COVER STORY

A Litmus Test for Bangladesh Economy

It began with a verdict. Not a speech, not a scandal—just a quiet ruling from Bangladesh’s judiciary. On June 5, 2024, the High Court reinstated a quota system for government jobs, reserving 56 percent of positions for specific groups, including descendants of freedom fighters. For many students, it felt like a door slamming shut. Within days, campuses across the country stirred with frustration. The movement that followed—Students Against Discrimination—was born not in fury, but in resolve. Their rallies were orderly, their chants measured. But beneath the surface, tension simmered. By early July, that tension boiled over. The protests evolved into the “Bangla Blockade,” a sweeping shutdown of roads and highways that paralysed the nation’s arteries. Buses vanished. Containers stacked up at ports. Supply trucks idled outside factories. Dhaka’s markets emptied as perishables spoiled in the heat. Exporters missed deadlines. Small traders watched their earnings evaporate. What began as a student movement had metastasized into an economic crisis. DEFINING MOMENTS June 5 | 2024 High Court reinstates quotas June 7-15 | 2024 Students begin peaceful rally, social media activism July 01 | 2024 Nationwide Bangla Blockade begins July 16 | 2024 Violent crackdown, leaving dozens killed Late July | 2024 FDI approvals drop 40%; export delays, gas shortages August 5 | 2024 Interim Government formed Sep–Dec | 2024 Interest hits 10%; ADP spending 49-year low Jan–Mar | 2025 Remittances peak; inflation eases; current account surplus Apr–Jul | 2025 Recovery phase: DSEX up 12.5%; exports rebound; MFS grows 64% August 5 | 2025 One-Year Anniversary A Nation on Edge On July 16 of 2024, the calm shattered. Security forces moved in with batons, tear gas, and live ammunition. The clashes were brutal. Ambulances raced through smoke-filled streets. Students lay bloodied on stretchers. Families camped outside police stations, desperate for news. Independent monitors reported hundreds injured and dozens dead. The government disputed the numbers. But the images—broadcast across television screens and social media—left little room for doubt. The shockwaves were immediate. Investor confidence collapsed. The Dhaka Stock Exchange saw its sharpest single-day drop in five years. Foreign direct investment approvals fell nearly 40 percent in the second half of 2024, according to the Dhaka Chamber of Commerce and Industry. The city, once buzzing with commerce, fell into a hush. Three weeks later on August 5, an interim government was announced, led by Nobel laureate Muhammad Yunus along with a panel of technocrats and civil society leaders. Their mandate: restore stability, rebuild trust, and prevent further economic unraveling. The Economic Aftershocks The July Uprising, as it came to be known, left no sector untouched. While the garment and ceramic sectors bore the immediate brunt, the ripple effects extended far wider. The banking system, already strained by years of financial irregularities, teetered on collapse. A post-uprising asset quality review revealed widespread non-performing loans and misappropriated funds, prompting the interim government to initiate recovery drives and liquidity injections. The Bangladesh Bank raised the policy rate to 10 percent to tame inflation and stabilise the exchange rate. Net foreign direct investment (FDI) dropped to a five-year low in 2024, as global investors cited political instability and opaque regulatory frameworks. The World Bank flagged Bangladesh’s deteriorating investment climate, while local chambers warned that the budget lacked a clear roadmap for restoring investor confidence. The energy sector faced dual shocks: gas shortages crippled industrial output, while privatisation efforts triggered an 18 percent hike in urban electricity tariffs, sparking fresh protests. The mental health toll was staggering. A Bangladesh Medical University seminar revealed that 82.5% of injured protesters suffered from depression, and 64% showed signs of post-traumatic stress disorder, underscoring the long-term human cost of the crisis. In the ceramic industry, 70 factories struggled to stay afloat. The Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA) reported that gas pressure—critical for kiln operations—dropped to as low as 2 PSI in some zones, far below the required 15. Production stalled. Costs soared. Their demands were precise: uninterrupted gas supply, priority allocation, compressor permissions, a five-year tariff freeze, and duty-free solar imports. None were met. The garment sector fared no better. The Bangladesh Garment Manufacturers and Exporters Association (BGMEA) confirmed shipment delays averaging two weeks during the unrest. Export Promotion Bureau (EPB) data showed a 7.8% decline in garment exports in Q3 of 2024. Buyers in Europe and North America have shifted orders to Vietnam and India. Smaller exporters faced penalties and lost contracts, according to the Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA). The Foreign Investors’ Chamber of Commerce and Industry (FICCI) called for stronger rule of law, faster customs clearance, and smoother approvals. The Bangladesh Chamber of Industries (BCI) highlighted the plight of agro-processors, many of whom faced wastage and layoffs. Their appeal: concessional loans and tax relief. Even real estate, long seen as a safe haven, stumbled. The Real Estate and Housing Association of Bangladesh (REHAB) reported a sharp drop in property transactions, citing high registration fees, interest rates, and uncertainty over the Detailed Area Plan (DAP) revisions. Across industries, the message converged: without urgent reform, Bangladesh’s hard-earned gains risked slipping away. The Numbers Behind the Crisis The numbers told a sobering story. By late 2024, exports faltered, imports shrank, and growth slowed to its weakest pace in years. The disruptions that began with student protests soon seeped into every corner of the economy, from factories to food markets. Inflation surged through the summer, eroding wages and squeezing households already under strain. Though the pace of price rises eased the following year, the scars remained. Construction sites went quiet, housing demand collapsed, and long-promised infrastructure projects were postponed. The slowdown was no longer abstract—it showed in half-finished bridges and shuttered shops. Private investment also lost its footing. Business registrations dwindled, banks groaned under bad loans, and confidence withered. Even as revenue collection improved, it could not

