Spotlight Featured

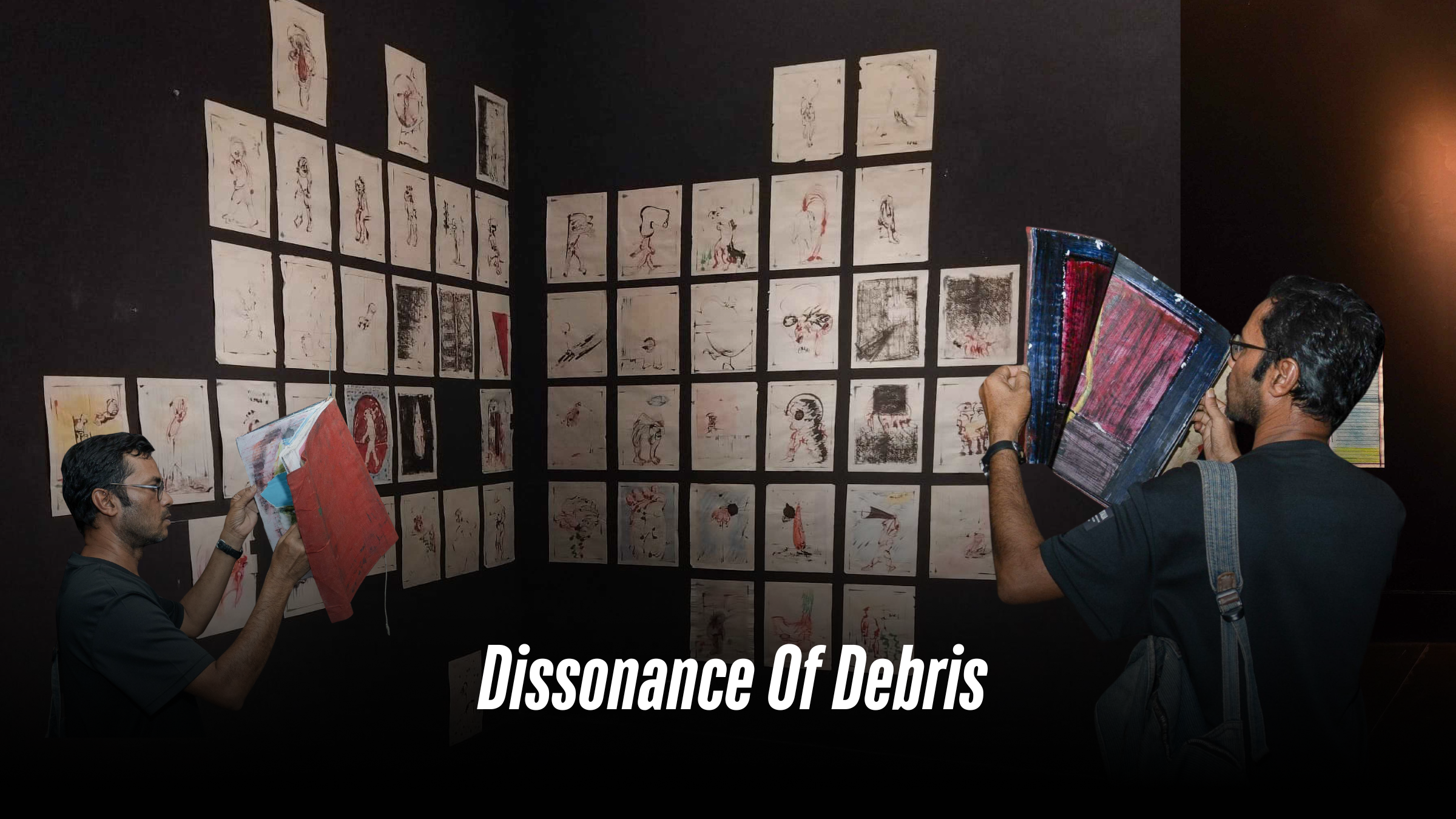

Dissonance Of Debris

From May 17th to 31st, the solo painting exhibition titled “Debris” by Kazi Salahuddin Ahmed adorned the walls of La Galerie, Alliance Française de Dhaka, Dhanmondi. The two-week-long, thought-provoking exhibition featured nearly 30 works on board paper, providing spectators with a glimpse into the artist’s most recent studies. Remembering is a kind of rebellion in Kazi Salahuddin Ahmed’s universe. His solo exhibition, “Debris,” was an uncompromising documentation of human vulnerability. The artist’s recollections of Bangladesh’s 1971 Liberation War seep into modern tragedies—Gaza’s annihilation, the Rohingya exodus, and Kashmir’s stifled cries. The paintings didn’t merely show ruins; they also resurrected spirits. Ahmed’s life had several eras of turmoil. Born within a world transformed by partition and war, his early work in the 1980s was abstract, but the twenty-first century tightened his emphasis. The song “Debris” captures this progression. Each piece is a palimpsest, with layers of pigment representing the strata of history, where erasure and evidence fight silently. Ahmed’s use of board paper as canvas makes a statement in and of itself. Board paper repels, as opposed to ordinary canvas, which absorbs, forcing the artist to handle surface tension. The resulting sculptures have a temporary quality, as if they would disintegrate like the makeshift shelters in Cox’s Bazar’s refugee camps. Though anchored in Bangladeshi stories, “Debris” speaks to a lexicon of global migration. The exhibition’s centerpiece, “Babel Fragment” (2024), depicts the mythological tower as a jagged silhouette against a sulfurous hue. Its shattered planes evoke both bombed-out Aleppo and the decaying tenements of Old Dhaka. Ahmed, who has flown from Paris to Islamabad, appears to imply that rubbish knows no boundaries. In “Eclipse of Return” (2024), a skeletal stairway rises into the emptiness, its steps fractured like vertebrae. Nearby, “Archive of Dust” displays a child’s sneaker half-buried in a thick texture that mimics charred dirt “The utter erasure of Gaza, which was once full of life; the ongoing miseries of people in Kashmir; or the hopelessness faced by displaced Rohingyas attempting to make a living in camps in Chattogram—all of this jostles the mind as one attempts to ponder the future of the human race. Furthermore, it is difficult to leave behind the legacy of Bangladesh’s repeated failures to shape a future. The people’s desire for political stability has always been a never-fulfilled dream in our country. The demise of the authoritarian dictatorship has undoubtedly allowed everyone to focus on a future beyond the current system, but it appears that things are still breaking apart, leaving us with only emotional rubble,” observed famous art critic Mustafa Zaman. The intimacy of “Debris” sets it apart from other forms of protest art. In “Letters Unsent,” bits of Urdu and Bangla letters emerge behind layers of gray, like voices muted by time. The piece is similar to Ahmed’s 2018 series on refugee diaries, but the language is virtually illegible—a metaphor for history’s selective memories. Written By Shahbaz Nahian

