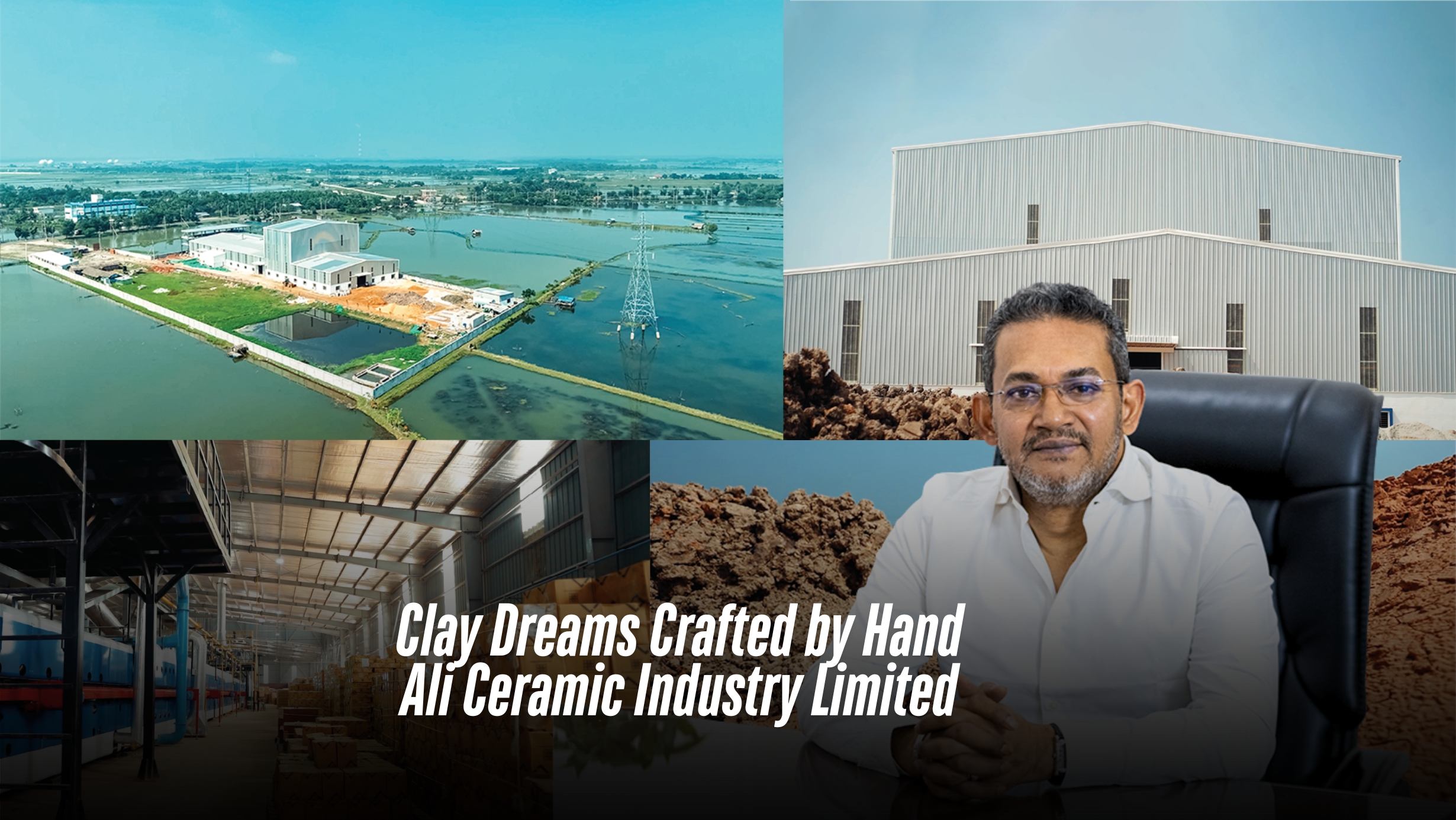

Mir Ceramic Limited (MCL) is one of the largest, prominent ceramic and porcelain tile manufacturers in Bangladesh. The most trusted tiles manufacturer was founded in 2001 and began commercial production in 2002 with the globally acclaimed Italian brand SACMI’s state-of-the-art machinery, widely acknowledged as the best ceramics manufacturing equipment provider in the world. Mir Ceramic is a proud member of Mir Group of Companies, one of the oldest and highly reputed conglomerates in Bangladesh. The Group began its journey in 1968 as Mir Akhter Hossain Limited (MAH), the iconic construction company in Bangladesh. The group has diversified into real estate, banking, telecommunications and ICT industries.