Read More

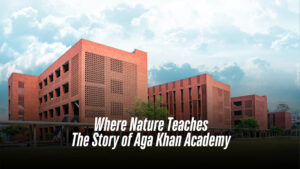

Where Nature Teaches: The Story of Aga Khan Academy

In Dhaka’s Bashundhara Residential Area, the Aga Khan Academy immediately catches your eye. Its warm brick walls, softened by greenery and a sparkling water channel, glow in the morning light. The building feels like a historical monument—orderly courtyards, intricate brickwork—yet the lively chatter of students reminds you this is a school—a place where learning blends seamlessly with nature’s rhythms. Bangladesh’s heritage that make it truly remarkable. Here, architecture becomes a canvas, interiors breathe with narrative, and every art installation stands as a tribute to the nation’s soul. Spanning in 17 acres, the award-winning Aga Khan Academy in Dhaka was developed through a collaboration between SHATOTTO Architecture for Green Living and Feilden Clegg Bradley Studios. The design draws inspiration from the region’s ancient Buddhist Mahaviharas, incorporating their architecture and philosophy into the campus. A clay model was used to visualise the design, helping stakeholders understand the campus’s spatial organisation before construction. Covering 74,150 square metres, this is Shatotto’s largest school project to date. The campus provides a green sanctuary within Dhaka’s urban environment. This academy represents a significant investment by the Aga Khan Development Network in Bangladesh’s future. As the fourth institution in a planned network of 18 Aga Khan Academies across Africa, South and Central Asia, and the Middle East, the Dhaka campus connects students to a wider academic and cultural community. Other campuses are located in Mombasa, Hyderabad, and Maputo, forming a global network focused on pluralism, leadership, and excellence. To support education from nursery to diploma level, Aga Khan Education Services required a permanent campus. This presented a challenge in a dense city like Dhaka. The project is designed to be scalable and sustainable, planned in seven construction phases. Since its first phase launched in September 2022, the academy has offered an integrated environment that connects nature with education, providing a calm setting within Bashundhara’s urban area. The Dhaka campus currently enrolls 750 students, with plans for expansion to 1,200. The masterplan includes residential facilities designed to accommodate students and staff from across Bangladesh and other countries. This lays the foundation for a diverse and inclusive learning environment upon full implementation. The vision for this project was led by Architect Rafiq Azam of Shatotto Architecture for Green Living, who incorporated Bangladesh’s heritage into the design. He conceptualized it as an “archaeological site, like our ancient monasteries.” Co-lead Architect Peter Clegg of Feilden Clegg Bradley Studios contributed global standards and technical precision. A central amphitheatre serves as a space for performances and gatherings. The adjacent Maidan, a large open playground, accommodates student activities, serving recreational and social functions. Brick buildings surround these shared areas on a planted base, offering unobstructed views of the Maidan from all directions. The Maidan functions as the campus’s central point, reflecting the spirit of ancient Buddhist Mahaviharas. These elements collectively support an environment where the physical space contributes to the educational process. “The school itself teaches,” says Rafiq Azam, lead architect of the Aga Khan Academy. “Students learn from books inside the classroom, but when they step outside, they begin to notice surroundings on their own — how water flows, how flowers bloom, how the sun moves across the sky, and how the breeze blows from a certain direction.” He adds, “This kind of learning happens naturally, guided by the environment rather than just by the teacher. The process encourages students to learn independently, beyond what is taught in the classroom.” Rafiq Azam emphasised the local context influencing the design, noting the significance of greenery, water, and rain in Bangladesh’s fertile landscape. This sensitivity is integrated into the campus layout, where natural elements are part of daily student life. The academy’s design heavily features brick, chosen for both its practical and aesthetic qualities, consistent with Bangladesh’s architectural history. Each brick is carefully positioned. According to Feilden Clegg Bradley Studios, brick was selected to revive local craftsmanship and to contrast with the render and concrete common in surrounding new buildings. The construction method involves deeply embedded mortar between brick pairs, a technique seen in historical sites, ensuring longevity and a timeless appearance. This strategic use of locally sourced brick, combined with Bangladeshi brick patterning, creates a cohesive campus. It establishes a hierarchy of spaces through its brickwork. Facade perforations allow daylight into interior corridors, using traditional techniques. Recessed windows, screens, and protruding brick columns provide shading for classrooms and create covered balconies and walkways. Classrooms are oriented to minimise solar gain in summer, with external walkways and adjacent buildings providing passive solar shading from the morning sun throughout the year. This ensures adequate daylight and outdoor views. Architects designed these spaces for passive heating and shading year-round to minimise energy consumption. This climate responsiveness was achieved through extensive sun pattern analysis and wind flow direction studies, optimising light and ventilation. The academy’s character reflects many original Buddhist universities in Bangladesh. It is defined by the massing and materiality of brick buildings located on a sculpted and planted landscape base surrounding the central Maidan. Alongside the main field, the complex includes smaller connected areas featuring concrete canopies for shelter, along with brick benches and planters. These peripheral spaces serve as transitions between the central Maidan and more intimate interior areas. Spaces are tailored for different age groups; for example, the senior courtyard offers shaded zones under planted trees for focused group activities. The assembly court is simple, with four ‘Dhaak trees,’ which inspired Dhaka’s name. The primary central courtyard accommodates larger gatherings and includes an amphitheatre built around a sand pit. This pit is designed to collect rainwater during heavy rainfall, holding up to 170 mm of water for approximately 10 to 30 minutes. The campus masterplan organises spaces into four zones—Intellectual, Moral, Physical, and Spiritual—supporting a holistic educational philosophy. Each block is designed for a specific function. The Academic Block, a central hub, contains administrative workstations, learning centers, group study areas, and a lecture hall, along with a terrace. Its white-walled classrooms vary in

Read More

14th ISSUE

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far.

Read More

A stunning display of architectural grandeur, welcoming students

We are all familiar with the Dhaka University and its grandeur. Even now, when major infrastructures shroud the beautiful campus, its thousands of students still enjoy a little retreat among greeneries in, for example, Muktamancha or Suhrawardi Udyan. The same can also be said for all public universities. It’s on one such campus where BUET alum Khandaker Ashifuzzaman Rajon, Principal Architect of Cubeinside Design Limited, studied architecture. Of course, Rajon’s idea of a campus vastly differs from that of private university students. Thus, when tasked with designing a campus for Southeast University (SEU) well within the hustle-bustle of Dhaka, Rajon had to tumble down all his cards and think of fresh ways to give the students of Southeast University some taste of his own campus-going experience. The project being the permanent campus came with the additional worry of how to design the structure that would inspire students to enrol just looking at the place years, even decades, after its novelty factor has worn off. But before we go further into Rajon’s and the Southeast University permanent campus story, allow us to tell you what it is about all private universities competing to move to their permanent campuses. Competition here is particularly good, as all private universities want a permanent campus that is the most student-friendly while being attractive. UGC, the University Grants Commission, recently stipulated that all private universities, without fail and exception, move to a permanent campus that facilitates students with open space, interactive classrooms, and all the amenities that university students abroad enjoy from a campus. So, that triggered the mass relocation of private universities to actual campuses in place of stuffy buildings. Rajon opened his story with the mandatory 50% open space policy in the rulebook for building a new permanent campus. “The idea of a cubic volume in the centre of the campus came from this rule. I wanted the rest of the structure to look over the open space as the centerpiece of the campus. As a by-product, a central courtyard would help dissipate light and aerate its surroundings, like the classrooms, for example. However, the Board wasn’t initially unanimous about the central open space idea, but it was up on completion that they saw my vision behind this design choice, and this later became everyone’s favorite part of the entire campus,” began the architect. But beyond the Board’s stamp of approval, the campus just had to be completed and made fully functional within a very limited window of time, set by the UGC. If you happen to be a current student of SEU or have even visited the place, you may have taken a moment’s pause and thought of how it was even possible to erect an edifice as such in such a constricted amount of time. This is where the seasoned, but young, architect’s ingenuity just begins. If my memory serves well, I remember seeing in the popular cartoon show “Popeye: The Sailor Man” Popeye stacking floors upon floors of a skyscraper with steel I-beams, all in one shift, of course with the help of his special formula spinach, but steel I-beams were the actual hero that allowed for construction at such mind-boggling speeds. I am not inferring that Rajon got his hands on Popeye’s spinach, but being the well-bred architect that he is, he knew that I-beams would be an ideal instrument in his race against time. He explained how: “All the brick and concrete facades of the entire complex give it the impression of an RCC (reinforced cement concrete) structure, but its basic skeleton is made of I-beams. This bought me time! I-beams, like Lego, just have to be joined together using nuts and bolts without trading modern looks for time or structural integrity, but we did trade off some extra money to be able to complete construction in time.” The mission he had in mind to let light dance around the entire complex with the help of a central open space was a massive success. As the structure was shaping up rather quickly, it was instantly visible that the same campus took on different faces because of the changing sunlight that entered at different angles at different hours of the day. As a creator, the play of light and shadow had Rajon all emotional when he laid eyes upon the outcome. “The place would change its look at the change of each season too,” he said. “A few of my acquaintances who study at SEU find the campus quite photogenic. As climates change, they post photos and reels of different parts of the campus on their social media, and from there, I get to observe, from an onlooker’s perspective, how the most important beneficiaries of the campus—who are the students—are lovingly accepting it and are also low-key boasting it on their socials.” All this is to say that a structure made exclusively out of complex mathematics and engineering can also evoke emotions when made with the human angle in the mix. Ever since the permanent campus opened its doors to students in early 2023, the entire place teems with students in any direction imaginable. Not only is that the proper utilisation of space, but it also points towards the inevitable fact that students love their new campus. Everyone is doing what a student does: going in and out of class, singing, laughing, teasing, playing with classmates between classes, and most importantly, enjoying their newfound freedom in such a capacious facility that can house over 12,000 students at once! The former campus building is in the backyard of the new campus. It will be demolished soon and replaced by a new building to house the School of Engineering. It is to be designed by Cubeinside Design Limited as well. “But looking at the design of the new building and the one we just completed, no one will be able to say that the same architecture firm was behind the drawing board of the second one; it’s that different from the

