Time is NOW for eco-friendly clay-made roofing tiles and now is TIME for tile makers. They are the Bangladeshi makers of clay tiles who have gone global as their tiles have opened up the door of a huge export possibility, especially to Europe. The making of clay tiles is simple but it needs amazing artistry as well as artisanal skills. Fluffy mud is made by mixing soil and water. It then dries in the sun and is burned only to turn into clay gold. The artistic tiles with Bengal clay have revolutionised the style. However, clay artisans were once about to lose their hopes and dreams with their centuries of tradition. They then have turned the corner and things are looking up with the coming of the modern machine-driven industry. The clay artisans have turned around to weave a new web of hopes and dreams.

Famed for its ‘Tiles Empire’ over the years, Satkhira has eco-friendly roofing tiles to its credit. Kolaroa Bazar in Kolaroa upazila, some 18 kilometres of district headquarters, is one of the prosperous trading points in Satkhira. Murarikathi village is located just 1.0 km away from the upazila headquarters along the border of the district. The artisans of Murarikati-Sripatipur have built an empire of various sorts of roofing tiles. The village, also called Kumarpara, has now got the moniker ‘Italy Town’ plausibly for exporting a massive volume of tiles to the European country. Tile factories used to produce 700-800 containers a year just a few years back. Some 300-400 container tiles were exported to Italy through Mongla seaport. The price of the product per container is average US$ 15000

Eco-friendly tiles

Eco-friendly tiles There is a huge local market for roofing tiles if these hand-made tiles are given a more modern touch and the initiative is taken to use them as an artisanal tile in buildings and structures. During the British raj, cottages, offices or residences of the gentlemen used to have tiles at the peak that are still visible in the ancient architecture of Britain. Although a large number of potters have left Bangladesh, some in Kolaroa have kept the traditional tile industry alive in the frontier district. Until the mid-1960s, there were hardly any houses in the country that did not have a tile-made house or two. As it came cheap, roofing tiles became popular after rice and wheat straw-built structures. The structures were felt cool and comfortable during the summer.

How Palparaenters European market

The traditional tiles industry almost sank into atrophy when the potters associated with tile production left the country in the mid-60s. Satish Chandra Pal, a native of Palpara in Kolaroa, started crafting house canopy tiles in about 1952. From there, potters spread across the country. As Mr Satish Chandra died after independence, the pottery business simply collapsed. Due to their deep-rooted poverty, many artisans left their ancestral profession. With the passage of time, the potters have changed. They are now making tiles using clay. In 2003, local potters created a revolution by pouring clay into a wooden frame and drying it in the sun, making Bengali tiles in line with Italian design. Since then, Bengali tiles are being exported to Italy

How are the legacy-bearers?