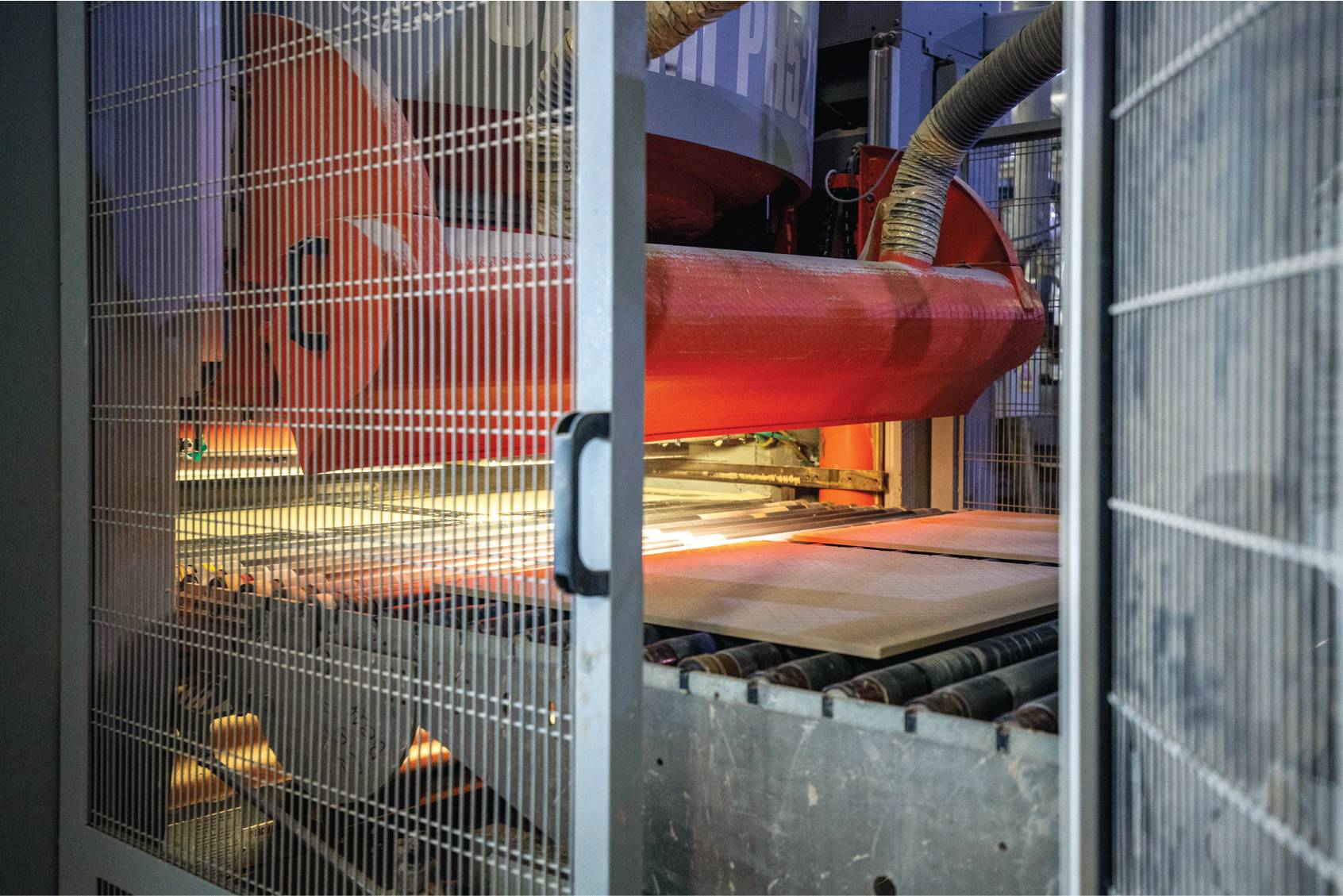

Mir Ceramic produces a range of high-quality products such as porcelain tiles, ceramic wall tiles, granite floor tiles, homogenous stair tiles, and industrial tiles. One of their most popular products is the Mir polished tiles, which are renowned for their exceptional durability and smooth finishing. It has a production capacity of 90,000 square meters of tiles per month.

Proudly promoting ‘Made in Bangladesh’ with a combined workforce of 2,000 local craftsmen and artisans for manufacturing. Mir Ceramic Ltd prides itself on its commitment to quality and customer satisfaction. With a team of experienced professionals and the latest technology, they strive to deliver the best possible products to the customers. The company is constantly innovating and expanding its product line to meet the changing needs of the market.

Skilled Manpower, Innovation, World-Class Machinery and Raw Materials are behind the Success

As one of the leading ceramic and porcelain tile manufacturers, Mir Ceramic Ltd has established a strong reputation for excellence in the industry. Its products are highly sought after by builders, architects, and homeowners alike, who appreciate the quality, durability, and style that the company delivers. Mir secures the highest quality raw materials from across the world, including Spain, Italy, Malaysia and Thailand.

MCL has assembled an expert production team, with decades of experience in the industry, to oversee manufacturing. As a result, Mir Ceramic produces tiles with the highest bending strength and lowest water absorption in Bangladesh. Consistently producing superior quality tiles for over so many years has helped establish Mir as a dominant player in the upscale tiles market in Bangladesh.

Mir Ceramic’s vision is to create a world where those who won’t settle for anything but the best can proudly use tiles made right here in Bangladesh. MCL is committed to producing the strongest and longest lasting tiles in the country by continually adopting the latest manufacturing technology and sourcing the very best raw materials from around the globe.