Read More

A palace on the bank of Buriganga

An integral part of Dhaka’s image in terms of historical architecture that still remains and has been renovated and preserved is the Ahsan Manzil. And like many of common folks who grew up in Dhaka, they have always wondered, at least once in their lives, the reasons behind why this iconic landmark is painted pink. Perhaps unsurprisingly, Ahsan Manzil’s history is even more colourful. This iconic building was built on a property that has a rich history dating back to the Mughal era at the southern part of Dhaka. During the Mughal Empire, Sheikh Enayet Ullah, Zamindar of the Jalalpur Porgona (Faridpur-Barishal), who was the original owner of the land, built a palace called Rong Mahal (which loosely translates as ‘Colourful Palace’) in 1720 for his amusement, a typical practice amongst wealthy elites at the time. He also had a garden house and a cemetery on this site. After he passed away, his son Sheikh Moti Ullah sold the property to the French traders in Bengal at the time. The new owners soon established a trading house next to the palace. Later, after being defeated in the Palashy War by the British East India Company in 1757, they had to leave their possessions behind. After changing hands a number of times, the property was purchased by Khwaja Alimullah of Begambazar in 1830, who was a prominent merchant and an important figure of Dhaka’s Muslim community at the time. Alimullah renovated the property, turning the trading house into a residence. He also built a mosque and some other important structures in this area. After his death in 1854, his son Khwaja Abdul Ghani inherited the property and named it Ahsan Manzil after his son Khwaja Ahsanullah. He continued renovations; the old building was renamed Ondor Mohol (ladies quarters) and the new building was called Rangmahal (pleasure palace) and was later renamed Ahsan Manzil. Khwaja Abdul Ghani was one of the most influential Nawabs (Zamindar) of Dhaka. Known for his generosity and patronage of arts and culture, he expanded his estate by acquiring more lands around Ahsan Manzil and also played an important role in improving the infrastructure, education, healthcare, trade, and social welfare of Dhaka. In 1859, he built a new building on Ahsan Manzil’s property that resembled European architecture because of its domes and pillars. The Nawab named it Rangmahal and painted it with different colours every year according to his mood. On 7 April 1888, Ahsan Manzil suffered severe damage from a tornado that impacted most of its buildings, except for Rangmahal and it was temporarily abandoned. Khwaja Abdul Ghani then decided to rebuild Ahsan Manzil with more vigour and decorations than previous ones. He hired Martin & Co., a British construction and engineering f irm, who designed Ahsan Manzil with an Indo-Saracenic style, blended with Islamic and European elements. In 1872, the reconstruction work continued under Khwaja Abdul Ghani’s supervision, what was previously the French trading house was rebuilt as a two-storey building similar to the Rangmahal. A wooden bridge connected the first floors of the two buildings. After he died in 1896 at the age of 87 years, his son Khwaja Ahsanullah continued his father’s legacy by taking care of the palace. He added new features like electric lights, gas lamps, and water pumps as part of modernization. The palace was repaired again following the 1897 Assam earthquake. The Nawab family played crucial roles in the modernisation of the Dhaka city, particularly in the development of educational systems, healthcare, and urban infrastructure, including the f iltered water supply system that served the city population. They occupied important positions as Commissioner of Dhaka Municipality. Today, within the hyper-congested and cacophonous urban growth of Old Dhaka, it is difficult to imagine how this majestic edifice once dominated the riverfront skyline of Dhaka. The landmark is a unique fusion of architectural styles, reflecting the rich cultural influences that shaped Bengal it over the centuries. The main palace building showcases a harmonious blend of Mughal and European architectural styles. The Mughal influence is evident in the structure’s domes, arches, and intricate decorative motifs. The ornate design of the palace’s entrance and interior chambers reflects the opulence that was characteristic of the Mughal era. European influences, on the other hand, are seen in the high ceilings, broad staircases, and expansive verandas. The palace’s central ballroom, adorned with crystal chandeliers and European-style furniture and tableware, exudes an air of sophistication that was imported from Europe during the late 19th century. The building faces the Buriganga River and Buckland Dam. On the riverside is a stairway leading up to the 1st floor. A fountain previously sat at the foot of the stairs but was not rebuilt. Along the north and south sides of the building are verandas with open terraces. Ahsan Manzil is ostentatiously European in its architectural expression, even though the building’s recessed verandahs may recall the Mughal treatment of buildings in a tropical climate. Its triple-arched portal, Greco-Roman column capitals, pilasters, and arched windows—all suggest that it is mostly a European-style building, meshed with some decorative Indian motifs. The palace’s soaring dome appears to be more about impressing the viewer on the exterior, rather than within the interior. The dome is at the centre of the palace and is complex in its design. The room at its base is square with brickwork placed around the corners to make it circular. Squinches were added to the roof corners to give the room an octagonal shape and slant gradually to give the dome the appearance of a lotus bud. The dome’s peak is 27.13 metres (89.0 ft) tall. The palace is divided into the eastern side, the Rangmahal, and the western side, the Andarmahal. The Rangmahal features the dome, a drawing room, a card room, a library, a state room, and two guest rooms. The Andarmahal has a ballroom, a storeroom, an assembly room, a chest room, a dining hall, a music room, and a few residential rooms. Both the drawing room and

