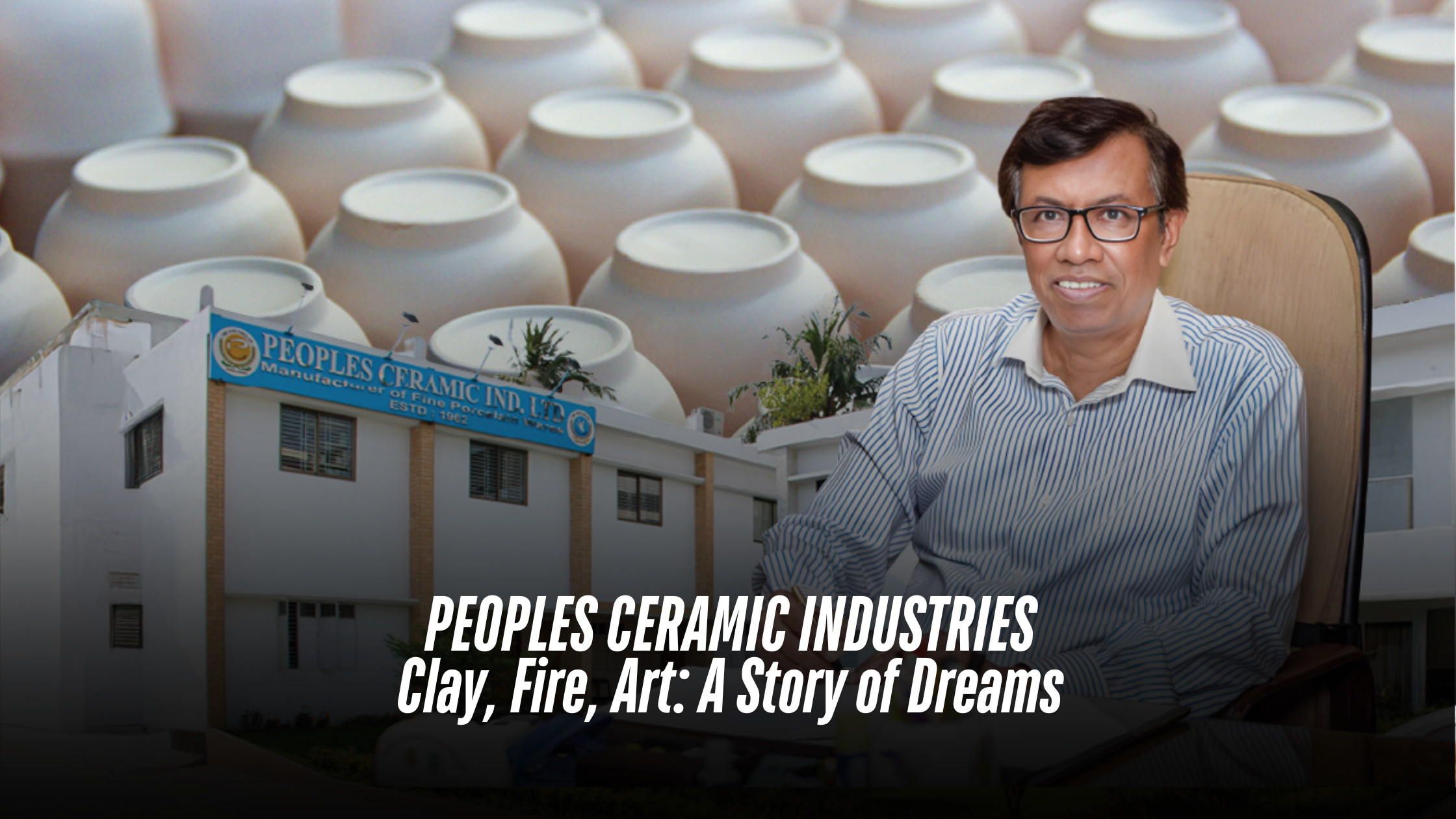

As the morning sun gently illuminates glass windows and casts playful shadows on the floor, a new day’s story unfolds. Beyond the city’s hustle and bustle, skilled hands at Peoples Ceramic Industries Limited (PCI) work tirelessly to craft each perfect piece—an extraordinary fusion of clay, fire, and creativity.