MCL takes a customer centric approach to product development, by continually engaging customers and technology partners to develop products that meet the evolving needs of the discerning clients. MCL aims to achieve growth while continuing to be environmentally responsible. To achieve this, the company continually leverage the latest technologies to increase the efficiency of manufacturing and energy generation processes and captures and reuses energy, waste raw materials and water.

Manifold regulations are key hurdle f or local and foreign investors “Once the use of ceramic products in Bangladesh was comparatively low. This was due to low purchasing power of people and high cost of ceramics products at the time. Earlier, the country was heavily dependent on imports spending huge amounts of foreign currency. This inspired the Group to enter the tiles manufacturing business in 2001. By producing tiles locally, we saw an opportunity to not just to reduce import dependency but also value add and create well-paying jobs,” Ruslan Nasir, Deputy Managing Director of Mir Ceramic Limited (MCL), told the Ceramic Bangladesh magazine. He said, once upon a time, there were only a handful of companies producing tiles in Bangladesh. Most tiles produced locally were unable to meet international standards. Mir Group established MCL with a clear objective: to make the strongest and longest lasting tiles in Bangladesh. Since its inception, Mir Ceramic has utilised Italian manufacturing equipment. MCL secures only the highest quality raw materials.

or local and foreign investors “Once the use of ceramic products in Bangladesh was comparatively low. This was due to low purchasing power of people and high cost of ceramics products at the time. Earlier, the country was heavily dependent on imports spending huge amounts of foreign currency. This inspired the Group to enter the tiles manufacturing business in 2001. By producing tiles locally, we saw an opportunity to not just to reduce import dependency but also value add and create well-paying jobs,” Ruslan Nasir, Deputy Managing Director of Mir Ceramic Limited (MCL), told the Ceramic Bangladesh magazine. He said, once upon a time, there were only a handful of companies producing tiles in Bangladesh. Most tiles produced locally were unable to meet international standards. Mir Group established MCL with a clear objective: to make the strongest and longest lasting tiles in Bangladesh. Since its inception, Mir Ceramic has utilised Italian manufacturing equipment. MCL secures only the highest quality raw materials.