Read More

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far. Its rich history, architectural significance, and constant activity make it an iconic landmark. With a unique design and historical roots, Kamalapur Railway Station weaves together the fabric of Bangladesh’s rail network. The station’s significance has increased following the opening of the Padma Bridge. Kamalapur Railway Station (KRS), steeped in history, stands as Dhaka’s historic gateway. Its iron-clad colonial-era architecture evokes memories of a bygone era, a bridge between past and present. But Kamalapur is more than just a transit point; it embodies the spirit of a nation on the move—a pulsating heartbeat that reverberates across Bangladesh. Kamalapur Railway Station stands as a vital link in Bangladesh’s transportation network, connecting people, cultures, and commerce. As trains arrive and depart, the passengers weave intricate stories etched into the very walls of this magnificent station. Here, hope mingles with anticipation, dreams find their rhythm, and reunions unfold. The station’s bustling platforms witness resilience—the quiet strength of travellers forging ahead despite life’s twists and turns. And within its echoing halls, new beginnings take root, fueled by the promise of distant horizons. Kamalapur Railway Station, standing tall against the passage of time, is a living testament to Bangladesh’s architectural ingenuity. It’s not merely a physical structure; it’s a gateway to aspirations, connections, and the beating heart of a nation. As passengers step onto its platforms, they become part of a grand narrative—a journey that transcends mere destinations and becomes an enduring legacy of rail travel in Bangladesh. Architectural Marvel Kamalapur Railway Station stands as a captivating blend of modernity and tradition. More than a mere transportation hub, it represents an architectural marvel that seamlessly connects the past with the present. Designed by the renowned American architects Daniel Dunham and Robert Boughey (Bob Buie) of Louis Berger and Consulting Engineers Ltd. in the 1960s, Kamalapur Railway Station serves as a symbolic gateway to Dhaka. Daniel Dunham, a young architect fresh from completing his studies at Harvard’s Graduate School of Design (GSD), took charge of Berger’s fledgling Dhaka office. His task was to tackle an extensive backlog of new projects. The station’s architecture draws inspiration from both modernist principles and traditional neo-Islamic influences, as well as Bengali styles. It stands as a testament to Dhaka’s modern architectural spirit. Architect Daniel Dunham skillfully blended modernist elements with traditional Bangladeshi architecture. The station’s most striking feature is its parabolic shell roof—a true engineering masterpiece. Stretching over the platforms, this roof provides shelter to passengers. The lattice-like concrete structure fosters openness and allows natural light to filter through, creating a welcoming ambiance. Kamalapur Railway Station officially opened on May 1, 1968, during President Ayub Khan’s tenure. Its construction cost at the time was Taka 5 crores 30 lakh. When the value of one vori of gold stood at only 100 takas, A year after its inauguration, the Provincial Office of the Railway Postal Service found its new home within this remarkable station building. Design Features The station building is well-suited for tropical climates, providing protection from rainwater like an umbrella. It incorporates various functional spaces, including ticket booths, administrative offices, passenger lounges, waiting areas, and restrooms, all under an integrated canopy-based roof. The structure comprises 36 square domes supported by a total of 49 columns. Above these columns stands a roof featuring 36 slender concrete umbrella-type domes. Each column extends 59 feet high, branching out to support the roof. The open-air design capitalises on Dhaka’s cross breezes while safeguarding interior spaces from monsoon rains. The Kamlapur Railway Station’s thin concrete shell dome-umbrella design, completed by the consultants, has become a local icon, cherished by prominent architects as a cultural heritage piece. The parasol roof continues to define the station’s unique skyline. Architect Dunham immersed himself in Bangladeshi culture, learning Bengali and adapting to local craftsmanship and construction practices. Instead of designing an enclosed monolithic structure with mechanical heating and cooling systems, Dunham leveraged Dhaka’s tropical climate. His innovative roof system provides shade over the station’s offices and facilities, supported by a versatile field of columns. The construction technique involves thin concrete shells, which Dunham explored during his thesis at the GSD. After Dunham’s departure, architect Robert Boughey took over the post, designing tessellating concrete shells for the roof, reminiscent of pointed arches seen in Islamic architecture. These shells were cast on-site using reusable materials. Kamalapur Railway Station, with its remarkable parabolic shell roof, stands as an engineering marvel. This expansive structure spans the platforms, providing shelter to passengers. The station’s circular layout, boasting a diameter of 186 metres, centres around a soaring dome that reaches a height of 26 meters. Eight radial wings extend from the central hub, housing platforms, and tracks. The station’s architecture seamlessly blends modernist elements with traditional Bangladeshi motifs, reflecting the nation’s spirit. The concrete lattice structure allows natural light to filter through, creating an airy and open ambiance. High ceilings and spacious interiors enhance the feeling of grandeur. Kamalapur’s design prioritises functionality while maintaining aesthetic appeal. Geometric patterns, arches, and intricate details evoke the essence of Bengali culture. As a testament to Bangladesh’s identity and heritage, Kamalapur Railway Station stands proudly. The station is an engineering marvel that spans the platforms, providing shelter to passengers. Additionally, in other parts of the country, the Sylhet Railway Station in the north-eastern region and the Chilahati International Rail Station in the north-western part also feature a similar umbrella-like structure. These stations use national flower-shaped “shapla” shells supported by a forest of columns to cover their facilities. Historical Context Bangladesh Railway has been operating in the British period since 1862 in the eastern and western parts of the country, divided by the great river

Read More

Kamalapur Railway Station: A Gateway to Journeys in Bangladesh

Kamalapur Railway Station, officially known as Dhaka Central Railway Station, stands as a bustling gateway to the vibrant capital city of Dhaka. Nestled in the heart of the city, this vital transportation hub connects travellers to all major cities in Bangladesh. As the largest and busiest railway station in the country, Kamalapur serves as a crucial link, facilitating journeys both near and far.

Read More

Dream Train in the City of Oysters

Cox’s Bazar Rail Station has been built as a modern marvel for travelers. The new ‘green field’ of railway alignment has connected Cox’s Bazar, the top tourist destination and a rapidly developing region in Bangladesh. Finally, the long-term dream of tourists has been fulfilled. On November 11, 2023, Prime Minister Sheikh Hasina inaugurated the 102-kilometre dual gauge single railway line between Cox’s Bazar and Dohazari in Chattogram and the newly built Cox’s Bazar iconic rail station in the shape of oyster shell. The architect of the station, Mohammad Foyez Ullah, principal architect of Volume Zero Limited, took inspiration from the shape of an oyster for its exterior, which symbolises the beach. It is a station with marine atmosphere at first sight. With this, not only has the country’s leading tourist destination become more easily accessible, the entire southeast region is also poised for boosting trade and connectivity. The rail link project, the latest among several such communication-related projects, is part of an elaborate development scheme focused on Cox’s Bazar. Enhanced connectivity will be crucial for transportation of goods to and from Teknaf land port, as well as the growth of local industries including fish, salt, rubber raw materials, forest and agriculture products and dried fruits, according to local business experts. There are nine railway stations on this route, which means the surrounding areas will also see economic transformation. After Cox’s Bazar to Chattogram the stations are followed by Ramu, Islamabad, Dulahajara, Chakaria, Harbang, Lohagara, Satkania and Dohajari. The rail line will be extended to the Myanmar border, and to the planned deep-sea port on Matarbari Island. The extended part will have three stations – Ukhia, Teknaf and Ghumdhum (Bandarban). Cox’s Bazar Station to enhance tourists’ experience Nestled on a 29-acre expanse in Chanderpara, under the Jhilongjha union in Cox’s Bazar Sadar upazila, stands the paradise sighting station, located three km away from the sandy beach, built at a cost of Tk 215 crore. The six-storied building, covering 187,000 square feet area, captivates visitors with its unique exterior. The canopy serves a dual purpose — not only enhancing the station’s aesthetic appeal but also effectively cooling the building, ensuring proper air circulation, and welcoming ample natural light, according to the project engineers. Adding to the visual allure, a variety of coloured lights grace the front of the building, providing an artistic perspective to the station’s entrance. This station is Asia’s first 100 per cent tourist-friendly central air-conditioned multi-storied station. It has all kinds of facilities for tourists. Arrangements have also been made so that tourists can visit Cox’s Bazar in a day and return the same day without hotel accommodation. This railway is perfect Cox’s Bazar as an international tourist hub. It will be helpful to bring foreign tourists. Not only in the winter, tourists will be encouraged to visit Cox’s Bazar throughout the season including monsoon. In the construction of this iconic station, facilities of various modern stations of the world including China, Belgium, England, and Italy have been taken into consideration. A total of 250 engineers and more than 600 people, including 110 foreigners, were working in the entire project. After four years of hard work, the uniquely beautiful railway station building is visible today. On the ground floor, ticket counters, arrival and VIP lounges, ATM booths, Bank and forex service, pharmacy, post office, railway service office, baby care centre, information booth, and luggage lockers. The first floor offers a departure lounge, waiting lounges, display centres, locker room, prayer space, shops, and a cafe. Levels 2 to 5 house a shopping mall and food court, bookshop, five-star overnight stay option with dining, office spaces, restaurants, a multipurpose hall and hotel with recreational space for passengers. The hotel has 39 rooms. The fourth floor is intended to be leased for offices and conferences. Top floor reserved for future use. Travelers arriving at Cox’s Bazar by overnight train can conveniently store their belongings in lockers and explore the beach and other tourist spots during the day before catching a night train back to Chattogram or Dhaka. Tourists can leave their luggage in station lockers while they enjoy their time sightseeing at the beaches and tourist sites. Around 500 tourists will be able to keep their luggage in the station lockers at a time. As a result, tourists would be able to leave Cox’s Bazar without staying at night in hotel. However, they have to pay locker rent for this. The station is equipped with ample amenities, including escalators, lifts, parking area and refresh rooms for men, women, and those with physical disabilities. Accessing any of the three platforms is made easy with a footover bridge connected to escalators, staircases, and a ramp bridge facilitating movement between platforms. The rail station also features separate facilities for women, children, the elderly people. The Cox’s Bazar station has the capacity to transport around 50,000 people each day, as well as facilitate the operation of wagons for transporting fish, dried fish, salt and other items. Work of the project is being completed in two parts with China Railway Engineering Cooperation (CREC) and Toma Construction carrying out the first part from Dohajari to Chakaria and China Civil Engineering Construction Corporation (CCECC) and Max Infrastructure Limited are doing another part from Chakaria to Cox’s Bazar. Additional Deputy Inspector General of Tourist Police Cox’s Bazar region Apel Mahmud said the arrival of tourists in Cox’s Bazar will increase, thanks to the train service. All kinds of preparations have been made for the service and safety of tourists, he added. Passengers say the journey is enjoyable. A crooked rail line has been built through the green field and forest. Sometimes the hills touch, sometimes the eyes will be drawn to the unique beauty of the green village of Bangladesh. A hundred kilometers of railways has completed to see such a scene. Every station is equipped with relay batteries, generator rooms, sewage and waste management facilities, and energy-saving features such as solar panels. Both meter and broad gauge rail

