5TH ISSUE

BUPLISHED BY BCMEA

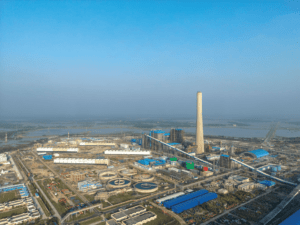

Rampal Coal-fired power plant – A Major Solution to Bangladesh’s Power Crisis

Bangladesh is at an unprecedented crossroads with power crisis and hyper inflation. At a time when major industries at home suffer an acute power crisis, aggravated by the the Russia-Ukraine war following the Covid-19 pandemic, the recent soft inauguration of the first unit of the 1,320-megawatt Maitree Super-Thermal Power Project, also known as Rampal Power Plant, is believed to have been a relief from the energy crisis. Amid the crisis globally, Bangladeshi stakeholders, especially those involved with the multi billion-dollar export industries, manufacturing sector and the financial sector, are now waiting wholeheartedly for commercial operation of the Rampal Power Plant soon to rid the nation of this power predicament. Domestic energy experts and analysts alongside other stakeholders look optimistic with this project and they are of the opinion that the Rampal power project is economically feasible, sustainable and profitable. Terming it one of the cheapest power plants of its kind in the country, they strongly viewed that the plant will get going with the key objective of generating affordable electricity as a resilient and viable solution to the country’s power crisis. Prime Minister Sheikh Hasina and her Indian counterpart Narendra Modi jointly inaugurated the first unit of the coal-fired super-thermal plant through video conferencing on September 6, 2022. The country’s largest power plant is sited on an area of more than 915 acres of land in Rampal upazilla in south-western Bagerhat district under Khulna division, some 272 kilometres away from the capital Dhaka. The high-efficiency, low-emission supercritical plant site sits 14 kilometres north of the world’s largest mangrove forest, the Sundarbans. About the funders The Rampal power project is a joint venture between India’s state-owned National Thermal Power Corporation (NTPC) Ltd and the state-owned Bangladesh Power Development Board (BPDB). The US$ 2.00 billion joint venture company is known as the Bangladesh-India Friendship Power Company Ltd. (BIFPCL) that builds, runs and operates this power facility. The BIFPCL has been co-promoted by the BPDB of Bangladesh and the NTPC Ltd of India with an equal (50:50) equity investment. According to Bangladesh’s power ministry, the joint venture company will enjoy a 15-year tax holiday. In March 2022, Bangladesh boasted the country’s access to 100 per cent electricity, but the national power grid system failed in July and power outage suddenly began to disturb the nation and the socio-economic activities. The Power Division disclosed that the largest amount of what is technically called load-shedding per day stood at 2,000–2,200 MW during the July-September period. But this shortfall peaked in October, taking it to 2,500–3,000 MW. The start of the project BPDB and NTPC entered into a memorandum of understanding (MoU) instrument in 2010 to implementing this mega power plant project in Bagerhat’s Rampal upazilla that has seen an upturn in economic activities centring this power plant in recent years. An estimated 80 per cent of the project costs will be covered through a long-term loan from the EXIM Bank of India. As the construction of the facility was ongoing, the February 2021 was set as the first deadline for commissioning the power plant’s first unit while the second unit by August 2021, according to competent sources. However, the deadline was extended several times for a number of reasons, including emergence of the Covid-19 pandemic in 2020. Use of coal and technology A coal-fired plant produces electricity by burning coal in a boiler to produce steam. Then the steam, produced under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then cooled, condensed back into water and returned to the boiler in order to start the process over. Supercritical combustion technology and sophisticated equipment are being used to lessen environmental hazards and thus make this project safe and eco-friendly. Some 6,500 cubic meters of water will be required per hour and minimum 10,000 tonnes of coal will be required to produce 1300 MW electricity every day. The ash content of this imported Indonesian coal is 8-10%. The height of chimney is 275 meters, equivalent to 90 storied building. In its initial stages, there was a strong debate on the red-hot issue of installing this coal-fuelled thermal power facility near a forest and some termed it suicidal with apprehensions of environmental disaster for the forest, which is home to thousands of wild species, flora and fauna. Some environmentalists made a mass call for scrapping of the project. The government, however, showed its determination to go ahead with the project. State energy experts said the project would not be harmful as its supercritical technology will minimise ecological hazards. Eco-warriors demanded that environmental concerns must be given precedence over commercial interest. They called for doing an environmental impact assessment and feasibility study before embarking on the project that may have anthropogenic impacts on environment, including effects on biophysical environments, biodiversity and other resources, let alone emissions of carbon dioxide and other pollutants as well as particulates. The joint venture company has already planted 116,000 different kinds of trees around the project site while the Centre for Environmental and Geographic Information Services (CEGIS) is monitoring the parameters related to the environment of the Rampal site and its adjacent areas, including Khulna and the Sundarbans. Employment opportunities The Rampal power plant project has opened up a job generation opportunity for local people and those affected for construction of this project’s infrastructure and during its operational period. As this region has long remained underdeveloped, opportunity of trade and employment was very limited. The power plant project has come as a relief to some extent. Alongside direct employment in the BIFPCL, there will be a huge opportunity to the locals for business and other indirect employment prospects. Moreover, this industry will usher in economic growth in Rampal in particular and the country in general, creating many downstream and/or related industries. Supply chain The supply chain of coal in all coal-fired power plants, including the Rampal power plant, is the biggest challenge. Technically unique in the plant is the supply chain issue. The Rampal

Read More

Surging Potential of CBC Tiles: In conversation with Sayma Islam

China-Bangla Ceramic Industries Ltd. (CBC) is one of the top ceramic manufacturer companies, founded in 2001, as a joint venture private sector entity between Bangladesh and China. It produces a wide range of Wall and Floor tiles including Homogeneous, Decor and Border tiles. China-Bangla Ceramic Industries Ltd is well-known company as importer, supplier, distributor, wholesaler, retailer and manufacturer of ceramic and tiles products in Bangladesh. Everyone can depend on CBC Tiles for their commercial office, living room, bedroom, kitchen, bathroom, outdoors and stair. All products are wall and floor tiles, and cladding. Annual production capacity of unit-1 is 7.5 million sq. metre and unit-2 is 3.5 million sq. metre. Its total employees are 1200 now. It has manufacturing plants in Tarabo, Rupganj, Narayanganj (unit 1) and Charmadhobdi, Bhatpara, Panchdona, Narsingdi (unit 2). All its technology and machinery were imported from Italy, Austria and China. The Chairman of the company is Ferdousi Islam, Managing Director Mr. Md. Shirajul Islam Mollah, CEO and Director Sayma Islam. China-Bangla Ceramic Industries Ltd. A top ceramic manufacturer of BD CBC is a well-known competitor and a leading brand. Ceramic Bangladesh recently had the opportunity to sit with Sayma Islam, CEO of CBC, for a delightful tête-à-tête and learned about the insights of CBC, their tested strategies and future plans. What is your leadership philosophy in creating that change? “It’s been 10 years since I’ve joined CBC. I was appointed as a CEO but I didn’t know what that meant at the time. I was at my learning stage and it took me 2-3 years to figure out the role. My father grew the business with his own hands, and when I joined, I wanted to introduce something that would make CBC better. I wanted to set the vision. It’s a full Bangladeshi company now since we have taken over but we kept the name. And as the newer generation I wanted to introduce sustainability. I set the vision for the company and inherited the norms and traditions from my father. But I got out of the norm and visualised how I wanted the company to grow. I changed the logo and gave it a new look. Set up another factory that is capable of manufacturing modern tiles. And we focused on competing with foreign products that were doing well locally. The team took instant decisions and found out ways to catch up with the industry’s unceasing changes. Now that everything is more digitised, the technology sector is going through rapid transformation. Just a couple of years ago, the industry lacked skilled manpower and had to import raw materials. Now we have all the gaps filled. CBC hires foreign experts now who mostly work in the R&D (research and development) department. This is one of their strategies that helped them immensely.” What do you think has been the key to its success? “We are raising the bar every time by looking for better technicians, using better raw materials, and researching more and more. We chased better quality and looked at the market to see what was in demand. We worked on the designs and quality according to that demand. We started CBC and it’s been 20 years plus already. And when we started there wasn’t anything called ceramic tiles. We are the second introducers of foreign tiles substitute. One of our biggest contribution would be that we’ve increased the local demand for locally made ceramic tiles. Now there is a huge variety of tiles and we focus on CRM when it comes to selling ours in the market.” How do you smoothly manage such a sensitive part? “Most of the employees we have, have been with us for a long time. We give two days off and provide a friendly, newly introduced corporate environment. We are paying incentives, we provide support system for a deceased employee’s family and we motivate our employees to gladly work with us with diligence.” Ceramic industries should focus on research. Ms. Sayma said, “The more R&D we do the better this sector will get. If we can maintain quality in production then the finished good will be good as well.We need modern solutions and constantly research for updated product designs.The market is growing but it hasn’t reached saturation point. We are focusing on constant growth. We are also thinking about real estate now that we have developed so much. We already have 3 ongoing projects. Our plan is to branch out with real estate, cement factories, and sanitary ware.” She added, “What keeps me focused is my father. He plays a gigantic role in our upbringing. Fifteen years back, women weren’t on this scene. After my joining we expanded to another factory, and we are working on a third plant.