Today, Bangladesh’s ceramic industry has evolved far beyond home décor into a globally recognised brand. At the forefront of this transformation is PCI. Established in 1962—originally known and registered as Pakistan Ceramic Industries Ltd.—the company has grown over 63 years into one of the nation’s oldest and most respected ceramic manufacturers. Its reputation for high-quality porcelain tableware, sustainable technology, and a robust international presence speaks for itself.

In this edition of Ceramic Bangladesh, we sat down with Lutfur Rahman, the Managing Director of Peoples Ceramic Industries Ltd. A visionary in his own right, Lutfur has both preserved and expanded his father’s legacy, positioning PCI as a key player in Bangladesh’s industrial evolution.

A Legacy Built on Vision and Integrity

Lutfur Rahman began the interview by proudly showing a photograph of his father, Ansar Uddin Ahmed—the mastermind behind Peoples Ceramic. A civil engineer who graduated from Ahsanullah Engineering College (now BUET) in 1947, Ansar Uddin was driven by an enduring desire to serve his country—not through bureaucracy but by creating something truly meaningful.

After a brief stint in the government sector, he pursued his entrepreneurial dreams. In the early 1950s, he founded United Engineers, securing a first-class license from the government. His firm was responsible for several prominent constructions that still stand today, including the Ceramic Institute in Tejgaon, Dhaka Polytechnic Institute, and Chittagong Medical College and Hospital. It was during his frequent visits to the Ceramic Institute that the idea for a ceramic factory was born.

Reflecting on his father’s journey, Lutfur shared, “The relationship between children and their parents has always been special. I grew up watching my father work relentlessly, with my mother by his side supporting every step. His singular desire was to create a new industry and leave behind porcelain tableware as a legacy to improve the quality of life for our people. To realize this dream, he embarked on a long, challenging journey filled with obstacles. He always said, ‘To achieve something, one has to give up something, and there is no shortcut to building a solid foundation.’”

The Birth of Peoples Ceramic

In 1962, Peoples Ceramic Industries Ltd. was established with a clear and powerful vision—to provide affordable porcelain tableware for ordinary people. At a time when ceramic products were considered a luxury, Mr. Ahmed aimed to bring dignity and elegance to everyday dining. The company chose to manufacture European-style tableware, targeting both local tastes and future export opportunities. By 1982, PCI had successfully entered the international market, with its porcelain products welcomed in Holland and the United Kingdom.

Located in the Tongi Industrial Area—a prominent industrial zone in Gazipur, just 20 kilometers from Dhaka—PCI started with basic housewares, tea cups, and saucers designed primarily for restaurant use. Over time, the product line expanded to include institutional ranges catering to hotels, restaurants, and the broader hospitality sector. Reflecting on the company’s humble beginnings, Lutfur recalled, “Peoples Ceramic was established in 1962, with the technical support of Sone Ceramic, Japan. At that time, Japanese engineers stayed in Dhaka to supervise the installation and production process. In the early days, our factory ran on furnace oil, and our products gained popularity right from the start.”

Mr. Ansar Uddin Ahmed, who served as managing director of both Peoples Ceramic Industries and Standard Ceramic Industries Ltd., passed away on August 17, 2005. He also served as the first President of the BCMEA from 1992 to 2002, playing a vital role in revolutionising the export of local ceramics. “Tajma Ceramics, established in 1959, was the pioneer in manufacturing earthenware. However, PCI was the first to introduce porcelain production in Bangladesh,” Lutfur explained. According to him, PCI was formally inaugurated by then Industries Minister Dewan Basit and the Japanese Ambassador, with commercial production beginning on June 23, 1966.