Read More

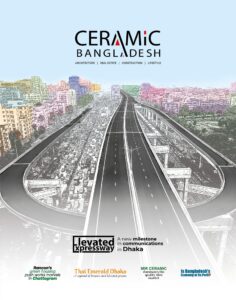

Elevated Expressway A new milestone in communications in Dhaka

The First Dhaka Elevated Expressway (FDEE) is called a ‘new milestone’ in communications and the project is being implemented under Public-Private Partnership (PPP) arrangement to alleviate traffic congestion in and around the capital. It has already been visible after inauguration of a portion of total of 46.73-kilometre-length with ramps, including a main elevated section spanning 19.73 km in the city. Prime Minister Sheikh Hasina inaugurated the 11.5 km part of it between Hazrat Shahjalal International Airport and Farmgate section, on September 2 with the key objective to shorten the lead time for exports and imports activities. Now people can travel the Airport-Farmgate site in 10 minutes thanks to the FDEE inauguration in the densely populated city. It often takes two hours to travel the 11.5 km due to severe traffic congestion. According to the First Dhaka Elevated Expressway Company Ltd, the total of 46.73-km-long elevated expressway is covering Airport, Kawla, Kuril, Banani, Mohakhali, Tejgaon, Magbazar, Kamalapur, Sayedabad, Jatrabari to Kutubkhali on the Dhaka-Chattogram highway. The entire expressway is expected to be opened for vehicles from Tejgaon to KutubKhali in June 2024. The FDEE project involves construction of a four-lane main carriageway and one elevated link road, comprising: four-lane dual main carriageway of a total length of 19.73 kilometers. It has a four-lane dual link-road carriageway of a total length of 3.1 kilometers. 32 on-off ramps including 16 on-ramps and 16 off-ramps (one-lane carriageway of 5.5 meter width) of a total length of 23.9 kilometers with 8 toll plazas and 43 toll collection booths. Besides the main four-lane dual carriageway and two suspended termini at its ends, it has five interchanges, two elevated links. The approximate total length of the main carriageway Expressway is about 46.73 km including 19.73 km main flyover and 31 km ramps and elevated links. Dhaka-Ashulia, Dhaka-Narayanganj and Dhaka-Chittagong expressways will also be connected with this elevated expressway in future. The project is one of the largest infrastructure projects taken up by the incumbent government spending a total of Tk 13,858 crore to ease traffic congestion. Of them, the cost of Airport-Farmgate section was Tk 8,940 crore. However, the FDEE project is being implemented under the PPP process between the government of Bangladesh, represented by the Bangladesh Bridge Authority (BBA), and the Italian-Thai Development Company Limited (ITD Group), represented by the First Dhaka Elevated Expressway (FDEE) Co. Ltd. According to the authority, around 80,000 vehicles can run on the FDEE a day. Chinese firm China Shandong International Economic and Technical Corporation, one of the three private partners of the PPP project, will operate the control centre. The FDEE is offlimits to three-wheelers and motorcycles. Other vehicles run on the structure at a maximum speed of 60km per hour in expressway and 40km per hour in ramps at the beginning. BRTC bus services commenced on the Expressway. The non-stop service, which began initially, runs with eight double-decker buses from Farmgate to the Airport. Road Transport and Highways authority said cars, SUVs, microbuses with fewer than 16 seats, and trucks with a capacity of less than three tonnes will pay Tk 80 for using the expressway. Trucks with six wheels will pay Tk 320, those with more than six wheels Tk 400, and buses with 16 or more seats Tk 160. Payment is being processed through e-ticketing. Local construction industries are thriving At least 10 local companies are making and supplying materials, such as cement, steel, stone and paint, for constructing the country’s first elevated expressway. Local products in place of imported alternatives are also being used in this mega project. This is not only saving foreign currency but also building the capacity of the local companies. A major portion of the Tk 8,940 crore project is being constructed using local materials. Of the 10 local contributors, six are cement companies while two are steel makers and the others make paint and PVC products. The cement makers are: Shah Cement, Crown Cement, Bashundhara Industrial Complex, Heidelberg Cement, Seven Rings Cement and Premier Cement. The BSRM and GPH Ispat are providing steel for the project while two concerns of RFL Group — RFL Pipe and Fittings, and Rainbow Paints — are supplying necessary pipes and road marking materials. RN Paul, managing director of RFL Group, said they are providing waste and rainwater pipes and fittings for the drainage system of the elevated expressway as well as road marking materials. Mr Paul explained that if local companies do not provide the required construction materials, then they would have to be imported at the cost of huge sums of foreign currency. “So, local companies benefited and also the process helped save foreign currency through such cooperation,” he said. Till September 2023, a total of 66,000 tonnes of steel has been used in the elevated expressway project, with BSRM contributing a majority 52,000 tonnes (80%). Tapan Sengupta, deputy managing director of BSRM, acknowledged that involvement in this type of large project helps local construction material companies grow their capacity and achieve global standards. Sheikh Masadul Alam Masud, founder chairman of the Bangladesh Steel Manufacturers Association, said the local steelmaking capacity has nearly doubled to about 9 million tonnes over the past decade. Local cement manufacturers have increased their production capacity to 6 million tonnes per annum while it was 2 million tonnes annually just 10 years ago. Back to history In January 2011, the certificate authority (CA) was signed between Bangladesh government, represented by Bridges Division, the Ministry of Road Transport and Bridges, acted through Bangladesh Bridge Authority (together the “grantor”), and First Dhaka Elevated Expressway (FDEE) company limited (the “concessionaire”). The ITD, the largest construction company in Thailand, established first Dhaka Elevated Expressway Company Limited (“FDEE”) as a 100%-owned special purpose vehicle, registered in Bangladesh, to accede ITD as the concessionaire in the concession agreement for implementation of the project. The BBA signed deal with Italian-Thai Development Public Company to build the FDEE at a cost of Tk 8,703 crore in January 2011. The agreement was revised and inked again in