Read More

The Future of Architecture Lies in the Slab Tiles

Large format tiles are becoming new trend as people prefer large format Slab Tiles. The demand for these tiles, which are several times larger than conventional tiles, is increasing worldwide. The competiting countries of Bangladesh like Vietnam, China and India are grabbing the global markets of slab tiles rapidly. Despite the popularity of slab tiles in the Middle East and European countries, India, China and Vietnam have taken the monopoly of slab tiles’ market. Although the technology started in Italy, it quickly became popular in other countries. The speciality of slab tiles are its large size, very fewer joints, nice to see and high aesthetic value with strength and durability. Since there are fewer joints, it also has less chance of catching dirt. It can be cut as desired and set on the floor or wall. Moreover, slab tiles are much stronger and thicker than normal tiles. Several companies including Akij, DBL, Sheltech, Greatwall and RAK have started manufacturing mini slab tiles in Bangladesh. Only three years ago, slab tiles of 1200cm x 2400cm size were imported from Italy. At that time, the largest size of tiles in Bangladesh was 60cm x 60cm. Now 600cm x 1200cm; 800cm x 800cm and 1000cm x 1000cm size slab tiles are being manufactured in the country. Its size is gradually increasing. Within the next couple of years, various companies will run the process of manufacturing 1200cm x 2400cm size perfect slab tiles in the country. At the one hand, the production cost of slab tiles is lower than the conventional small and medium tiles and on the other hand, its price is relatively high in the market. Companies are more inclined towards these tiles due to market demand. Slab tiles are the new trend in the world tiles market now, because its features and advantages are very attractive and consumer friendly. Wide range of usages: Bathrooms, Kitchens, Countertops, Cabinets, Working tables, Offices, Shopping Malls, Hotels, Restaurants, Community centers and many more places Creating a continuity effect: Due to large size, there is less visibility of tile joint and the effect of tile texture is lively. Reduced installation time :Due to large format the installation time is much easier than traditional tiles. More hygienic & easy to clean : With less joints, there are fewer areas in which dirts can be stored and due to porcelain stoneware, it is itself more hygienic and easier to clean. Benefits of Slab Tiles : Excellent appearance due to the narrow joints ensures a seamless surface and vintage look. Sizes are available from 600cm x 1200cm to 1600cm x 3200cm with 5mm to 14mm thickness. The manufactures can cut this slab tiles as per their desired sizes and shapes. They are suitable for both wall and floor surface. Large format tiles can help enhance the look of the house, working wonderfully well in modern and minimalist houses. Each large wall tile and floor tile covers more square feet than a standard tile, leading to fewer grout lines across floors and walls, more seamless and stylish looks, and easier maintenance. Slab tiles are not themselves a different tile material – only a different manufacturing format. Usually made from porcelain or stone, slab tiles differ from normal tiles only in size. They are much taller and wider, with some variants coming in at a whopping 10-by-5-feet. Slab formats are in demand due to a few advantages that they possess over. normal tiles: chief of them being that they are cheaper and easier to work. There is a huge demand for slab tiles in the Middle East and European countries. At the moment, the demand of Slab Tiles is mostly fulfilled by China and India. Time is not far when this will be done by other Asian countries as well. Mr. Khourshed Alam, Director (Marketing) of Akij Ceramics said if it is not 1200cm x 2400cm, it cannot be called real slab tiles. Akij is now manufacturing tiles in the size of 600cm x 1200cm which are called mini slabs and hopefully by mid of 2023 Akij will produce 1000cm x 1200cm. Moreover, with the new technology that Akij is adding to, it will be possible to produce actual size slab tiles within the next 2/3 years ranging 1200cm-2400cm sizes. Pointing out that these tiles have a huge export market, he said, the world is now rapidly moving out of small tiles. Akij is also targeting huge export markets in Europe and the Middle East. He commented that the market of small and medium tiles in Bangladesh will also shrink soon. Because people are now giving more importance to the aesthetics of slab tiles as it can be cut to any size and fitted. Although there will be a little wastage while cutting these tiles, the beauty makes it all worth it. Besides, thanks to its thickness its durability is higher. Mohammad Bayezed Bashar, GM (Operation) of DBL Ceramics said that the demand for slab tiles has been increasing in the Bangladesh market for the past several years. That is why, various companies are now manufacturing these tiles and adopting the required technology. Its size is also increasing step by step. Currently DBL has started manufacturing tiles of 600cm x 1200cm size. There are plans to make it a size of 1200cm x 2400cm in the next two or three years. But at present, the major obstacle in expanding the market for these tiles is the lack of skilled fitters. That is why, DBL is training fitters across the country. They have helped to create at least 10,000 trained and skilled fitters across the country. It will also increase the income of the fitters. It is expected that as the number of fitters trained to install slab tiles increases, the market for these tiles will also expand rapidly. Mr Bayezed also said that the tiles that are currently being made in Bangladesh are done with “press” technology. But the next upgraded technology is “Roller or Compaction” technology, which will come