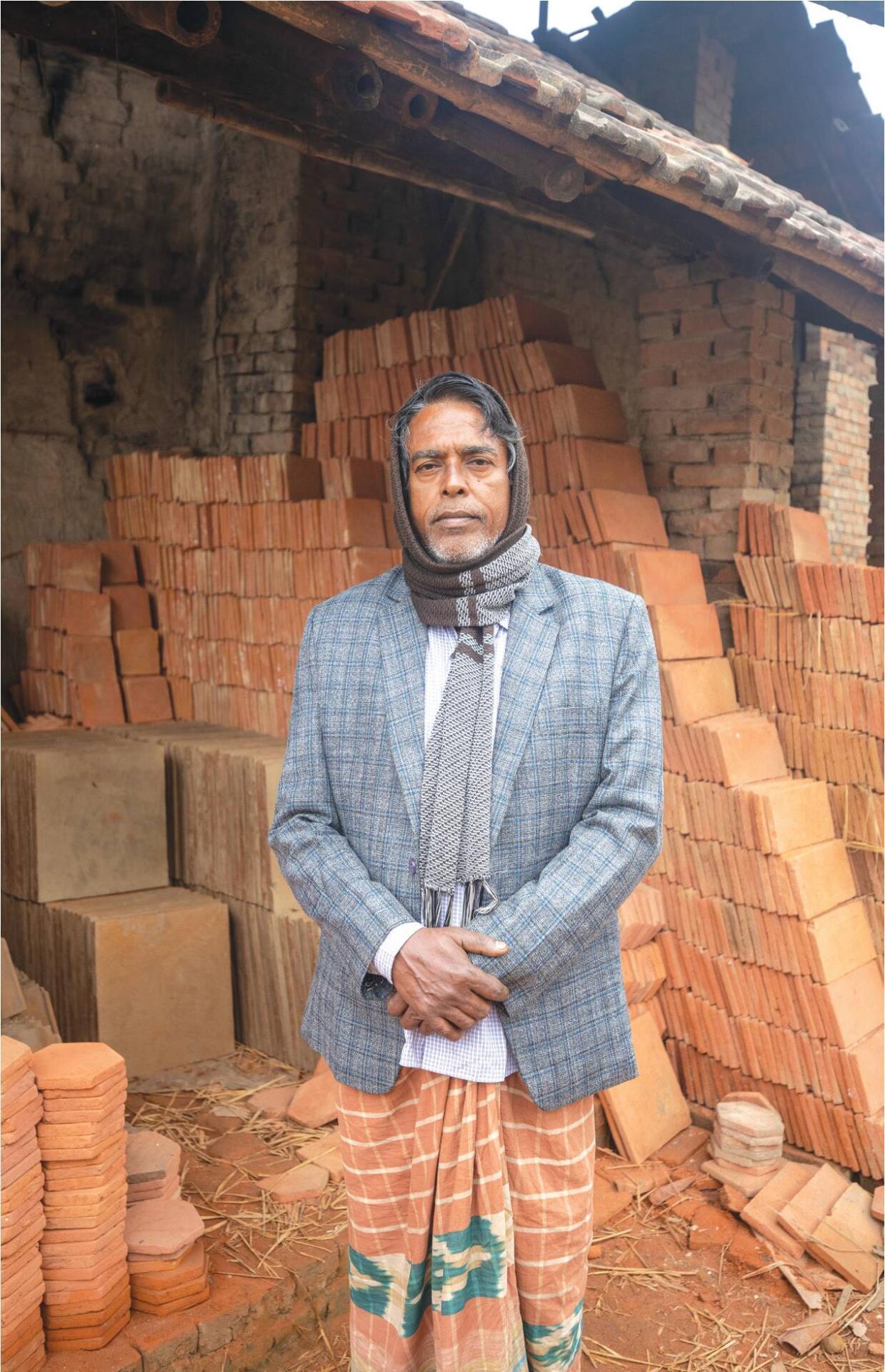

Among those artisans is Gostho Chandra Paul, the president of Kolaroa Upazila Tali Malik Samity [Tiles Owners Association] and also proprietor of Kolaroa Clay Tiles. But he now struggles to survive as his long-cherished art is on the verge of extinction for a number of reasons. The 60-year-old Paul, who has a three-member family, is producing 1,000 units of tiles at his factory per diem. Each unit is currently being sold at Tk 8.0. He earns Tk 1.6-1.7 million per annum. Getting disgruntled and disappointed over the waning business situation, most owners and workers associated with this industry have already lost their jobs. Mr Paul observed that modernity has affected almost all sectors of the country. However, the tiles industry is yet to get the touch of modernity. Production costs have increased manifold, but the price of tiles has not increased. Mr Paul’s forefathers launched crafting eco-friendly roofing tiles in 1947. However, it all started for Mr Paul in 1986 when he set himself up in business with Tk 3,000 only. Ten workers were employed at his factory when he started crafting eco-friendly roofing tiles traditionally. His uncle told him to be self-reliant and build his own future through the long traditional business, which he acquired lineally. But at least 40 tile factories got shut down in the past six years due to their persistent business losses. Now, the number of factories there is about 12. Almost 6,000 workers become unemployed and only 600 are absorbed elsewhere. For generations, the Pal community in the locality has been contributing a lot to this thriving sector. Mr Paul is also committed to continuing their forefathers’ business at any.

In 2003, this clay tile was first exported to Italy. Businessman Ruhul Amin exported the eco-friendly tiles there. Arno Export Import, Shuvo Trade Limited, FH Khan Limited, Maa Cottos Inc., Nikita International, Koto Innovator, JK International, Polo Epo Organic Tiles and D Chandra Paul have followed Mr Amin’s footsteps. They are exporting tiles to Italy, Dubai, France, the UK, Australia, Germany and the Netherlands. Mr Chandra Paul, proprietor of Kolaroa Clay Tiles, said Mr Amin continued to look for suitable soil in different parts of the country for exporting tiles to Italy. Finally, Mr Amin found his desired soil in Murarikati area.

He is the pioneer in exportable tile business. As the number of roofing tile factories increased in Kolaroa until 2019, the stock remained high at the time. Every year, 300-400 containers of tiles went to Italy. Such tiles are manufactured and sold for 6-7 months in a year. Usually, tile-making season starts from October and continues until the May-June period. Tiles cannot be crafted during the rainy season. Foreigners are using the tiles for floors and walls of their houses because of its eco-friendly nature. Clay tiles are being sold at Tk 280 per unit in Dubai. Mr Paul said Dan W Mozina, former US ambassador to Bangladesh, also visited the tile factory for their uniqueness and environment-friendly tiles. The diplomat was then impressed with the tiles of various eye-catching designs in Palpara.

Why is the export market diminishing?

The roofing tiles export market for Bangladesh is shrinking fast as India is consistently grabbing a large slice. Unfortunately, quality is an issue and so is market competitiveness.

Expansion of local and global markets The local market turnover stands at only Tk 10 million now. The global roofing tiles market size was valued at $30 billion in 2019 and it is projected to reach $40 billion by 2027, registering a compound annual growth rate (CAGR) of 5.20 per cent from 2020 to 2027. The market is growing, thanks to shifting focus to eco-friendly household products. Local tiles factories are grabbing nearly 60 per cent of the domestic market, whereas China, India and Vietnam are sharing the remaining portion. Local market leaders include Mirpur Ceramics Limited, Tradexcel Ceramics Limited, and Conforce Ceramic and Refractories Limited.