Read More

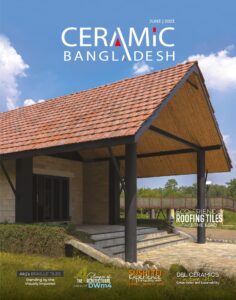

ECO-FRIENDLY Roofing Tiles TAKE THE LEAD Industry challenges need to be addressed, say entrepreneurs

Time is NOW for eco-friendly clay-made roofing tiles and now is TIME for tile makers. They are the Bangladeshi makers of clay tiles who have gone global as their tiles have opened up the door of a huge export possibility, especially to Europe. The making of clay tiles is simple but it needs amazing artistry as well as artisanal skills. Fluffy mud is made by mixing soil and water. It then dries in the sun and is burned only to turn into clay gold. The artistic tiles with Bengal clay have revolutionised the style. However, clay artisans were once about to lose their hopes and dreams with their centuries of tradition. They then have turned the corner and things are looking up with the coming of the modern machine-driven industry. The clay artisans have turned around to weave a new web of hopes and dreams. Famed for its ‘Tiles Empire’ over the years, Satkhira has eco-friendly roofing tiles to its credit. Kolaroa Bazar in Kolaroa upazila, some 18 kilometres of district headquarters, is one of the prosperous trading points in Satkhira. Murarikathi village is located just 1.0 km away from the upazila headquarters along the border of the district. The artisans of Murarikati-Sripatipur have built an empire of various sorts of roofing tiles. The village, also called Kumarpara, has now got the moniker ‘Italy Town’ plausibly for exporting a massive volume of tiles to the European country. Tile factories used to produce 700-800 containers a year just a few years back. Some 300-400 container tiles were exported to Italy through Mongla seaport. The price of the product per container is average US$ 15000 Eco-friendly tiles Eco-friendly tiles There is a huge local market for roofing tiles if these hand-made tiles are given a more modern touch and the initiative is taken to use them as an artisanal tile in buildings and structures. During the British raj, cottages, offices or residences of the gentlemen used to have tiles at the peak that are still visible in the ancient architecture of Britain. Although a large number of potters have left Bangladesh, some in Kolaroa have kept the traditional tile industry alive in the frontier district. Until the mid-1960s, there were hardly any houses in the country that did not have a tile-made house or two. As it came cheap, roofing tiles became popular after rice and wheat straw-built structures. The structures were felt cool and comfortable during the summer. How Palparaenters European market The traditional tiles industry almost sank into atrophy when the potters associated with tile production left the country in the mid-60s. Satish Chandra Pal, a native of Palpara in Kolaroa, started crafting house canopy tiles in about 1952. From there, potters spread across the country. As Mr Satish Chandra died after independence, the pottery business simply collapsed. Due to their deep-rooted poverty, many artisans left their ancestral profession. With the passage of time, the potters have changed. They are now making tiles using clay. In 2003, local potters created a revolution by pouring clay into a wooden frame and drying it in the sun, making Bengali tiles in line with Italian design. Since then, Bengali tiles are being exported to Italy How are the legacy-bearers? Among those artisans is Gostho Chandra Paul, the president of Kolaroa Upazila Tali Malik Samity [Tiles Owners Association] and also proprietor of Kolaroa Clay Tiles. But he now struggles to survive as his long-cherished art is on the verge of extinction for a number of reasons. The 60-year-old Paul, who has a three-member family, is producing 1,000 units of tiles at his factory per diem. Each unit is currently being sold at Tk 8.0. He earns Tk 1.6-1.7 million per annum. Getting disgruntled and disappointed over the waning business situation, most owners and workers associated with this industry have already lost their jobs. Mr Paul observed that modernity has affected almost all sectors of the country. However, the tiles industry is yet to get the touch of modernity. Production costs have increased manifold, but the price of tiles has not increased. Mr Paul’s forefathers launched crafting eco-friendly roofing tiles in 1947. However, it all started for Mr Paul in 1986 when he set himself up in business with Tk 3,000 only. Ten workers were employed at his factory when he started crafting eco-friendly roofing tiles traditionally. His uncle told him to be self-reliant and build his own future through the long traditional business, which he acquired lineally. But at least 40 tile factories got shut down in the past six years due to their persistent business losses. Now, the number of factories there is about 12. Almost 6,000 workers become unemployed and only 600 are absorbed elsewhere. For generations, the Pal community in the locality has been contributing a lot to this thriving sector. Mr Paul is also committed to continuing their forefathers’ business at any. In 2003, this clay tile was first exported to Italy. Businessman Ruhul Amin exported the eco-friendly tiles there. Arno Export Import, Shuvo Trade Limited, FH Khan Limited, Maa Cottos Inc., Nikita International, Koto Innovator, JK International, Polo Epo Organic Tiles and D Chandra Paul have followed Mr Amin’s footsteps. They are exporting tiles to Italy, Dubai, France, the UK, Australia, Germany and the Netherlands. Mr Chandra Paul, proprietor of Kolaroa Clay Tiles, said Mr Amin continued to look for suitable soil in different parts of the country for exporting tiles to Italy. Finally, Mr Amin found his desired soil in Murarikati area. He is the pioneer in exportable tile business. As the number of roofing tile factories increased in Kolaroa until 2019, the stock remained high at the time. Every year, 300-400 containers of tiles went to Italy. Such tiles are manufactured and sold for 6-7 months in a year. Usually, tile-making season starts from October and continues until the May-June period. Tiles cannot be crafted during the rainy season. Foreigners are using the tiles for floors and walls of their houses because of its eco-friendly nature.

Read More

MODEL MOSQUES A Unique Gift to Society Message of peace, culture of harmony to be promoted in society

Mosque is not just a place of worship for Muslims; it’s the common most place of meeting and congregation of the followers of the religion of peace, Islam. It’s not only a holy place; it helps spread the message of love, friendship and brotherhood. Mosque is not merely a place that involves spirituality but also deals with worldly affairs; It’s more than that.