Read More

The story Roofing Tiles of a Maker of eco-friendly

Did you know who the manufacturer of eco-friendly roofing tiles in Bangladesh is? He is none other than Farid Hossain who has set a pace in roofing tiles innovation. Having a diploma in ceramics, he had an illustrious career for 10 years between 2006 and 2016. But he got immersed in thought about seeking certain scope to develop entrepreneurship as he never felt comfortable at a job under any employers. Mr Farid Hossain was born and brought up in a village in central Gazipur district adjacent to Dhaka city. He used to dig into different innovative ideas and feats. Now in his 40s, he used to visit his neighbourhood since his boyhood only to see potters busy crafting ancient earthenware round the clock. That craftsmanship interested him in the making of eco-friendly traditional clay products. His inborn passion is imprinted throughout his life and career. After obtaining a higher secondary degree, Mr Farid took a four-year diploma degree in ceramic from Bangladesh Institute of Glass and Ceramics in 2006. Later, he obtained a Bachelor’s degree in electrical and electronic engineering from International University of Business Agriculture and Technology amidst his pursuit of a job. The artisans, who crafted different ancient clay items at his village alongside his long career in the ceramic industry, enthused him greatly to contribute to the growth of the sector as a prolific entrepreneur. Mr Farid, who has a four-member family, has a profound love for soil and he keeps on exploring his passion for the motherland. Mr Farid believes human beings are made of soil and they cannot deny it anyway. So, he always tries to explore the strength of fertile soil. Building up a connection with old-age traditional ceramic items, Mr Farid is poised to reshuffle his plan through expanding his business each year beyond the country and reaching out to people across the globe. His factory now produces an estimated 5,000 units of tiles daily, thus amounting to 750,000 units yearly. His fully eco-friendly products are free from harmful oxide. Although Mr Farid was willing to set himself up as an entrepreneur since his early job career, he could not start it because of an acute shortage of working capital, according to this self-made man. His forefathers had been involved in farming for ages. “So, it was a Herculean task to dream of being an entrepreneur as traditionally and typically most of us in society prefer working under employers as it is regarded as better, secure and protected,” Mr Farid said. Process of Making Roofing Tiles Only soil and silicon oil are the vital components for making tiles. Mr Farid collected soil from his localities and oil from some local importers. There is no dearth of soil in the market. Primarily, he used fuel wood to manufacture tiles. But he now uses a reticulated gas system to halt carbon emissions. Mr Farid, however, seeks piped gas as the existing system is too costly that triggers higher prices of tiles. To get a finished product, Mr Farid first collects suitable soil. Then he does the processing in the production line, including crushing, grinding, screening, moisturising, forming, drying up by a dryer, finishing by kiln and sorting to packing. Mr Farid’s Major Innovations Mr Farid was inquisitive about producing engineering products that also inspired him to develop two vital machines, which are being used to shape roofing tiles at his own factory. He used indigenous technology and locally available equipment to develop them. The machines are cheaper than the imported ones. Through these innovations, Mr Farid has been able to start his business with a paltry capital. Why Market Growing Although roofing tiles are costlier than any traditional rooftop solutions, people are becoming more interested in installing the artistically good-looking system as it keeps houses cosy, cold and comfortable in addition to its heat-proof condition. The system has a deciding effect on the appearance of a building and also shields houses or buildings from rain, noise, wind, fire and hails. Roofing tiles also reduce energy consumption. Local and Foreign Market Expansion In 2017, Mr Farid set up his enterprise with Tk 0. 2 million and 12 workers on a 20 decimal of land after amassing the funds from selling his wife’s ornaments and leasing out his father’s land without taking anything from banks or any state support. After the initial teething trouble, his business has now an outlay of over Tk 30 million with 32 employees working on an acre of land amid Covid-19 fallout and a possible recession mainly caused by the ongoing Russia-Ukraine war. According to Mr Farid, the domestic market could have expanded further with state patronage. Even local entrepreneurs could have grabbed a slice in overseas markets as the global market size is rising fast due to its aesthetic beauty and eco-friendliness. He attributed market growth to multiple state initiatives for infrastructure development in recent times. The global roofing tiles market size was valued at $30,400.0 million in 2019 and it is projected to reach $41,354.9 million by 2027, registering a compound annual growth rate (CAGR) of 5.20 per cent from 2020 to 2027. The market size is growing as the state focus on and public mindset towards eco-friendly household products are shifting fast. Local factories are grabbing nearly 60 per cent of the market, whereas China, India and Vietnam are sharing 40 per cent. Local market leaders include Mirpur Ceramics Limited, Tradexcel Ceramics Limited, and Conforce Ceramic and Refractories Limited. Mr Farid has called upon the government to take effective measures to curb the rising import of roofing tiles and patronise the local industry for the sake of further growth of the nascent ceramic industry.

Read More

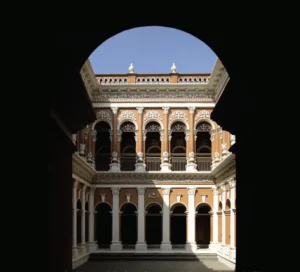

Pursuing Prestige: The Radisson blu water garden

We rarely find a person acquainted with Dhaka who has not heard the name Radisson Blu Dhaka Water Garden or has not seen the iconic pitched roof building on the airport road. For years the name has carried the essence of luxury, exclusivity, and prominence to mass people. Just paying a visit to Radisson is enough to make someone feel special. Since 2006, Radisson Blu Dhaka Water Garden has been a prominent name in the luxury hotel market. The luxury and exclusivity with a touch of nature make it the perfect blend for people who want to experience proper five-star hospitality in Dhaka. Radisson Blu Dhaka Water Garden is between the city center and the airport area, making it easy to locate and access, especially for international travelers, including most of the target group. Being situated away from the urban chaos gives it a spacious room to breathe, making it worth battling through the Dhaka traffic to spend quality time with the city dwellers. The building stands as an icon of a five-star hotel in Dhaka city amidst water bodies and green landscapes. The whole area comprises 7-acre of land, but the building stands only on 2.5 acres, leaving the rest to embrace the natural landscape. It becomes hard to miss due to the fusion of Modernist architecture with the nostalgia of our traditional pitched roof. The project is a partnership between the property owner, Sena Hotel Developments Limited, and the multinational corporation, Radisson Hotel Chains, which provides quality management. International and local consultants worked together to develop the building by the brand criteria. Every element, from service, food, room amenities, comfort, building materials, and local experience to security and safety, is carefully designed to provide guests with a meaningful and unforgettable experience. The grand ramped driveway is one of its kind in this hotel. It is rare to find such a spacious approach in Dhaka due to the congestion and scarcity of land. One can see the unhindered view of the cityscape of Dhaka from the drop-off area, overlooking the wide airport road. After a careful security check, the ceiling height change to the lounge is awestriking. This open salon is visible from all floors above. Its height has been scaled down to human proportions by chandeliers of various sizes and height levels, which creates a more inviting atmosphere. The visual drama of the lounge and its modernist design, circular shape, and strategically placed features give the space an impressive appearance. It provides an interactive space for both the visitors and the occupants. The main entrance is from the first floor, and all the public functions comprise the ground floor and first floor, making it easily accessible without any contact with lift buttons or door handles- which proved to be highly useful during the Covid-19 situation. Radisson Blu Dhaka Water Garden, is one of the prominent names in arranging national and international high official Government and private events, particularly in terms of its security and hospitality. They offer versatile conference rooms that can accommodate up to 1,100 attendees, ensuring the success of events of all sizes covering approximately 3,000 square meters. The Grand Ballroom’s 990 square meters can accommodate a memorable wedding celebration or buffet. The Utshab Banquet Hall is available for product-launching-style events. Several boardrooms are also accessible for personal meetings, training courses, breakout sessions, and other smaller events. Healthy food over taste is a primary priority at Radisson Blu Dhaka Water Garden. The four restaurants and one bar named Blaze Entertainment Lounge & Bar, try to maintain the international standard in every dish. One can enjoy fresh, wholesome Bangladeshi cuisine at ‘Sublime’- a restaurant perfect for a romantic evening or an important client meeting. ‘The Water Garden Brasserie’ can be a perfect option for breakfast, lunch, or dinner, and choose from the international buffet and cook-to-order stations. ‘Spice & Rice’ offers a contemporary twist on Asian food, and ‘Chit Chat’, a deli café, can satisfy the cravings for savory snacks and sweet treats. They also have a dedicated space for smoking called ‘the Cigar bar’. The hotel business is going through a period of transition. The market has been divided into subsets to cater to a wide range of potential clients. Radisson Blu Dhaka Water Garden strives to appeal to locals and tourists by incorporating local cultural elements into its decor and the standard they promise. Radisson Blu Dhaka Water Garden offers accommodation services with its 200 five-star standard hotel rooms and suites. All the rooms have a balcony that offers stunning views of the hotel’s pool, rich landscape, and bustling city streets. In addition, they offer non-smoking floor services for the convenience of their customers. A significant feature of this hotel is the abundance of positive natural light seen throughout. At different times of the day, the play of light and shadow produces contrasting yet complementary effects. The garden, pool, and pond create sublime atmospheric peace. The pond area’s natural splendor lies in the fact that it has been preserved in its original setting, thus enhancing the genuineness and significance of the overall experience. The significance of this pond is enhanced by the jogging path that circles it. The open lounge area next to the pool, surrounded by organized nature, is a beautiful spot to spend some quiet time in the fresh air. The entire garden is planned such that there are always blooms to be seen, no matter the time of year. Radisson Blu Dhaka Water Garden, tries to encourage energy conservation and an eco-friendly environment. They reduce water waste by rainwater harvesting. The hotel promotes low and efficient water and electricity use by creating awareness whenever possible. They utilize as much natural light as possible indoors, given that most of the space is outdoors. The day light-sensitive technology used in light fixtures ensures minimal or no waste of energy. Radisson Blu Dhaka Water Garden promises to provide the best when it comes to service. However, finding skilled human resources who can meet the