In this regard, Vice Chairman of Export Promotion Bureau (EPB) AHM Ahsan told Ceramic Bangladesh that quality, attractive design and price competitiveness are a big issue in terms of exports. However, a bigger company has higher advantage in exporting. Because buyers are more interested in buying the maximum quantity of products from a single firm. In this area, India is much ahead of Bangladesh. As the tile factories of Satkhira are small enterprises, some difficulties remain for them in terms of exports. He said there is no detailed information about the local clay tiles producers of Satkhira as they are not registered with the EPB. Advising formation of an association of tile manufacturers and proper communication in this regard, he said, if they want to participate in the national and international fairs of EPB, they will be given full support. This will allow them to interact directly with foreign buyers and understand their needs and choice. Bangladesh embassies and commercial missions abroad can also be used for the purpose. At present, these tiles are exported to Europe and America through third parties, so the producers have no direct idea about the international market and prices. Moreover, many types of certification are required to enter the international market. Currently exporting through third parties, they also get cash on price much later. That reality discourages them to export. Citing the example of the Export Competitiveness for Jobs (EC4J) project of the Ministry of Commerce, he said that four sectors – leather, plastic, light engineering and agro-processing – are now being given technical assistance and matching grants by setting up technology centres under its purview. In future such centres and cash incentives can also be provided for exportable clay tiles.

Chairman of Bangladesh Small and Cottage Industries Corporation (BSCIC) Md. Mahbubor Rahman said that Satkhira’s tiles factories are located in private residential areas outside the BSCIC industrial area. This industry is not organised there. They have no guardian, no association, no registration and no license. They have also no modern regulations required for international business. BSCIC has sought to extend necessary cooperation to them and has already held a meeting with them. They are first advised to form and register an association. Locally they include rivalries and syndicates. There is uncertainty over pricing. Many of them competitively cut prices to capture the market. For this reason they stumble and face loss at some point. Moreover, the price of soil and transportation costs have increased in recent times. Fuel price has increased. Wages of workers have also increased. There are also allegations of extortion. Some local influencers are involved in it. Now soil has to be collected from a distance of 8-10 kilometres. This industry is quite dependent on nature like sunshine and rain. Monsoon season is not suitable for working. At this time, production costs also increased. A local NGO named ‘Unnayan Prochesta’ is giving them some micro credit. If the manufacturers come forward with interest, BSCIC is ready to cooperate with them to provide advanced design, training and modern technology, he said.

Process of making roofing tiles Soil and silicon oil are the key components for making roofing tiles. Mr Paul collected soil from his localities and oil from some local importers. There is no dearth of soil in the market. He used fuel wood to manufacture tiles. To get a finished product, Mr Paul first collects suitable soil. Then he does the processing in the production line, including crushing, grinding, screening, moisturising, forming, drying up by a dryer, finishing by kiln and sorting to packing.

What stakeholders and businesses suggest? Echoing the predicament facing the local craftsmen, Kolaroa Upazila Chairman Aminul Islam Laltu said, “Our local economy is on the verge of collapse due to the ramshackle condition of the tiles.” Mr Laltu, who lives in Murarikathi village, said he enjoyed the hustle and bustle of local artisans and workers round the clock as the local industry has been able to create a full potential of export opportunities directly through Mongla port. He, however, lamented that local artisans and workers with their families are living a hardscrabble life but they are not seeing a glimmer of light at the end of the tunnel. A competitive business environment is ruined due to their internal feud. The prices of soil and wages were also increasing following the Covid-19 and the global economic turmoil, according to him. Mr Laltu himself and the local administration tried to address this long-standing problem by sitting with the local artisans several times informally. Some exporters happened to be defaulters of loans they received from local associations, cooperatives and banks. They could not even get proper and timely support from banks and local associations. Mr Laltu has sought government intervention and patronage to protect the local century-old heritage.

The beautiful traditional clay tiles have been able to draw the attention of foreigners. The completely hand-made tiles without any machine or equipment were available in the European market. At least 5,000 local people were engaged in factories. Almost all of them have become self-reliant. The number of factories was increasing day by day, according to him. The Kolaroa Upazila Chairman has suggested that a time-befitting policy be adopted to further boost the environment-friendly tiles business in the greater interests of the local people, businessmen, artisans and labourers.

Satkhira Chamber of Commerce and Industry President Nasim Faruq Khan Mithu said his chamber always stands ready to give the artisans all possible support, should they communicate with them and seek help. Due to the pandemic, all the financial institutions, including banks, faced difficulties in disbursing loans, although they are providing loans in most cases, said Mr Mithu, also the owner of M/S Khan Trade. All business bodies, including the Federation of Bangladesh Chambers of Commerce and Industries (FBCCI), always remain supportive and collaborative when addressing such problems, he said, suggesting that businesses raise their issues like pains, pangs, trials and tribulations in an appropriate manner in time to receive the support. The government can extend its support if needed but they should place their problems to the authorities concerned from time to time without any hesitations, continued Mr Mithu. The Satkhira chamber leader said he is committed to raising their issues to the proper forum after investigating their existing business situation. Written by Sajibur Rahman