Read More

In Search of the Mangrove Goddess

Exploring the Sundarbans’ cryptic mangroves may be a weird, larger-than-life experience. When danger occurs in this wide wilderness, instinct frequently prompts one to seek spiritual protection. In such cases, the Sundarbans’ guardian spirit—Bon Bibi or Bono Bibi—is invoked. Bon Bibi is revered by the local forest dwellers as the divine guardian of the region’s treacherous environment. From April 4 to April 20, the Kalakendra gallery at the capital’s Lalmatia featured “In Quest of Bono-Bibi,” a mixed-media solo exhibition by artist Saidul Haque Juise. Juise, known for his precise craftsmanship, bright masks, and three-dimensional compositions, returned with a solo display following a long absence. Bon Bibi’s mythology is unique in that it combines both the Islamic and Hindu traditions, and it is commonly held that invoking her name in times of crisis promises divine assistance. The stories related to Bon Bibi are woven in a rich tapestry of mythology, which prodded Juise’s psyche when he was a child. Later in life, deeply touched by the Sundarbans’ environmental deterioration, he created this body of work as a lament and devotion to nature. This anthology, with its recurring themes of environmental concern and political overtones, combines lyrical extracts from folklore or shloks related to Bon Bibi with his own storytelling. The birth of these artworks dates back to the COVID pandemic. A time when despair loomed large. It was during this emotional upheaval that the artist Juise channeled his sorrow, frustration, and fear into a series of expressive sketches. Using vibrant shades of black, green, red, and blue— which are reminiscent of traditional Bangladeshi folk pottery— Juise stained his pages with raw emotion. Later, by combining various materials, such as twisted metal wires, paint, ink, handmade paper, newspaper pieces, etc., Juise enhanced the series even further. He was able to convey Bon Bibi’s holy force and the forest’s ethereal essence through these components. His line drawings smoothly blend with his pen and ink pieces to create complex collages that have a vibrant yet delicate vibe. In the meanwhile, the collection gains a tactile, even unearthly quality from his wire sculptures. The series gives viewers a deep feeling of Bon Bibi’s pervasive atmosphere. Along with his technical finesse, Juise added a unique Bengali flavor to the pieces. He skillfully combined the forms of people, animals, and insects to create flowing silhouettes that convey both motion and motionlessness. These shapes convey a duality: sadness that is subdued yet evident and fury that is controlled but strong. In doing so, Juise creates a collection of work that is both visually pleasing and profoundly significant by balancing artistic form with emotional weight. “In Quest of Bono-Bibi” stands much like an artistic diary that procures the artist’s personal reflections, cultural memory, and the urgent call for ecological reverence. It bridges folklore and modernity, spirituality and artistry—ultimately offering a visual testament of healing and harmony between humans and the natural world.