Read More

Engr. Md. Faruque Ali How a Ceramic Icon made his Journey

Md. Faruque Ali’s journey is a long and memorable one but it never stops. It’s his journey in the ceramic industry that started in the 1980s – three decades after the inception of ceramics in Bangladesh. He is still a living icon in the sector. Graduating in engineering, Mr. Faruque Ali came to Dhaka in search of a job, and ended up at Power Development Board (PDB). He was posted at Kaptai, Rangamati. It was a lonely job then and two months of service there felt heavier than a decade. So he decided to switch jobs and joined the insulator and sanitary ware industry of Bangladesh Chemical Industries Corporation (BCIC) as an assistant engineer. He worked closely with the production team and his daily routine was to list the machines, know their names, learn how they worked, and how sanitary ware and insulators are produced. Thus came the commencement of Mr. Faruque Ali, now a delightful man with profound experience in the field, who has turned into a true patron of the ceramic industry. In an interview with Ceramic Bangladesh on a Friday morning, he, currently Executive Director at Shinepukur, shared the insights of his journey. Ceramic Bangladesh (CB): Why did you choose the ceramic sector for your career? Faruque Ali (FA): Initially I wasn’t planning to work here. But during my first posting at BCIC, I realised the whole process of production is very amusing. I found it interesting to see how we are producing elegant ceramic products using simply, clay. I instantly fell for the whole process and wanted to remain in the industry. CB: How has your journey been at Shinepukur? FA: I had been in the insulator department for four years. I knew a chemical engineer from the production team there who suggested for the two of us, to join Monno’s new tableware factory. We were in a dilemma when it came to changing from the public sector to the private sector and didn’t think it would be a good idea. So my companion went to join Monno at the time and I did it a bit later. I was there for nine years, took a break for two years and joined Shinepukur afterwards at the end of 1996. I’ve been at Shinepukur for 25 years now. CB: Regarding technological advancement, do you think the industry is moving forward? FA: There are different grades – earthen ware, stone ware, porcelain, and bone china. The modern face of earthen ware is stoneware in the table ware sector. Porcelain and bone china are even better versions. All these products need technological support to come to shape. And the necessary technology was mostly adapted in the European industry and came to us later. Automation came about mainly because we had lack of manpower. But the basics for the body glaze and formula are still the same. Technology has made it all seem much less complicated. For example, imitating the glaze and the formula consistently is remarkably done by the advanced technology we have now. And machine dependency has grown now more than ever. CB: What would you say is the future of the ceramic industry? FA: Ceramic products are a necessity and a fashionable item. The formula of the products is made to be reaction-free and pro-health/safety. When it comes to health, porcelain and bone china are the safest compared to kasha and melamine. Moreover, after 2001 lead and cadmium restrictions have been introduced. These products are the safest because they comply with all the health and safety policies. The future is moving towards similar products. ‘In 22 years of working in the ceramic industry, no two problems I faced were alike. We faced different challenges every day and had to come up with a unique solution for each individual problem we encountered.’ CB: What inspired you to keep going when things got hard? FA: There is a story to best answer this question. Around 2015/16, I worked with a man who said to me ‘In 22 years of working in the ceramic industry, no two problems I faced were alike. We faced different challenges every day and had to come up with a unique solution for each individual problem we encountered.’ My ceramic journey has been likewise. CB: Shinepukur won several export trophies; what is the reason behind Shinepukur’s continuous winning? What are your expectations for Shinepukur’s future? FA: It was the collective effort from everyone, starting from the workers to the top level. And in Shinepukur we are always planning to move forward with our ideas. The team works diligently, and we look for advancement every step of the way. Written by Chisty Rahim

Read More

Developers can offer affordable housing for all, should Govt. allot land : REHAB

Interviewed by Rafikul Islam Alamgir Shamsul Alamin says the UN goal of leaving no one behind won’t be attained if people remain homeless. In view of scarcity in housing facilities in both urban and rural area of Bangladesh, it is quite a complicated task for the government alone to provide housing for all. So, here comes the contribution of the private sector to ensuring affordable housing for all. “We are keen to support the government here but land has to be allotted by developers to facilitate construction for affordable accommodations,” President of Real Estate and Housing Association of Bangladesh (REHAB) Alamgir Shamsul Alamin said in an exclusive interview with Ceramic Bangladesh. The demand for housing is going up in the country as the population is increasing. The country has a vast areas of khas land, which, he argued, can be utilized for building homes at reasonable costs. The REHAB leader insisted that special fund should be created under the national budget to help low-income group of people to own house. Mr Alamgir Shamsul Alamin, serving REHAB for the fourth time as its President, mentioned that since its inception in 1991, the REHAB has been playing an important role in the sector and contributing to economic development. The real estate sector is expanding gradually, thanks to the economic growth under the leadership of Prime Minister Sheikh Hasina, he pointed out, “But we had to deal with many problems in the recent past. The Covid-19, the Russia-Ukraine war, and the price rise of construction materials hit hard the sector. Now we are trying to go ahead overcoming all these challenges,” the REHAB president said. The REHAB has nearly 1,000 members and there is a total of around Tk 1200 billion investment in the sector. “We have 269 linkage industries including rod, cement and ceramic products. Around 4 million people are directly engaged in the sector,” he added. Ceramic Bangladesh (CB): What is your consistent success in integrating and strengthening REHAB? Alamgir Shamsul Alamin : I have been elected the REHAB’s President for the fourth time. I am serving the organisation with reputation. I am also a Director of the Federation of Bangladesh Chambers of Commerce and Industry (FBCCI). After becoming the REHAB President, I have contributed much to the sector, such as reducing registration costs, and legalising undisclosed investments. As the President, I have to maintain a lot of issues of the REHAB. I try to resolve the problems of our sector. I am always thinking about the future of our industry. CB: How did you engage in trade body politics? Alamgir Shamsul Alamin: I wanted to be at the top of domestic trade bodies so that I could influence trade policies/rules. Business is our main goal. Generally the business leaders help policymakers to make policy. If we can’t play role here, we don’t have personal issue. So, we think always to develop organisation and sector as well. Actually it is tough to do business if we can’t bring facility for the sector. If I can contribute here, our business would grow. Besides, I obtained degree from abroad so our thinking is different compared to others. So, our contribution should be counted in economy. In such a context, I engage myself in the trade body politics. CB: What are the current challenges in the real estate sector? Alamgir Shamsul Alamin: Real estate is a big and complex sector. It is a very challenging business in Bangladesh. There are different classes of business in the country. Many segments have different challenges and demands. Like every other sector, there are some good and bad businesses in real estate. Sometimes developers can’t complete projects when clients don’t pay properly. Sometimes projects are not completed due to developers’ negligence. It’s tough to meet all of the challenges. As the leader, I have to take care of these issues. Our problems were at peak after the Covid-19 pandemic made landfall in Bangladesh. Amid the challenges, we managed to save our sector by working together. All had to understand that the situation was not under our control. It was not easy to satisfy customers and developers both. But we did that successfully. Being the REHAB President, I have resolved many of them by discussing them with the government and other stakeholders. Meanwhile, flat prices went up 30 per cent due to price-hike of raw material. And it has impact on our costing. So, prices of apartments go up – 30 per cent a year, which is a big challenge for the real estate sector. After becoming the REHAB president, I have worked hard to contribute as much as I can. All I think about is further development of our sector and its future. CB: Would you please tell us something about the success story of your own business? Alamgir Shamsul Alamin : Now, I am engaged in multiple businesses. Actually, I entered into business through my family hand. I was born in a family of businessmen. My father was a well-known businessman back in the Pakistan days. So, I always dreamt of becoming a businessman. Jute, tea, leather, textiles, and transportation were our primary business. We got into the real estate business in 1995. During my student years, I became involved in politics. I studied in several countries, including Scotland, the United Kingdom, and the United States. On completion of my education, I returned home. And, I maintained the family business by expanding and diversifying. Our business has grown 10 times. I want to ensure further growth in future. Now, I plan for a new joint venture investment of Tk 10 billion in the IT sector. CB: What are the current projects of Shamsul Alamin Real Estate Limited (SARE)? Alamgir Shamsul Alamin: The SARE is a sister concern of Shamsul Alamin Group. I am Managing Director of the company. We have a good number of projects which are ongoing at different sites of Dhaka. Our ongoing projects are Alamin Tonmoy at Baridhara Diplomatic Zone; Alamin Angur at