Read More

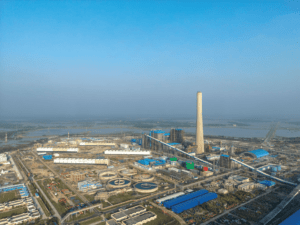

Rampal Coal-fired power plant – A Major Solution to Bangladesh’s Power Crisis

Bangladesh is at an unprecedented crossroads with power crisis and hyper inflation. At a time when major industries at home suffer an acute power crisis, aggravated by the the Russia-Ukraine war following the Covid-19 pandemic, the recent soft inauguration of the first unit of the 1,320-megawatt Maitree Super-Thermal Power Project, also known as Rampal Power Plant, is believed to have been a relief from the energy crisis. Amid the crisis globally, Bangladeshi stakeholders, especially those involved with the multi billion-dollar export industries, manufacturing sector and the financial sector, are now waiting wholeheartedly for commercial operation of the Rampal Power Plant soon to rid the nation of this power predicament. Domestic energy experts and analysts alongside other stakeholders look optimistic with this project and they are of the opinion that the Rampal power project is economically feasible, sustainable and profitable. Terming it one of the cheapest power plants of its kind in the country, they strongly viewed that the plant will get going with the key objective of generating affordable electricity as a resilient and viable solution to the country’s power crisis. Prime Minister Sheikh Hasina and her Indian counterpart Narendra Modi jointly inaugurated the first unit of the coal-fired super-thermal plant through video conferencing on September 6, 2022. The country’s largest power plant is sited on an area of more than 915 acres of land in Rampal upazilla in south-western Bagerhat district under Khulna division, some 272 kilometres away from the capital Dhaka. The high-efficiency, low-emission supercritical plant site sits 14 kilometres north of the world’s largest mangrove forest, the Sundarbans. About the funders The Rampal power project is a joint venture between India’s state-owned National Thermal Power Corporation (NTPC) Ltd and the state-owned Bangladesh Power Development Board (BPDB). The US$ 2.00 billion joint venture company is known as the Bangladesh-India Friendship Power Company Ltd. (BIFPCL) that builds, runs and operates this power facility. The BIFPCL has been co-promoted by the BPDB of Bangladesh and the NTPC Ltd of India with an equal (50:50) equity investment. According to Bangladesh’s power ministry, the joint venture company will enjoy a 15-year tax holiday. In March 2022, Bangladesh boasted the country’s access to 100 per cent electricity, but the national power grid system failed in July and power outage suddenly began to disturb the nation and the socio-economic activities. The Power Division disclosed that the largest amount of what is technically called load-shedding per day stood at 2,000–2,200 MW during the July-September period. But this shortfall peaked in October, taking it to 2,500–3,000 MW. The start of the project BPDB and NTPC entered into a memorandum of understanding (MoU) instrument in 2010 to implementing this mega power plant project in Bagerhat’s Rampal upazilla that has seen an upturn in economic activities centring this power plant in recent years. An estimated 80 per cent of the project costs will be covered through a long-term loan from the EXIM Bank of India. As the construction of the facility was ongoing, the February 2021 was set as the first deadline for commissioning the power plant’s first unit while the second unit by August 2021, according to competent sources. However, the deadline was extended several times for a number of reasons, including emergence of the Covid-19 pandemic in 2020. Use of coal and technology A coal-fired plant produces electricity by burning coal in a boiler to produce steam. Then the steam, produced under tremendous pressure, flows into a turbine, which spins a generator to create electricity. The steam is then cooled, condensed back into water and returned to the boiler in order to start the process over. Supercritical combustion technology and sophisticated equipment are being used to lessen environmental hazards and thus make this project safe and eco-friendly. Some 6,500 cubic meters of water will be required per hour and minimum 10,000 tonnes of coal will be required to produce 1300 MW electricity every day. The ash content of this imported Indonesian coal is 8-10%. The height of chimney is 275 meters, equivalent to 90 storied building. In its initial stages, there was a strong debate on the red-hot issue of installing this coal-fuelled thermal power facility near a forest and some termed it suicidal with apprehensions of environmental disaster for the forest, which is home to thousands of wild species, flora and fauna. Some environmentalists made a mass call for scrapping of the project. The government, however, showed its determination to go ahead with the project. State energy experts said the project would not be harmful as its supercritical technology will minimise ecological hazards. Eco-warriors demanded that environmental concerns must be given precedence over commercial interest. They called for doing an environmental impact assessment and feasibility study before embarking on the project that may have anthropogenic impacts on environment, including effects on biophysical environments, biodiversity and other resources, let alone emissions of carbon dioxide and other pollutants as well as particulates. The joint venture company has already planted 116,000 different kinds of trees around the project site while the Centre for Environmental and Geographic Information Services (CEGIS) is monitoring the parameters related to the environment of the Rampal site and its adjacent areas, including Khulna and the Sundarbans. Employment opportunities The Rampal power plant project has opened up a job generation opportunity for local people and those affected for construction of this project’s infrastructure and during its operational period. As this region has long remained underdeveloped, opportunity of trade and employment was very limited. The power plant project has come as a relief to some extent. Alongside direct employment in the BIFPCL, there will be a huge opportunity to the locals for business and other indirect employment prospects. Moreover, this industry will usher in economic growth in Rampal in particular and the country in general, creating many downstream and/or related industries. Supply chain The supply chain of coal in all coal-fired power plants, including the Rampal power plant, is the biggest challenge. Technically unique in the plant is the supply chain issue. The Rampal

Read More

A Bridge From Transport Connectivity to Economic Corridor

The opening of the Padma Bridge has created the scope for a new wave of investment in the country’s south and south-western region. The region’s easier road communications with the rest of the country has brought fresh momentum for business growth. New industries are being planned and tourism sector entrepreneurs are hoping for a business boom surrounding Kuakata sea beach and the Sundarbans. Thus, the bridge has offered a new economic corridor in the making. Economists and business leaders believe with remarkable improvement in road network though the bridge trade and business in the region would expand rapidly, raising the people’s income, creating jobs and eradicating poverty. The Padma Bridge is also expected to bring about a massive change in the entire economy. The Ministry of Road Transport and Bridges believes the economic corridor surrounding the Padma Bridge and its adjacent areas would increase the country’s GDP (gross domestic product) growth by 1.27 percentage point. The southern region’s economy will grow at a higher pace. Predicting a higher GDP growth for the Padma Bridge, the Asian Development Bank (ADB) said the rate of poverty reduction will be accelerated by 0.84 per cent every year. However, as many as 53 upazilas out of 133 upazilas in 21 districts on the south-western side of the bridge are of high concentration of poverty, according to Bangladesh Bureau of Statistics (BBS) poverty map. Another 42 upazilas are in the medium poverty risk category and 38 in low poverty risk category. Economist and chairman of Palli Karma-Sahayak Foundation (PKSF) Quazi Kholiquzzaman Ahmad said small entrepreneurs are more enthusiastic about the Padma Bridge and they should be provided with opportunity to make investment and various supports such as gas and electricity supply should be ensured at affordable costs. He observed that the bridge has jointed the southern belt with the rest of the country. The bridge will result in smooth transportation of farm produces from the region, according to Implementation, Monitoring and Evaluation Division (IMED) of the Ministry of Planning. It said farmers’ income will increase 15-20 per cent since direct connections between farmers and the market forces will be established. Transport sector insiders added the time for transportation of goods from Benapole to Dhaka would come down to 6-7 hours from 24-36 hours. The southern region was attractive for low-cost transport of goods by river routes but longer time and uncertainity in ferry services earlier discouraged the entrepreneurs from taking business initiatives. The Padma Bridge has now created the scope for big companies to come forward with investment projects in the region. The companies that have shown interest in setting up factories in the region include Sheltech, Pran-RFL, TK Group, Envoy Group, Hameem Group, Mir Group, Karim Group and Opsonin Pharma. Bangladesh Economic Zones Authority (BEZA) has unveiled a master plan on Padma Bridge that would directly benefit Dhaka, Khulna and Barisal divisions. It is taking steps to establish 17 new Economic Zones (EZ) in 21 districts of the three divisions. In the 1960s, Khulna became one of the few industrial hubs of the country but it has subsequently lost the glory. However, after the launch of Padma Bridge, Khulna is drawing attention of the investors. Abdus Salam Murshedi MP, president of Bangladesh Exporters’ Association (BEA) and former president of BGMEA said, “I definitely want to use this opportunity. I want to set up a new garment factory in Khulna. I also encourage others to invest in the region.” In fact in 2019, Sheltech Group established the country’s largest ceramics industry in the southern district of Bhola. The company invested more than Tk 7 billion taking advantage of local natural gas and cheap land with the hope of opening of the Padma Bridge in 2022. Now, Sheltech is also planning to set up a non-denim garment factory in Bhola, said Engineer Kutubuddin Ahmed, chairman of the group. “We are now looking for land to set up a ready-made garment industry in Barisal. After the inauguration of the Padma Bridge, investing in the south is the most promising one,” he added. Chini Tikri The Inaugural Murals By 15,000 Ceramic Plates One of the two spectacular installations at each end of the Padma Bridge is its inaugural mural – which has been constructed by using 15,000 ceramic plates. The portraits of Father of the Nation Bangabandhu Sheikh Mujibur Rahman and Prime Minister Sheikh Hasina have been made by breaking these 37 coloured plates into ‘Chini Tikri’. One was the dreamer of Padma Bridge and the another one is its implementer. As the ceramic plate is broken and made, it starts to sparkle when the sun shines on it. These ceramic plates are hammered and broken into about half a million pieces. Then different colours of the pieces are arranged one after one to create two beautiful portraits. Designed by architect Fazle Karim Shishir of Drishik, the two murals were created by artists Ashraful Alam Riaz and Didar Ul Alam. Both are graduated from the Fine Arts Institute of Dhaka University. The 90-feet-long and 45-feet-high mural at the Mawa end was done by Didar Ul Alam and the 72-feet-long and 36-feet-high mural at the Janzeera end was done by Ashraful Alam Riaz. They told Ceramic Bangladesh that at first the designer thought of making this mural with ceramic tiles, but later they chose ceramic plates of the highest quality considering the bright colour and durability. A total of 15,000 plates of 37 types of colours have been used here. Among them, 7 types of coloured plates are used to display black and white portrait of Bangabandhu. And 30 types of coloured plates are used to produce colourful portrait of Prime Minister Sheikh Hasina. All of these ceramic plates are customised. Because such a variety of colour plates are not usually produced by ceramic companies. Artisan Ceramics made 8,000 plates used in the Mawa end mural and Monno Ceramics made 7,000 plates used in the Janzeera end mural. This construction work was completed in two months by two