Read More

Institute of Architects Bangladesh Brings Pohela Boishakh to Life on Its Premises

The Institute of Architects Bangladesh (IAB) welcomed the Bengali New Year in vibrant style, hosting its first-ever Pohela Boishakh celebration on its premises. Titled “Esho Mati Notuner Ahobane”, the event was a colourful and cultural affair that reached beyond the architectural fraternity. Architects’ spouses, children, and extended family were warmly welcomed. The idea was simple: to celebrate the new year and the people who stand behind the scenes of every great architect. Festivities began at 3 PM, as the rhythmic beat of traditional dhol set the tone. Architect Asif M Ahsanul Haq, Convener of the Bengali New Year Celebration Committee, opened the event, inviting everyone into the heart of the celebration. With warm smiles and colorful attire, attendees embraced the spirit of community and enjoyed the laughter and tradition with their extended family. The IAB grounds were transformed into a festive fair, with interactive cultural corners drawing crowds throughout the day. Children gathered around clay artists and potters, their hands deep in clay, learning to mold traditional shapes. Nearby, shitol pati (cooling mat) weavers demonstrated their age-old techniques, encouraging young participants to try their hand at weaving. A painting zone was also set up, where children were free to create without the pressure of competition. Their artwork was later displayed, showcasing unfiltered creativity and color. Laughter echoed from the crowd gathered around the Putul Nach (puppet dance) and magic show, where entertainment delighted audiences of all ages and reminded everyone of the charm of folk performances. At the heart of the event was a bustling Meena Bazaar, alive with the flavors of tradition. Stalls served familiar favorites—muri, murki, naru, moya, samosa, beguni, lemonade, and kacha aam er shorbot—while architects and their families showcased their creative talents through stalls featuring homemade food, traditional sarees, books, paintings, and handmade crafts. It was a beautiful blend of personal passion and cultural pride. Major industry sponsors, including Berger Paints Bangladesh, Italiano Marble and Granite, Indigo Marble and Granite, Tilottoma Group, and Space Couture, added their own festive touch. Their vibrant booths offered free face art, portrait sketches, and a variety of Bengali snacks and refreshments, contributing to the lively spirit of the day. As the sun began to set, the stage came alive with folk songs and traditional dances performed by members of the architectural community. The soulful performance by Sadhu Songo, a renowned Lalon music troupe, captivated the audience with its spiritual melodies. The evening came to a heartfelt close with a collective rendition of “Esho He Boishakh,” followed by heartfelt closing remarks from Professor Dr. Abu Sayeed M Ahmed, President, and Professor Dr. Masudur Rashid, General Secretary of the Institute of Architects Bangladesh. The night concluded with a warm, memorable dinner under the open sky—an evening to remember. This landmark celebration was not just about welcoming a new year, it was about embracing shared roots, honouring cultural expression, and celebrating the bonds that make up the architectural community.