Read More

NSDA wants to enhance Private Sector Engagement in meeting 4IR Challenges

Creating skilled human resources is the key vision of National Skills Development Authority (NSDA). Aiming to train up 86,13,000 people by the next five years, the authority has adopted the National Action Plan for 2022-27 approved by the governing board meeting on July 31, 2022. “So, my aim is to assist implementation of the vision and mandate of the NSDA to achieve the goal of a developed and prosperous Bangladesh by 2041 declared by Honorable Prime Minister Sheikh Hasina,” the NSDA Executive Chairman Mrs. Nasreen Afroz said in an exclusive interview. Ceramic Bangladesh (CB): Despite a huge demographic dividend, Bangladesh lacks skilled manpower. On the verge of the fourth industrial revolution (4IR), what does NSDA think to move forward? Nasreen Afroz (NA): The NSDA has already prepared more than 35 CS’ on ICT-related courses. We are incorporating 4IR into its curriculum gradually. In addition to that, NSDA will adopt some measures like identify and assess the skill requirements, develop a digitised skills database, incorporate ICT-related skills into the training courses, upgrade the digital skills and knowledge of the instructors, building capacity of the Skills Training Provider (STP) institutes to deliver training on digital and emerging technologies, online training, use of digital technologies for monitoring and assessing performance of STPs and tracking of graduates. CB: How is NSDA focusing on expanding domestic and foreign training opportunities? Do you plan to create opportunities for exports to developed countries? NA: NSDA is working on creating manpower export opportunities to developed countries. For this, we have already received technical guidance from the European Union Delegation which included the qualifications and skills recognition issues between Bangladesh and the EU in different angles. We hope we’ll succeed to set common, simplified rules for all professionals through the agreement, and thus eliminate the inconsistencies inherent to qualifications recognition processes between Bangladesh and EU countries. We’ll create export opportunities in developed countries. CB: Bangladesh has to hire a lot of foreign skilled people to meet the industry demand. How is NSDA working to reduce shortage of skilled manpower here? NA: The NSDA has adopted National Skills Development Policy-2021 and National Action Plan 2022-27. We have a huge demographic dividend that’s good. But, now we need to train them up to the mark matching to the demand in industries in the country. NSDA has almost 350 registered STP institutes. We develop and update curriculum for STPs. After course accreditation when training started we monitor training and conduct assessment neutrally and impartially. We emphasize quality training and quality assessment. So, the trainees are qualified once they are certified by NSDA. The young workforce thus will be skilled and ready for the industries. Thus NSDA is working to reduce shortage of skilled manpower. CB: What are the 5-year plans of NSDA to improve workforce growth, management and development? NA: The NSDA has adopted 5-year National Action Plan 2022-27 approved by the governing board meeting on July 31, 2022. There are some other ministries/ divisions/ agencies that are involved in that action plan where there are some specific targets to achieve. However, the number of total targeted trainees is 86,13,004. Of them, 49,38,870 are under fresh skilling; 9,48,925 under re-skilling; 6,44,485 under up-skilling; 10,83,785 under apprenticeship; 3,43,383 under recognition of prior learning (RPL); and 6,53,556 under entrepreneurship. CB: How does NSDA want to increase involvement of the trainees? What are the prime criteria of the trainees to engage in the training process? NA: I always believe that skills development is a shared responsibility among a number of actors playing their respective roles towards a well-functioning national skill system. The actors include NSDA, various government ministries and departments delivering skills training, public sector training providers, private sector training providers and not-for-profit or NGO training providers, ISCs, trade bodies and employers and employees associations. We want to increase involvement of the trainees through these actors. The prime criteria of the trainees to engage in the training process are passion for technical education, devotion to learn new skills, well–constructed ideas and learning capacity. There is no such barrier like age, prior learning, prior institutional recognition etc. CB: How is NSDA working to meet organisational goals for the betterment of workforce? NA: We are making competency standard and other learning materials for skills training to meet organisational goals. We also register training institutes to conduct training on the basis of those learning materials. Then NSDA conducts assessment impartially by third party assessors and provides certificate to the trainees. Besides, the NSDA formulates skills policy and action plan, strategies and guidelines; forecast demand of skilled labour in domestic as well as overseas job market; identify skills gap; raise awareness on skills training and establishing mutual recognition agreement with destination countries for the migrant skilled workers etc. Basically it is making the youth and marginal people ready as workforce through an effective skills development system. CB: How does NSDA assist the skill development programmes at the national level? NA: NSDA has developed ‘National Skills Portal’ (NSP) offering all its services through online with an aim to collect, organise, analyse and publish data systematically related to skills ecosystem of the country. We want to support the training agencies with competency-based training curriculum and with other technical assistance whereever required. In terms of capacity development, NSDA wants to support training agencies and ISCs with financial assistance from various government funds like NHRDF or any other project if available. CB: How does NSDA want to channelise focusing on academic or institutional support? NA: Through NSP, NSDA is offering all its services online and thus increasing effectiveness, transparency and accountability. Though NSDA focuses on institutional support, as we have our new workforce, we’ll try to focus on academic part as well through them. CB: For the ceramic industry, what kind of skill development programmes will you suggest? NA: I will suggest for technical skills enhancement programme; Reasoning; Analytical and Problem-solving skill enhancement programme; Trending Technology; and Interpersonal skills-related programme. CB: What is the way to develop up-skill management that can provide

