such as fostering robust economic growth and curbing inequality. Given the prevailing economic exigencies, the FY2024-25 budget must pivot on four critical areas. Dr. Muhammad Abdul Mazid, a former chairman of the NBR, emphasised that this year’s budget cannot be compared to those announced in the past 8-10 years due to the turbulent global economy and several macroeconomic challenges facing Bangladesh. These challenges include a reserve crisis, dollar devaluation against the Bangladeshi Taka, higher inflation rates, and various governance issues. He asserted that overcoming the hurdles facing Bangladesh’s economy in the national budget will be difficult all of a sudden and in a shorter period. Instead, the government should focus on shaping a roadmap to navigate these crises. Dr. Mazid recommended that the budget should not follow the typical patterns of previous fiscal years; rather, it should include reforms in fiscal and monetary policy to address inflation, the dollar crisis, and reserve issues. Additionally, he suggested the formation of a banking commission to address loopholes in the banking sector. To curb inflation, the National Board of Revenue (NBR) could reduce duties on certain products, but effective market monitoring and management are essential to realise the benefits of such duty reductions. Strengthening the NBR’s capacity is crucial for enhanced revenue realisation. Moreover, Dr. Mazid stressed the importance of allowing concerned government organisations, such as the Anti-Corruption Commission (ACC), to operate independently to ensure effective governance. Ceramic Industry Overlooked The ceramic industry, part of the private manufacturing sector, has been significantly overlooked in the proposed national budget. Leaders of Bangladesh’s ceramic sector are urging for the removal of the 15 per cent supplementary duty on local tiles and the 10 per cent duty on domestic sanitary products. They point to rising raw material and gas prices, which have increased production costs. By eliminating these duties, they believe consumer prices would decrease. Md Shirajul Islam Mollah, a Member of Parliament and President of the Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA), had previously proposed removing additional duties on raw material imports and increasing tariffs on foreign ceramic products to the National Board of Revenue (NBR) before the 2024-25 fiscal year’s budget announcement. These measures would reduce imports, save foreign exchange, and boost employment in the country. Despite the relevance of these proposals, none were addressed in the budget. The domestic ceramic market, valued at Tk 8,500 crore. Although domestic companies control over 80 per cent of the market, they face tough competition from imports due to high production costs. On one hand, due to the dollar crisis, L/Cs (letters of credit) are not being opened for importing sufficient raw materials and machinery. Additionally, despite high prices, necessary gas for producing finished goods is not being supplied. On the other hand, amidst dollar crisis, the Bangladesh Bank has announced a second term reduction in cash incentives for ceramic exports—from 10% to 6%—within a span of six months. Meanwhile, the cost of doing business continuously increases. Over the past year and a half, Bangladesh has received loans from the IMF in three installments, but despite implementing several conditions attached to the loan, there has been no such improvement; rather than deterioration. Addressing Fiscal Challenges Economists believe, in the face of daunting economic hurdles, Bangladesh must embark on a prudent fiscal course to steer through turbulent waters. With inflationary pressures mounting and investment stagnating, the budget for the 2024-25 fiscal year demands meticulous attention to fiscal prudence. The government’s traditional reliance on banking sector borrowings to bridge budget deficits exacerbates interest payment burdens amidst constrained fiscal space. Hence, a judicious fiscal consolidation strategy, entailing restrained spending and bolstered tax collection efforts, emerges as imperative. Empowering the Social Sector While substantial investments have buoyed physical infrastructure, the social sector languishes due to chronic underfunding. Education and healthcare sectors, in particular, warrant heightened attention, with allocations in FY2024 falling woefully short of requirements. Fostering human capital development through increased expenditure on education, healthcare, and skills development is indispensable for sustainable growth and inclusivity. Facilitating Small Business Growth Small businesses, the lifeblood of the economy, must be empowered through facilitated access to finance. The banking sector’s burgeoning non-performing loans pose a formidable barrier to lending, stifling entrepreneurial endeavours. Elevating

Read More