Read More

A City’s Story in Stitches and Strokes

Dhaka’s rapid urbanization is impossible to ignore. This city of relentless energy and transformation is a place where tradition and modernity collide amidst its bustling streets and ever-changing skyline. As the economic heart of Bangladesh, it draws thousands seeking better opportunities. But this comes at a cost: overcrowding, strained resources, and a growing disconnect between the old and the new. Against this backdrop, ShohorNama Dhaka Episode II sought to explore the city’s complexities through art. Launched in early 2024, the project brought together visual artists, architects, artisans, and students from the University of Dhaka’s Faculty of Fine Art to create a tapestry of urban narratives. And the exhibition of this project took place from February 15 to 25 at the level 4 under construction space of the capital’s Bengal Shilpalay. The exhibition was inaugurated by H.E. Marie Masdupuy, Ambassador of France to Bangladesh, on February 15, 2025. Titled after the project name, the multidisciplinary exhibition wove together the threads of urban life, resilience, and creativity. Presented by the Bengal Arts Programme in collaboration with the Britto Arts Trust, ShohorNama II was a visual love letter to Dhaka, its people, and their stories. From large appliqué tents to wood-cut prints, installations, and performance art, it was a celebration of Dhaka’s artistic topography. At its core, ShohorNama was about storytelling. One of the standout features is the Pakghor Project, a community kitchen born out of necessity during the devastating floods of 2024 in the Khulna region. Pakghor provided warm meals to 500 villagers for a week. But it became more than just a kitchen—it became a space for shared stories, resilience, and hope. The Dorjikhana Project takes a different approach, focusing on textiles and their cultural significance. Through appliqué and embroidery, artists explore the connection between traditional practices and the modern garment industry. The project also draws inspiration from Bangladesh’s fading circus traditions. Resulting in a stunning collection of textile art that speaks to both the past and the present. Another striking element of ShohorNama is its use of tents. Historically, tents have symbolized temporary shelter for nomadic communities, and in this exhibition, they represent the fluidity of migration—whether due to natural disasters, economic hardship, or political unrest. The Big Tent installation captured this impermanence, reflecting the challenges faced by marginalized communities. The exhibition also highlighted the collaborative spirit of the project. Workshops with the University of Dhaka’s Department of Printmaking and Department of Craft allowed students to contribute to large-scale works, such as woodcut prints and appliqué pieces. These workshops not only honed technical skills but also fostered a sense of shared purpose, blending individual creativity into a cohesive vision. The exhibition was a feast for the senses! As Dhaka continues to evolve, exhibitions like “ShohorNama Dhaka Episode II” remind us of the importance of preserving our stories and traditions. Through art, we can find common ground, build resilience, and imagine a better future.

Read More

Where Artist and Audience Intertwined

Amidst the quietness of Lalmatia’s Block F lies Shunno Art Space—like multidisciplinary artists, it’s also multidisciplinary in character. Limited in floor area but with an illimitable heart, the space adorns exhibitions, has a printing workshop set up, and has a café—intertwined. From February 15 to 22, this cozy space hosted artist Sanjid Mahmud’s solo exhibition “Tracing The Distance.” The week-long exhibition witnessed a vibrant crowd, and the inauguration was graced by eminent artistic figures Hamiduzzaman Khan and Mustafa Zaman. “Exhibition visitors observe art passively, only admiring the finished works. They only view; they don’t paint. But here, they were active participants. They picked up brushes and poured their emotions into the canvasses. Even those who don’t know how to draw found themselves painting. Their raw, unfiltered expressions became the foundation. Then, I stepped in, adding my artistic intervention, blending their spontaneity with my vision.” These words from the artist Sanjid himself perfectly procure the zeitgeist of “Tracing the Distance.” Sanjid Mahmud’s “Tracing the Distance” was an artistic co-production between the artist and the exhibition visitors that prioritized real-time cooperation and process over finality. Art, being a collaborative enterprise, carries remnants of prior forms by combining individual expression with common experiences. However, Sanjid Mahmud’s initiative changed the attention away from linguistic borrowing and toward overlapping artistic expressions in the moment, resulting in a dynamic interplay between creator and participant. Visitors at Shunno Art Space were greeted with empty canvases and encouraged to add spontaneously. The act of production was valued over passive viewing, encouraging people to leave their mark on the canvasses however they liked, be it sketchy motions or painterly strokes, regardless of their creative ability. This fun and engaging method relieved the pressure of normative practices, allowing for raw, unfiltered expression. Sanjid Mahmud then stepped in, responding to these inputs without striving for a certain style result. The end result was a body of work that defied decisive conclusion, undermining modernist conceptions of linear progression and chronological time. The title of the exhibition, “Tracing the Distance,” emphasized its purposeful break with the logic of modernity, which minimizes artists’ territorial consciousness and frequently limits them to historical circumstances. Through the process of collaborating with his audiences, Sanjid Mahmud challenged the conventional understanding of art as a “significant form” or a refined praxis. In order to reveal the fluid, communal character of creativity, he instead opened the gallery’s “white cube.” By means of this collaborative approach, the artist stimulated a reconsideration of the connections among art, artists, and the art community. Thus, Shunno Art Space transformed into a place of reflection where both appreciation and creation are rethought. By emphasizing the act of doing rather than observing, “Tracing the Distance” questioned established hierarchies and honored the beauty of group, unplanned expression while providing a novel viewpoint on the ever-changing conversation between shared and individual artistic languages. Written By Shahbaz Nahian