Read More

The Journey of Ceramics in Bangladesh

The origin of pottery in Bangladesh dates back to the later or post Mohenjo-daro and Harappa civilization and to the Indo-Aryan Vedic age, according to the research on ceramic earthenware and artifacts found after excavation of the ruins in Mahasthangarh of Bogura and Wari-Bateshwar in Narsingdi. Discoveries in Wari-Bateshwar included two millennium old potteries and terracotta. The potters then used traditional methods to make water vessels and sculptures for worshipping and as household utensils and showpieces. In the medieval age, the potters were popularised by the Hindu and Buddhist rulers and zamindars when they used to make statues of gods and goddesses, Buddha, plates, other aesthetical items and terracotta plaques in the temples and monasteries. The potters made everyday household items for sale in the local markets to earn a living. In the past century, the white clay deposits were first found in Mymensingh, Sylhet and Netrokona, the largest of which was discovered at Bijoypur of Mymensingh in 1957. Since the discovery of the white clay reserves in Bangladesh, the ceramic industry has come a long way. ‘Ceramic’ comes from the Greek word meaning ‘Pottery’. The journey of ceramics started through pottery and was initially only a mixture of inorganic, non-metallic clay which could be heated at very high temperature to make it hold its shape. Since then, mankind has found multifarious uses for this clay and the quality of the clay has been improved. Ceramic in this era has much hardness and strength, is heat resistant, is a good insulator, unreactive to other chemicals and long-lasting and hard-wearing. Among its many uses, the ceramics industry started in Bangladesh with just the manufacture of tableware and now covers four broad subsectors: Tableware, Tiles, Sanitary ware and Ceramic Bricks. A brief review of the journey of ceramics in Bangladesh is portrayed below. In 1959 the industry took its nascent steps with only one small tableware manufacturing plant in Bogura, Tajma Ceramic Industries Ltd. Tajma Ceramics is the first ceramic earthenware plant to produce porcelain tableware using traditional methods. In 1962, Mirpur Ceramic Works Ltd in Dhaka started to produce heavy clay products using German plant and technology and developed a reputation of manufacturing best quality ceramic bricks in the subcontinent. In 1966, Peoples Ceramic Industries Ltd, formerly known as Pakistan Ceramic Industries, located in Tongi, Gazipur, started production using modern porcelain tableware manufacturing technology procured from Japan. They started exporting their products In 1974, the country’s first non-heavy clay building ceramic plant came on the stream, Dacca Ceramic & Sanitary-wares Ltd. The company was the first to start production of sanitary ware at Tongi, Gazipur. In 1985, Monno Ceramic Industries Ltd transformed and revolutionised the exports of local ceramic products by branding Bangladesh ceramic products on an international level, using West European and Japanese plants and machinery. Monno Ceramic is the first industry to use ultra-modern technologies to produce porcelain tableware aimed at exporting worldwide. Later it added its bone china tableware unit also aimed at improving the exports of ceramic tableware from Bangladesh. In 1986, Bangladesh Insulator & Sanitary ware Factory Ltd. (BISF) started manufacture of ceramic tiles at Mirpur, Dhaka, with Czech machinery and technology. In the same year, Bengal Fine Ceramics Ltd, the first stoneware tableware manufacturer in Bangladesh, located in Dhaka, entered the domestic and international markets. In 1992, with the exponentially growing ceramic industry, a nationally recognised trade organisation of manufacturers and exporters of ceramic tableware, pottery, tiles, sanitary ware, insulator and other ceramic products was formed, called Bangladesh Ceramic Manufacturers & Exporters Association (BCMEA) In 1993, Madhumati Tiles Ltd. became the country’s first tile manufacturer to use modern German and Italian technologies to produce the latest standard ceramic tiles that domestic consumers see and use at present. In 1999, Shinepukur Ceramics Ltd. started production of porcelain and bone china tableware with Japanese, German and French machinery and technology. It earned a reputation for being one of the major exporters in Asia. Ceramic Industry Scenario (FY 2021-22) An industrial revolution has resulted in a burgeoning Ceramic Industry since the start of its journey with just one small tableware manufacturing plant. Today, there are more than 70 ceramic manufacturers in operation in the country with core products being tiles, tableware, sanitary ware and bricks. As the country experiences steady economic growth and urbanisation, the local demand for ceramic products too continues to grow. These ceramic bricks, tiles and sanitary ware have been used in several mega projects by the government to ensure overall infrastructural development. The growth trend is an indication of the industry’s potential to be one of the top foreign exchange earners. And the tableware made in Bangladesh, both Bone China and Porcelain, is famous around the world for its eminent quality and design. Here is a snapshot of Bangladesh’s ceramic industry: Quality Raw Materials: The exponential growth in the ceramic sector is owing to the high-quality ceramic products manufactured in Bangladesh. The ceramic sector has the availability of uninterrupted Sulphur-free natural gas and the latest cutting-edge technologies imported from Germany, which make our products shinier and more durable. The glaze and pigments are lead and cadmium-free and 100 per cent halal ingredients are used in the production process. The other factor in favour of the industry flourishing is the relatively low labour cost yet availability of skilled manpower. The direct manpower involvement in the industry is about 52,000 whilst the indirect involvement is over half a million. The industry is considerably compassionate towards the women and people with disability. The industry works to train women and physically challenged workers for inclusivity. Around 20 per cent of the workforce is highly-skilled women. Today owing to these favourable conditions, the industry is distinguished around the world. Investment: The total investment, both local and international, in the industry is about US$ 1.70 billion. The investment share of tiles is 62 per cent, tableware 23 per cent and sanitary ware 15 per cent. The sector has lured foreign investment mainly from China and the Middle East. These

Read More

Bangladesh a huge investment potential in ceramic sector

With the growing demand for different type of ceramic products in local and international markets, investors are leaning towards big investment in the industry that has a huge potential. Since 1995, six foreign companies have jointly invested worth Tk 1950.07 crore in Bangladesh’s ceramic sector. Production of the ceramic items grew 200 per cent in the past 10 years. However, there is a total investment of around $ 1.70 billion in the country. Industry insiders said nowadays the demand for ceramic tableware, pottery, tiles, sanitary ware, insulators and others products got popular, thanks to changing taste and lifestyle of people. Once people wanted to construct only a simple building but now they try to add materials like tiles. These products are now used in residential and commercial buildings, mosques, educational institutions and hospitals. Foreign investment rising gradually Foreign companies are keen to invest in the sector. So, the industry is awaiting huge investment, thanks to the government’s policy support, and availability of low cost labour. Fu-wang Ceramic industry Ltd, RAK Ceramics (BD) Ltd, BHL Ceramic Co. Ltd, Star Porcelain Ltd, South East Union Ceramic Ind. Ltd, and Sun Power Ceramics Co. Ltd have already invested in joint venture projects in Bangladesh. Most of companies came from China and the UAE that invested in Gazipur, Habiganj and Khulna. Ceramic tableware, tiles and sanitary ware are being produced by these companies, according to Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA). Talking to this scribe, RAK Ceramics Company Secretary Muhammad Shahidul Islam said the ceramic products are being used in residential and commercial buildings, mosques, educational institutions and hospitals. Now the items turned as essential products. “Most of our buyers are middle and upper middle class people. We produce over 1,000 types of products including high valued ones. There is no difference between our manufactured products and imported ones considering quality but we sell our products at 20-30 percent less,” he said Why is the ceramic sector perfect for investment? Bangladesh is one of the fastest growing economies in the world that has a big domestic market of around 163.8 million people. Cheap labour, skilled manpower, government policy support, political stability and perfect geographical position for producing and supplying all ceramics products made it an attractive sector for investment. BCMEA findings say that the ceramic sector offers a good number of facilities including lead and cadmium-free glaze as well as pigments; Sulfur-free natural gas supply; and flexibility in minimum order quantity. Capable of exporting bulk quantity, Bangladesh also enjoys GSP (Generalised System of Preference) facilities for exporting ceramic products. Now Bangladesh is exporting the ceramic products to more than 50 countries including the USA, Canada, the UK, Germany, France, Italy, Sweden, Switzerland, Norway, Greece, Ireland, the Netherlands, Spain, Austria, Australia, New Zealand, Japan, Russian, the UAE, Saudi Arabia, Kuwait, Egypt, Turkey, India, Pakistan, Singapore, and Brazil. BCMEA President Md. Shirajul Islam Mollah said the ceramic is an emerging sector. Bangladesh is an investment-friendly country for foreign investors so, he added, the ceramic sector has a bright prospect. Domestic ceramic market booming The country’s first ceramic factory named Tajma Ceramic Industries was established in Bogura in 1958 for manufacturing porcelain tableware. Primarily, the small company started with 3-4 types of cups but now the factory produces around 70 types of tableware. Later, Pakistan Ceramic Industries (now Peoples Ceramic Industries) started production in 1962. Monno Ceramics was established in 1985, Bengal Fine Ceramics in 1986 and Shinepukur Ceramics in 1997. Foreign investment came to this sector in Bangladesh through Fu-Wang Ceramic Industry Limited in 1995. RAK Ceramics was incorporated in 1998 and its commercial production started in 2000. BCMEA data showed that the demand for ceramic products increased at least 22 per cent in the last five years. However, a total of 71 companies invested Tk 15,356.50 crore in 2021-22 f iscal year. Of them, 20 tableware companies invested Tk 3,174.25 while 33 tiles companies invested Tk 10,151.86 crore and 18 sanitary ware companies invested Tk 2,030.39 crore. The country earned Tk 385.21 crore through export during the period. It gave revenue to the exchequer amounting to Tk 3500 crore. Value addition was 65 per cent. More than 500,000 people are directly and indirectly involved in the sector. Its production growth increased 200 per cent in last 10 years. According to a report of the business research company, the global ceramics market went up $114.11 billion in 2022 which was $107.72 billion the previous year. The company also projected that the global ceramics market size would reach $145.93 billion in 2026 at a compound annual growth rate of 6.34 per cent. Industrial Challenges There are some temporarily problems including gas supply in the country. Policymakers said these will be resolved soon. The BCMEA president said there is a gas crisis in the industry that was triggered by the Russia-Ukraine war. Bangladesh can attract more foreign investment in the ceramic sector ensuring an uninterrupted supply of gas and electricity. “Besides, we need a 20 per cent cash incentive, instead of the present 10 per cent, on the export of all types of ceramic products to boost the sector further,” he pointed out Ceramic Expo Bangladesh 2022 BCMEA is going to organize a three-day-long biggest international exhibition at International Convention City Bashundhara (ICCB) in Dhaka on November 24-26 to bring local and international manufacturers, exporters and suppliers of ceramics into a single platform. The RAK Ceramics Company’s secretary said, “The exhibition is a better place to promote a company’s products. So, we will take part in the ceramic expo to market our products.” BCMEA President Mr. Md. Shirajul Islam Mollah stated that the exhibition is expected to be attended by representatives of more than 300 global brands, manufacturers and suppliers of ceramic raw materials and machineries from 20 countries. “The expo will create ample scope for foreign ceramic manufacturers, buyers and investors to explore and invest in the emerging ceramic industry of Bangladesh,” he added Written by Rafikul Islam