Overcoming Challenges and Embracing Innovation

Marketing large-scale production in the early years posed a significant challenge. To overcome this, Mr. Ahmed ventured into the Pakistani market, successfully competing against two established factories. PCI’s hard-grade porcelain quickly won acceptance, carving out its niche within the subcontinental market.

The company has consistently invested in state-of-the-art technology, global raw material sourcing, and upgraded machinery to guarantee quality and cost-effectiveness. This forward-thinking approach has enabled PCI to stay ahead of industry trends for decades. In 2009, the company introduced decal printing—initially using basic logos—and by 2012 had established a fully automated decal printing facility, expanding its design capabilities and reinforcing its brand identity.

Aesthetic Diversity: Designs That Tell a Story

Today, PCI offers a diverse range of tableware, neatly categorized into housewares, hotelware, and giftware. The company produces approximately 13 million pieces of porcelain tableware annually and employs nearly 712 people. These milestones stand as a tribute to its commitment to quality and innovation.

The Road Ahead: Legacy and Vision

Under Lutfur Rahman’s leadership, PCI continues to honor his father’s legacy with dedication and innovation. The company has adopted sustainable production practices and is actively exploring new export markets. As Lutfur puts it, “We still hold on to the principles my father set—quality, integrity, and making ceramics accessible for all. Our goal is not only to serve our customers but also to contribute to the country’s economic and industrial growth.”

Looking to the future, PCI is exploring renewable energy integration, digital production processes, and expanding its footprint into emerging markets in Asia and Africa. As Bangladesh’s ceramic industry gains global prestige, Peoples Ceramic Industries Ltd. remains at its heart—a symbol of dreams forged in clay and fire, shaped by vision, and driven by a commitment to excellence.

Maximizing Waste Utilization in Ceramic Production

PCI is also a leader in sustainable practices. “We actively reclaim ceramic scraps at various stages of production—including the green (unfired), bisque (partially fired), and even the final (glazed and fully fired) stages,” Lutfur explains. “While reclaiming material from fully finished products is more challenging, we still recover about 4 percent of the material, which helps reduce waste and promote sustainability. Additionally, our Effluent Treatment Plant (ETP) operates 24/7, with the recovered China clay fully recycled for reuse in production.”

From Frankfurt to the Factory: A Legacy of Green Commitment

Lutfur recalled a defining moment in 1988 during a visit to Frankfurt, arranged through the Export Promotion Bureau (EPB). “I learned that the European Union was considering a ban on lead and cadmium in decals—a matter particularly important since we sourced our decals from Holland. After discussing this with a knowledgeable German expert, we raised concerns about certification. The British Ceramic Research Institute (BCI) then issued a certificate confirming the safety of our products, which a UK supplier also verified by testing our samples. This process underscored our commitment to sustainability and minimizing environmental hazards. Even today, PCI upholds these environmentally responsible practices, ensuring compliance with global safety standards.”

Shifting Focus from Exports to Dominating the Local Market

“Our value addition exceeds 60 percent, even though we import raw materials from abroad,” Lutfur noted. Historically, PCI sourced clay from Netrokona through a formal government agreement. He observed that while Bangladesh’s ceramic sector faced challenges, China’s domestic availability of raw materials gave it a competitive edge—affording easier access to the EU market. As Bangladesh began losing market share in the early 2000s, PCI shifted its focus to the local market. This strategic move proved successful; today, 90 percent of their production is sold within Bangladesh.

Peoples Ceramic Industries’ story is one of passion, perseverance, and innovation—a journey that continues to shape Bangladesh’s industrial legacy. Whether through sustainable practices or groundbreaking production techniques, PCI remains a shining example of dreams forged in clay and fire, standing firm on a foundation built by vision and integrity.

Photo: Zoha | Courtesy