Read More

‘The Story of Art’ exhibition: Of art and altruism

Organized by Dhaka Storytellers from February 8 to February 13, the lush gallery space Aloki Greenhouse in the capital’s Gulshan hosted an exhibition titled The Story of Art. The exhibition boasted a stunning collection of 80 to 90 artworks, captivating audiences for a week. Curated by Syeda Adiba Hussain, co-founder of Dhaka Storytellers, The Story of Art was more than just a display of artistic excellence. This was Dhaka Storytellers’ second art event, following the charity exhibition Art for Charity in August 2024. In the same vein, The Story of Art supported a larger cause, with a portion of the proceeds donated to five schools and one college in Sylhet, demonstrating the power of art to create tangible change beyond gallery walls. Beyond the beauty of its displays, the exhibition underscored the immense power of art to inspire and drive change. By merging artistic excellence with humanitarian efforts, it aimed to uplift communities, empower individuals, and support crucial social causes. Having been in the making for almost a year, the exhibition was carefully planned to bring together some of Bangladesh’s most celebrated artists. The lineup included some of the country’s most notable names, such as Rafiqun Nabi, Monirul Islam, Hamiduzzaman Khan, and Kanak Chanpa Chakma. Furthermore, the exhibition commendably featured artworks by several emerging artists, creating a dynamic collection that bridged generations of artistic expression. From simply beautiful paintings to thought-provoking sculptures, The Story of Art was also an opportunity for both seasoned and budding collectors to acquire unique pieces while contributing to a noble cause. The grand opening on Friday, February 7, set the tone for the week-long exhibition. The launch was attended by an invitation-only audience, including the participating artists, their families, media professionals, and notable guests. As the exhibition drew to a close, it left behind more than just a collection of breathtaking visuals; it also left an indelible impression on those who visited. The fusion of artistic expression with social commitment deeply moved attendees, inspiring them to consider the vast potential of art beyond aesthetics. The exhibition carried a narrative that extended far beyond the gallery walls, reinforcing the idea that art is not merely to be observed but to be experienced, felt, and acted upon. The event was about more than just admiring artworks—it was about creating a shared vision where artists, curators, and spectators all committed to a cause bigger than themselves. It demonstrated that art has the ability to transcend traditional boundaries, reaching into the hearts of individuals and communities, sparking conversations, and inspiring action. Ultimately, The Story of Art was a celebration of creativity’s ability to inspire, connect, and transform lives. The week-long show was a powerful testament to the transformative synergy between art and altruism. It showcased how art exhibitions, when intertwined with a greater purpose, can spark meaningful change. Written By Shahbaz Nahian