Read More

Becoming one with a Clay

You perhaps didn’t think you could come closer to clay in this crowded and bustling city of Dhaka in a manner that is both therapeutic and entertaining at the same time. However, there is a cozy little pottery studio hidden away on the periphery of Dhaka city, for you to escape to and rejoice in the fluidity of clay. Clay Station Dhaka, the pottery studio, which is a brainchild of Sharmin Ahmed and Co-founded by Sayeed Chowdhury, is a gift to Dhaka dwelers in the form of a healthier entertainment choice. Growing up, we had many outdoor entertainment options like going cycling, playing, venturing into adventures with comrades, but then our options are condensed into just being restaurants, cafes or a screen at home. Clay station emerged from the unfulfilled need of a creative source of amusement or even distraction of the good kind. From traveling around the world, both Ms Sharmin and Mr Sayeed experienced the abundance of recreational activities, to choose from, in the developed countries. In contrast to which they felt a stark lack of recreational choices would aid in unveiling one’s creativity or imagination, here in Dhaka. The founders stumbled upon the idea while visiting a pottery studio in the United States of America, where they laid witness to the magical property of clay in bringing people of all ages, gender, race or ability together in a fun and engaging way. Ms Sharmin recalls a couple in their 60s on a blind date getting to know each other through an engaging pottery painting session. She says, “Pottery could be a great choice for ice-breaking. It is calming yet it could be interactive too.” Neither being from the Ceramics background, they embarked upon this testing journey of creating a platform for the youth of Dhaka city, to indulge in creative activities that resonate with nature. The two spotted an untapped potential in the entertainment industry in Bangladesh which led them to put their business acumen and professional experience into play to build the pottery studio. They gathered ceramic graduates from Charukola and Santiniketan, India to provide and guide the patrons with the services and products they offer today. Being the pioneer in setting up a pottery studio in Dhaka, they both had to face numerous challenges. There being no pre-existing market for pottery meant sourcing for the ingredients and machines was difficult. They learnt that even the most basic of pottery ingredients like the china clay cannot be found in the local market and using the red clay found in abundance at the riverbanks would reduce the functionality as they could not be painted on or put under high temperature. So they started to source the imported clay from local suppliers and the ceramic glaze for tableware is imported from the USA, the UK or India as it is not available here in a safe composition and contains lead which can lead to lead poisoning. The wheels are imported from Japan, as these automated Japanese pottery wheels are more user-friendly and convenient. They also started to procure porcelain clay from a leading ceramics manufacturing company, Artisan Ceramics Ltd., to make the small keepsakes to paint on at the studio. Clay Station was created to offer cherished and memorable experiences to its patrons. And they wanted to ensure the experience would be the safest they could offer. But as a result of having to import the ingredients in use, the price of the sessions with clay at the studio goes up. Ms Sharmin says, “We wanted to create the safest environment for people to come and indulge in our services. And while ensuring the safety of our patrons and the sustainability of Clay Station, we have to keep the pricing as is and work to create awareness among the people of the therapeutic properties of clay.” “The inspiration to keep pushing forward with Clay Station, honestly, comes from our patrons. They are so appreciative of our initiative that we feel very hopeful about the work we’re doing and get the courage to take it further” Clay Station’s studio was initially located at the heart of Banani, over by the picturesque lake to complement the beautiful experience as a whole. Since then, the studio location has changed but without compromising on the experience. Ms Sharmin adds, “A pottery studio I believe should be closer to nature to enhance the whole experience.” Today, the studio is located at Chef’s Table Courtside which ensures a closeness to nature and also a family-friendly environment. Sunlight pours into this tranquil studio through the big glass windows. And as you look outside you discover yourself surrounded by greenery and the vast blue sky. And to preserve the authenticity of the studio, no plans of opening new branches are on the horizon. But instead, to make pottery more popular, small franchises at different offices or schools could be seen in the future. Even though the target audience were the youth, it was later found out that families with young children responded really well to the captivating activities that went on at the studio. Their three services, Pick and Paint, Pay with Clay and Throw at Wheel are innovative and a great way to relax, learn and explore. It is loved by the parents as it is so rare to find fun activities to do with kids. For Pick and Paint you pick one the cutest pre-made bisques from a range of shapes of a unicorn, puppy, airplane, cactus, and rainbows among many more and paint them in the brightest of colours and your imagination. It’s such a fun and creative activity for children and adults who want to feel young too. Play with Clay will allow you to get creative with a soft doughy clay ball and bring your imagination to life. You can follow your heart and see where that takes you. Chances are, you’ll end up with a meaningful keepsake of your own design which you can later in a week, come