Ruslan Nasir said, “Mir has played a pioneering role in the manufacture of quality tiles by being the first local company to utilise European machinery. From day one, we were very serious about the quality of our products. This helped establish Mir as one of the largest and most trusted tiles manufacturers in Bangladesh. Till date, Mir Ceramic is the only ceramics company to be awarded the prestigious President’s Industrial Development Award.” “However, the company faced many challenges in the early days. One of the greatest challenges was the lack of skilled manpower at that time. Mir invested heavily in skill development, through a combination of hiring workers with international experience and hiring foreign trainers to develop local talent. Skilled manpower development, combined with world-class machinery and raw materials, helped Mir Ceramic bring tiles of international quality to the Bangladesh market.”

In the last 10 years, the ceramics sector in Bangladesh has experienced phenomenal growth. Today, locally made high-quality ceramic products are more readily available in the country. Recent studies reveal that local capacity is now capable of fully meeting the demand and accounts for over 80% of local consumption. Local manufacturers are benefiting from economies of scale thus driving down prices. This has made locally made ceramics products affordable to a larger segment of the population. As a result, the ceramic sector in Bangladesh has grown 200% in the last decade, creating 60,000 jobs directly in the process and 5,00,000 indirectly.

Founder of Mir Ceramic Ltd. and Managing Director, Mir Nasir Hossain is a leading business figure of Bangladesh. He has served as President of the Federation of Bangladesh Chambers of Commerce and Industries (FBCCI), the apex trade organisation. He established Mir Ceramic with a clear objective of producing the strongest and longest lasting tiles in Bangladesh. As Managing Director of Mir Telecom Ltd., Mir Nasir Hossain has received the National Export Trophy (Gold) from the Prime Minister of Bangladesh on multiple occasions.

However, the industry has faced significant challenges in recent times which could threaten that growth in the future. The biggest challenge is the ongoing disruption to the supply of natural gas. Manifold regulations are also causing hurdles for both local and foreign investors in Bangladesh. Other challenges include the long processing times at Chittagong Port when releasing our imported raw materials. We also urge the government to consider removal of the supplementary duty on ceramic products. Ceramics products such as tiles and sanitary ware are now commonly used all over the country and can no longer be considered a luxury item. Furthermore, we play an important role in improving sanitary conditions for the people of this country. As such, we believe it is time to remove the supplementary duty on these products.

If the government can resolve these problems, this sector can continue its momentum and grow, not just locally but also claim a larger share of the global market. Tableware items made in Bangladesh are already very popular in the international market. With the right policy support, tiles and sanitary ware exports can also grow, especially in neighboring countries such as India and Nepal, as well as the Middle East and Europe.

Speaking of the future market, Ruslan Nasir said, “Mir is no longer content with simply being a leader in quality. We aim to be leaders in design and innovation. With increasing access to the internet and more international travel, our consumers are more in tune with international trends than ever before. The tastes and preferences of our customers are constantly changing.

To continue to meet their evolving needs, MCL has invested heavily in the latest manufacturing technology and in skill-development amongst their workforce. Whether its new products, designs, or sizes, Mir always aims to be the first to embrace it.” He said “We plan to continue investing towards capacity building, not just in tiles but also in complimentary products. This crucial to only meet the growing demand in the country but also to remain competitive in an ever more competitive landscape.”

Written by Rafikul Islam