Read More

Brishtite Roder Kona’ reminisces Kazi Abdul Baset

The ongoing exhibition titled ‘Brishtite Roder Kona’ at Bengal Shilpalay lets new audiences be introduced to the works of one of the finest artists from Bangladesh, Kazi Abdul Baset. In an age when electricity has reached even the most remote corners of Bangladesh and air conditioning is ubiquitous, the image of a woman cooling herself with a traditional handheld fan may appear to be a relic of the past. However, this simple act of seeking relief from the heat was immortalised in the works of Baset. While his works are rarely exhibited these days, the exhibition at Bengal Gallery in Dhanmondi has provided a unique opportunity to view a comprehensive collection of his work. The exhibition features 72 pieces in a variety of mediums, including acrylic, pastel, charcoal, watercolour, and ink drawings. The artworks are all from private collections and have been generously shared to introduce Baset’s genius to a new generation. Kazi Abdul Baset’s legacy is enormous but unappreciated. Baset, a humble and introverted guy, was recognised for his plain pyjama and grey panjabi outfit, as well as his rigorous guidance of his students. He received a Fulbright scholarship and studied in Chicago from 1963 to 1964. Baset’s work has a unique blend of figurative and abstract styles. Despite his modernist approach, Baset’s themes frequently revolved around the simplicity and beauty of rural life, capturing its essence with profound depth. His depictions of rural women and domestic life added a new dimension to modern Bangladeshi art, specially his paintings of woman with a fan becoming almost a trademark of his artistic identity. Baset had a close relationship with fellow artist Mohammad Kibria, another shining light in Bangladesh’s art history, and analogies between their works were frequently made. Their mutual influence and inspiration resulted in considerable artistic synergy, which shaped Bangladesh’s art scene in the 1960’s. Baset began his career as an art teacher at Nawabpur High School, where other notable figures such as Mohammad Kibria and Murtaza Bashir taught. Baset’s artistic development—from his early realistic images of rural life to his later experimentation with abstraction and return to realism—reflects a dynamic and diversified artistic journey. This show at Bengal Gallery is a fitting tribute to the brilliance of Kazi Abdul Baset, providing spectators with a unique opportunity to immerse themselves in the works of a master who caught the soul of Bangladesh with unsurpassed sensitivity. Presented by Bengal Arts Programme, the exhibition walls adorns the works of Baset which he produced between the 1960’s and 1990’s. All the works being showcased are collected from the personal collections of Abul Khair, Abul Hasnat-Nasimun Ara Haque, Matiur Rahman and Luva Nahid Choudhury. Open for all, the exhibition commenced on 8 November 2024 and will run till 11 January 2025. Written by Shahbaz Nahian

Read More

Body and the Map: Of wounds and Hope

Beautifully curated by Sharmillie Rahman, the exhibition “Body and the Map” took place on Bengal Shilpalay between 15 and 28 December, 2024. By engaging viewers to contemplate the interaction of power, identity, and transition, “Body and the Map” was more than just another decent exhibition that had the July-August uprising as its subject matter; the exhibition not only acted as a stark reminder about what must not be forgotten but also intrigued the audiences to introspect. Consisting of the artworks of ten multidisciplinary artists, many of whom were active participants in the mass uprising that overthrew a long-standing regime, “Body and the Map” was a riveting look at societal upheaval in the aftermath of that student-led mass rebellion. The show, based on the collective memory of Bangladesh’s last July-August, is both a reflection and a debate about the force of resistance, the weight of trauma, and the possibility of change. Their work delves into the complicated reality of a country dealing with its old and fresh scars and the tiers of collective psychological state of the mass after the newfound independence. The participating artists were A. Asan, Afsana Sharmin, Ashang Mong, Farzana Ahmed, Mong Mong Shay, Niazuddin Ahmmed, Palash Bhattacharjee, Rasel Rana, Razib Datta, and Ripon Saha. The July-August uprising was characterised by an unprecedented feeling of urgency, as residents defied persecution to demand justice, equality, and dignity. However, the road to liberation came at a high cost, with bodies mutilated, lives lost, and a collective psyche permanently transformed. The show explores this dichotomy, emphasising the body as both a personal and societal vessel for history, pain, and resilience. The artworks that were adorned by the gallery space delve deeply into the concept of the body as a source of memory and resistance. Whether through physical depictions or abstract interpretations, the ten artists highlighted how the human body bears the weight of institutional injustice and governmental violence. The visual narratives starkly remind us about biopolitical disposability, demonstrating how individuals became victims of normalised violence during the authoritarian system. The relationship between body and land appears as a repeating pattern, emphasising identities defined by culture, religion, race, and gender, all of which intersect within a nation’s sovereign borders. However, these links are loaded with tension, since the scars of authoritarian authority and systematic impunity are etched on both the body and map. In the aftermath of this historic movement, “Body and the Map” illustrated the dialectics of trauma and renewal, hopelessness and optimism. The exhibition stressed the importance of open discourse and the reframing of identity and government as centralised power disintegrates and something new emerges. Despite recollections of terror, violence, and loss, the artworks elicit a cautious hope. The collective body politic, though scarred, remains resilient, signalling a determination to redefine itself and the map it inhabits. Written by Shahbaz Nahian