Read More

Delineating Palpable Dreams

Have you ever wondered who usually designs these beautiful buildings while crossing roads? The term architecture might not yet be practiced frequently in our society, but the changing skyline in a few parts of the city shows how architects are being acknowledged in recent years. Years back, it was mostly the peers of architects who knew about them or offered works and planned to get their building designed by an architect. People are more concerned and aware of better designs and well-functioning buildings nowadays. The dreams of architects to be in the business have somewhat taken shape. One of those dreamers is architect Mohammad Foyez Ullah, Principal and Managing Director of Volumezero-Spacezero Ltd.\ Since school times, Foyez Ullah was associated with extracurricular activities alongside studies. After completing school, he joined a cadet college, where he experienced a lot more opportunities. He was overwhelmed by the capacity of being engaged in multi-disciplinary activities and the doors they open. Performing many leadership opportunities encouraged him to be more confident and made him a better learner. He admired and idolized ex-students who topped the tire and studied architecture. The glamour of studying architecture fancied him since then, and he made his deliberate decision. He dropped biology and took a unique subject, Technical drawing, and a workshop under the industrial works to skill himself up before getting into the architectural arena. Drawing the sleek buildings out of concretes, Foyez prefers himself to be a master builder. He happily accepts to be a mason master rather than called an architect. Enjoying his work and learning more from the construction sites satisfies him more. Belongingness to the practice has made him more sensitive toward his colleagues and co-workers. A proper studio culture, where the architects collaborate, has always been his top priority. He mostly believes in investing in making a better working environment for the next generation of practicing peers and setting an example. A structured professional practice, where a career path exists, is rarely practiced in the architectural field. Looking over the benefits and well-being of the employees have mostly lacked behind. But in Volumezero, the architects tend to stick around for a longer period of time. “I have colleagues who have been working with me since the very early of this firm. They hardly shift jobs. The people who left were mostly moving abroad for higher studies. A few countable ones started their own practice. Only self-growth never seems sustainable to me. I want my fellow architects who work alongside me to be in a better state of health and mind through their working experience. We have a proper HR development with many employee benefits besides salary, and constantly try to improve over time,” shared Foyez. The overall system of the filter process of becoming a professional practicing architect has become hard. Hence the quality of the built environment is improving. The architects are better aware of the rules and regulations of the construction laws. Architecture being a sensitive discipline does not only deal with external beauty that we admire. A building is only sustainable when its usability aspects are taken care of properly. The satisfaction and well-being of the user should be the primary concern, as also the neighborhood of the associated building. With the collective responsibility that the profession owns, it should be a trustworthy practice. “Praising architecture is not a contribution to the mass people. The social impact and acknowledgment are very recent. That is because of how we individually pull it up from each end. Our focus should be as a part of society because randomly designing private projects never have any mass impact or societal improvement. Architects add value and contribute to the culture. If we explore our practices and mingle with a community of other practices, our perspective of thinking gets mended and shaped in better ways. Being social helps to be a better professional in terms of different benefits,” explained Foyez. Starting his early career as an academician, he always wanted to be a full-time practicing architect and left academia in 1998. His practice is a design and makes studio. At times they construct a few exclusive projects, and for a few, they go with the development model. This process has empowered the studio and the collaborating architects. They get the chance to visit the construction sites and learn better. The improvement is also excelling because of the era of the information age. The learning process is easy, and professionals keep themselves updated. The ones who are eager and enthusiastic to learn and develop more skills are progressing. “The upcoming generation has a lot of potential and can perform better than us if the talents get tapped correctly. Family support and upbringing are essential parts of this process of grooming. But I believe these new young lives have belongingness to Bangladesh, which is very inspiring. Big opportunities are waiting for them for a very bright future ahead. If you think I am living in a dream, I happily agree to that,” he added very hopefully. “Lead as an example” is the phase that merges with Foyez Ullah in aspects of his professional practices. His thinking process is to live by what he is preaching, and the appreciations from his fellow colleagues and externals encourage him to move forward with this motto and even get better as time goes on. To him, open-mindedness and acceptance are important as dynamics of an architect because architects depend on both critical thinking and execution. Architecture can be a noble profession to many. A lot of architects tend to judge architecture of a city, even if the city is in peril. He is more concerned with “the city as the architecture rather than the architecture of the city” Authored by Rehnuma Tasnim Sheefa

Read More

Symbolizing the elements of space and time

Son of an engineer, but never performed satisfactorily in mathematics. The journey of artist Alak Roy to the Institute of Fine Art, University of Dhaka, was somewhat for that reason. Though it was in a family legacy as his father’s cousins’ studied in the Government Collage of Arts a n d Crafts in Kolkata, West Bengal. He was never an amateur practitioner, but from a very young age, he admired and appreciated artworks. According to him, his luck has always been favored in any way or another; starting with getting scholarships from the very first year to exhibiting works and attending residencies in different countries along with many other internationally renowned artists. The boost to his confidence and self-esteem started when he achieved his very first full free scholarship, which inspired him to look forward to working hard and better. As he used to admire paintings, he took the subject as a major. The scholarship provided the opportunity to learn in India. The guidance of an amazing teacher, who used to work with clay and ceramics, inspired him too. He grew interested to express Bengali culture through murals and reliefs. “We artists who were fresh graduates right after the independence had always wanted to establish the deep culture and belongingness of Bangladesh in our works. It mainly started in the year 1969 and is a milestone in the history as it might be called a cultural revolution of Bangladesh. The country got its self-identification which made us different from Pakistan. Something which we Bengalis are always proud about” shared Alak Roy. They contributed in different ways to being a student at that time, by writing posters late at night, which helped him to improve his handwriting skills, and was very much active in various activities of the liberation movement. He has been influenced by many local works of artists like Kamrul Hasan, Joynul Abedin, and S. M. Sultan, and how they expressed the folklore and culture in their works. That was not an era of the internet, hence exposure to international works or platforms was very limited. Alak Roy found joy in working with clay and ceramics with inner satisfaction. “People have hidden talents and aptitudes. But most fail to realize or explore that side. Hence keeping the world out of their abilities and their self-belongingness,” he added. His courage in working with clay increased gradually exploring different opportunities while observing potters’ work and witnessing multiple terracotta temples in Bishnupur, Bankura, West Bengal, and also in Moynamoti Shalbon Bihar and Cumilla. His first relief exhibition was named “Matir Kana”, and ‘Aboddho’ another high relief work exhibition was also organized. Gradually started progressing with three-dimensional work. He believed in stepping up and not jumping to risks. He always believed that soft clay has a character of its own and there is a lot of potentials to express through this material in form of artwork. He thought of working with clay and ceramic because his native country itself is made of fertile soil which relates him to Bangladesh. People have hidden talents and aptitudes. But most fail to realize or explore that side. Hence keeping the world out of their abilities and their self- belongingness. Being a university teacher, he had his earning source fixed. Sculptors throughout the world are very less in number because their works are not being bought and their setups are costly. He is no different, but this never kept him from producing beautiful sculptures and working for them. There is his early time work in the national museum, a very expressive one. Winning many awards international exposures encouraged him to think bigger and better, to take risks to keep going forward. As he studied murals which in basic terms are artwork related to architecture, that helped him to be liked by architects as well. “I try developing my own clay. I never thought of working with any synthetic materials. I wanted to explore organic materials as it goes with my personality. I also worked with stones and bronze on international platforms, with their help and support. Being a sculptor needs its own form of support and setup. I always spent my earnings developing my working setup to keep improving. For me, my representation was always through my work. As I did not study ceramics, I know little about it. If it was my field of study I might have achieved differently,” shared Alak Roy. His works had been collected by Fukuoka Asian Art Museum. At the Museum of Modern Ceramic Art in Gifu, Japan, 85 sculptors were invited to exhibit, and he was one of them. Similar work was also exhibited at Incheon Centre in South Korea. He did many works and residencies in China, Vietnam, South Korea, America, and many other countries. His last solo exhibition was in France. And did many successful exhibitions in Bangladesh as well. According to him, his biggest achievement is the chance to explore and observe a lot of different artworks and get to meet different artists. While starting his professional practice his first big exposure was doing a sculpture for the Grameen Bank. Worked for the Bangladesh Army as well, initially with the condition of getting the freedom to express himself through his work even sacrificing the negligible honorarium. Personally designed random sculpture gardens as well. Many people complain about the drawbacks of being an academic, but he enjoys learning from young minds, their positive vibes provide active energy to him. There’s a lot of scope in modern art. In his early works, there were many full figures of humans, but later he started concentrating on faces, as the symbolization of more simplified and concentrated human expressions. From facial emotions to more detailed expressions are portrayed in his artworks which are symbols of eyes. “There are a lot of eyes in my works, as me being a visual artist, and we see with eyes. But we all see very differently with our subconscious mind. It’s the matter of perspective

Read More

Prologue to Paerns Emerald Bakery and Cafe