Read More

Liminal Horizon: Body, existence & Introspection

“Liminal Horizon,” the solo exhibition of artist Sanad Biswas that took place between 14 and 7 January at the capital’s Kala Kendra, is one of the most fascinating sculpture exhibitions in recent memory of post-pandemic Dhaka’s vibrantly growing exhibition scene. From quirky humanoid figures and brightly coloured and inflated ballooning bodies to disembodied internal organs, Sanad’s sculptures have an aura of eerie sensuality mixed with humour. They appear visually strange to our eyes, but the feelings we perceive are bizarrely familiar to our soul, and they intrigue questions about our fragility and existence as human beings, living and surviving amongst the complexities of the modern world. Although primarily a sculpture exhibition, it consisted of relevant paintings, drawings, installations, and photographs of performance art by the artist as well. This exhibition is also like a diary of Sanad’s almost two decades of art practice. “The world that we live in right now has its tiers of complications. And as human beings, our immediate surroundings and even global circumstances in this era of a world connected through the devices in our hands always have an effect on us, both mentally and physically. The artworks that are shown in this exhibition are artistic manifestations of my psychological journey, how I reacted to certain contexts. For example, the characters in my works are sometimes satirical, sometimes dramatic and colourful, and sometimes they suffer from existential crises!” said artist Sanad Biswas. Another highlight of this exhibition is the beautifully done curation. Curating a show inside a space like Kala Kendra is always challenging, as it is basically a ground-floor part of a residence and not originally designed to be a gallery. But artist Sanjid Mahmud gracefully accomplished the difficult task of dealing with such a space and devised a neatly designed exhibition. “This exhibition was not pre-planned. Sanad had been devotedly working for a long time now; hence, naturally, he has an assemblage of amazing artworks that has a certain coherence that subtly reverberates that they are Sanad’s works. Later, we decided to organise this exhibition. And as a curator, designing a sculpture show inside a space like Kala Kendra was also a challenging task,” said artist Sanjid Mahmud, who is the curator of the exhibition. “Compared to the existing types of sculpting practice that we see in our local art scene, Sanad’s works are starkly different. His works are compelling even in the standard of global contemporary art,” Sanjid further added. With their few other artist friends, Sanad Biswas and Sanjid Mahmud runs their art collective Daagi Art Garage. Although not a familiar name outside our local art scene, this Dhaka-based young art collective, is one of the finest in their genre in Bangladesh. Daagi’s own space, Studio Bhashkarmi, is in the capital’s Hazaribagh area. Written by Shahbaz Nahian

Read More

‘Solastalgia’: Fragments of a fading horizon

From October 19 to November 16, Platforms will host Auntora Mehrukh Azad’s solo exhibition “Solastalgia: Fragments of a Fading Horizon,” at its gallery in Pragati Sarani, Baridhara, Dhaka from 11am to 8pm daily. Her work is inspired by the universal and personal feelings of environmental change, with a particular focus on Bangladesh’s rivers and landscapes. Azad’s art explores the impact of environmental loss, displacement and transformation in rural and urban landscapes from the Sundarbans to Dhaka. All the art enthusiasts, collectors, and connoisseurs are invited to explore Azad’s evocative works.

Read More

AkijBashir Group and Edison Real Estate Forge Strategic Partnership to Enhance Customer Experience

AkijBashir Group and Edison Real Estate Limited, have formed a strategic partnership to

enhance customer value and offer exclusive benefits. This collaboration will provide exclusive

perks to members of the Edison Royal Club, a loyalty program designed for Edison Real

Estate's esteemed clients.

Spotlight Artisan Ceramics at the forefront (04)

Amongst the Royal collection in the Buckingham Palace resides gold-covered renditions of Artisan Ceramics. From a company struggling to export, to winning the national export trophy five times in a row, Artisan Ceramics has seen 3 times expansion over the past few years. The entirety of a company’s growth and success inevitably relies on the decisions made internally. Artisan Ceramics Ltd. suffered significant loss until 2011. With new leadership under Finlays, and a change in the modality of business and redesigning, it now has a factory constructed across six acres of land in Sreepur, Gazipur, and a capacity of producing 10 million pieces of assorted premium quality porcelain tableware annually. The current expansion will raise this capacity to 22 million. Artisan Ceramics is an export-oriented tableware company that supplies to over 20 countries across Europe, America, and Asia, and has evolved into a leading manufacturer with no stop to its growth. The company has a contribution of 12-15 percent in the national export revenue. Surely, success in such a short time is a wonder on its own. To find out more, Ceramic Bangladesh Magazine author recently had the opportunity to discuss the adaptations of Artisan Ceramics that led to its success, with M. Mamunur Rashid, CEO of Artisan Ceramics Ltd. Here’s what we’ve learned: The first adaptation Artisan knew Saggar firing was wasteful Saggar or Saguaro is a covering used over ceramic ware when under intensive firing in the kilns. This protection helps safeguard the ware from coming in direct contact with the Kiln, debris inside the kiln, and other gases and smoke. The problem with saggar firing is that the saggar heats up first and then transfers the heat to the product; this makes the process 15-hour long cycle. With Artisan’s adaptation, open and fast firing, it’s a six-hour firing process. “Time-wise and price-wise, Saggar is inefficient. Again, there is the cost of the man behind the machine,” says Mr. Rashid. Fired three times for a longer life! “I have traveled across more than 10 countries just to see the technology companies have adopted, and learned, that the type of products we tend to manufacture are widely unavailable,” said Mr. Rashid. “We have products that have been fired three times, which make them much more durable. These products are more popular in Europe since they are more durable and can withstand knives and forks,” he added. At Artisan, products are fired at high degrees of temperatures — 1330°C to 1350°C, about 100° higher than the global rivals. Discussing global demand with relevance to this particular firing process, we find: “The hard glaze we are using, makes the product stronger, more scratch-proof, and absorption free,” said Mr. Rashid. The global demand has shifted towards such products because of such features. Raw materials sourced from around the world Artisan Ceramics sources its raw materials from almost every corner of the globe –the UK, Germany, Italy, New Zealand, Vietnam, Japan, China, and India are some of them. The two types of minerals that make up for 50% of the body, feldspar, and quartz, are brought in from Rajasthan, India. The company also imports alumina which is used to make the body stronger and helps meet HoReCa standards. “Using the best quality raw material with a natural colour is important because the glaze is translucent and the body colour is what you see,” he said. These designs are in trend now and a personal favourite of Mr. Rashid. The company even imports from specific mines. Furthermore, Artisan buys the best quality gold from Heraeus Germany and colors from Izawa Pigments, Japan. Innovative Designs that go well with the trend, and the technology behind it. Artisan is constantly working on new designs. “We are innovating and have recently created double-layer body tea cup that keeps tea & coffee warm for a longer period of time,” Mr. Rashid mentioned. The design depends on customer trends and comes in cyclic order, says Mr. Rashid. Something that is currently trending are reactive glazes where you allow the finishing to be exactly how the kilns are making them fascinate many people. “Keeping up with the ever-evolving trends is a constant challenge, but traditional designs have resurfaced and are a popular preference now,” said Mr. Rashid. Artisan will be introducing a certain collection inspired by the Rajasthani culture. A designer from Sri Lanka by the name of Sudath Fernando is also coming in to train employees. Stay tuned with us for future features. Regarding technology, he said: “We want to make our factory fuel efficient. Our dryers are like ovens that collect heat and reuse it. I have visited a few factories in Europe and have seen how they are doing things, we have called SACMI, Italy, to help us upgrade.” The machines at Artisan’s factory are from the USA, the UK, Japan, Taiwan, and China. Artisan has taken green initiatives- they refine and reuse 90% of wastewater, collect rainwater in underground tanks, and reuse heat from the ovens. The company purifies water to the extent that it can be used for irrigation. “Every factory is concerned and the government is putting emphasis on sustainable approaches,” stated Mr. Rashid. Artisan’s plan to sell in bulk Following the recent expansion, Artisan is now concentrating on bulk buyers- examples would be hypermarkets. The marketing team is also trying to bring about a trend change by promoting the use of porcelain over bone china. This is because the water absorption of Bone China is high, it loses colour, and porcelain survives longer. Ultra Bone Porcelain: the newest innovation from Artisan Some customers are price-centric and some look for quality. That is why Artisan needed to innovate a new product retaining the same mechanical strength of pure porcelain and exceptional whiteness that was sure to win people over. Henceforth, came the Ultra Bone Porcelain. Mr. Rashid introduced a special body that can beat the competition and customers are willing to pay premium price for it. Artisan performs CSR Artisan gives education

Read More