Read More

Metro Rail A Reflection of a New Dhaka

Metro Rail will make Dhaka closer to people living in its immediate vicinity. It will change the landscape of the metropolitan city of 20 million people. It will also change the demography in a city where 45,000 people live in per square kilometer area. Motijheel was called the heart of the Dhaka city but thanks to Metro Rail, each station is being developed as a single heart. So, centering the ‘Mass Rapid Transit’ MRT-6 route’s 17 elevated stations, residential and commercial areas are undergoing major changes. Currently, it takes two hours to travel from Uttara to Kamalapur station; the Metro Rail service will bring that down to 40-45 minutes only. During peak hours, the $3 billion Metro Rail will be able to transport around 1800 passengers on each direction in every three and a half minutes on this route, resulting in an average reduction of 15 buses and 100 different types of vehicles on each direction. Traffic congestion is also expected to be reduced and huge working hours will be saved. As per the Minister of Road Transport and Bridges, Mr. Obaidul Quader, five more Metro Rail-routes will be constructed in Dhaka by the year 2030 when the face of Dhaka will change. It will cost about US$ 22 billion. On June 26, 2016, Prime Minister Sheikh Hasina officially inaugurated the construction work of the MRT-6 project. This marked the beginning of the construction work of the Elevated Metro in Dhaka. The elevated Viaduct on which the Trains will run is about 13 meters above the ground. In Dhaka, out of 17 stations on the 21-km-long MRT-6 route, construction of a 12 km railway track from Uttara to Agargaon and construction of 9 stations is nearing completion. Under the construction package CP-3 and CP-4, the stations are Uttara North, Uttara Center, Uttara South, Pallabi, Mirpur-11, Mirpur-10, Kazipara, Shewrapara and Agargaon. The plan to inaugurate the service along this section has been set for December 16, 2022. Each Metro station has a 180 meters long and 25 meters wide Concourse Hall. Passengers will use the stairs, escalators and elevators to purchase/recharge MRT Pass or Rapid Pass from the Concourse Hall and then board the Train from the Platform located above it. Each of these three-storied stations is built on an average 200,000 square feet area. Most of the materials used for constructing these stations have been procured locally. One of which is the use of different types of Tiles. These tiles include floor tiles, wall tiles, glass tiles, tactile tiles (for passengers with special needs), brick claddings for walls, paving blocks for platforms, and stone tiles. And these are special types of vitrified tiles made of high temperature, which do not corrode easily. Only 5 companies in the country are considered eligible to supply these tiles. About 50% cost has been saved due to the use of products manufactured locally. Metro Rail will require about 18 megawatts of electricity to be taken from the national grid. Then it will be converted to DC electricity. For this, eight Traction substations have been installed in Uttara Depot, Uttara North, Uttara South, Mirpur-11, Shewrapara, Bijoy Sarani, Shahbag and Motijheel Stations. The cost of operation and maintenance for Metro Rail is yearly one thousand crore taka will be borne from the fare and other sources such as rental/leasing of commercial and advertisement spaces. The government is thinking about keeping the fare affordable for passengers from all walks of life with subsidies at first. The ministry of Road Transport and Bridges gave an impression that the fare may vary between a minimum of 20 Taka to 100 Taka depending on the length of the journey along the 21-km route. There will be various announcements for passengers in Metrorail in both Bangla and English. From uttara to kamalapur Metro Rail from Uttara to Kamalapur will take about 45 minutes. Although the highest design speed of the Metro Train is 110 kilometers per hour, the actual speed may vary due to the curves on the route and other operating factors. 17 stations in 21 kilometers mean each of the stations are located within one and a quarter kilometers from another. The Trains may stop for a maximum of one minute at each station. During peak hours, trains will run every three and half minutes apart. An estimated 60,000 passengers will be able to commute on both directions per hour from early morning to midnight. Once fully completed, 24 sets of Metro Trains will run from Uttara to Kamalapur. However, 12 sets out of those will be used for the first phase operation from Uttara to Agargaon. Initially each of these trains will have six coaches with an option of adding two more coaches to each of the Train sets if necessary. Each Train will have a total seating and standing maximum capacity of 2,308 passengers. According to this calculation, at the beginning, it will be possible to transport about half a million passengers per day. One of the six coaches on each train will be reserved for women. However, other coaches of the train will also allow men and women to travel together. MRT Line-6 was initially planned to reach Motijheel, but later it was extended by 1.16 km to reach Kamalapur Railway Station. Though, physical work for the extension of Motijheel to Kamalapur section has not started yet, the preparatory works for this extension is ongoing in full swing. In addition to MRT Line-6, 3 other Metro Rail routes (MRT Line-1, MRT Line-4 & MRT Line-2) will also have stations adjacent to the Kamalapur Railway Station. Once completed Kamalapur Railway Station will transform into a modern transit hub. Even though, initially, the timeframe to complete the MRT Line-6 project up to Motijheel was set for 2024, Bangladesh Government is keen to complete the project ahead of that target. If the current pace of work remains unchanged, hopefully, the people of Dhaka will get the much awaited MRT Line-6 by December 2023. Minister Obaidul Quader said

Read More

History

The growth of the ceramic industry can also be attributed to historic back ground of the country, especially the people’s choice for attractive tablwares and show pieces. Records say, potters were actually popularised during the zamindars (landlords). They used to be patronised for making staues of goddesses, plates and other aesthetical items. Sometimes they were made to sculpt statues of the zamindar themselves. After the end of the zamindar system, they started making everyday household items for sales in the local market to earn a living. As pottery was the tradition, a section of people called kumar (potters) had for generaions embraced the occupation of making pottery items of household use. Their hand-made products could catch interest of the rural buyers. However, these proucts could neither meet demand of urban customers nor could they sustain because of their fragility, sun or oven baked products could not make a big headway outside the country. Recent history shows it was the initiative of an entrepreneur in the late 1950s that began production of earthen-ware using machine and thus machine-made clay craft appeared in the market. In fact, modern ceramic industry (machine-made) took a formal start with the functioning of Tajma Ceramic industry in Bogra in 1958. It was a small plant for porcelain tableware, and so production capacity of the factory was limited. Then came other entrepreneurs. The next to come was Mirpur Ceramic Works in 1962. Then Pakistan Ceramic Industry (later People Ceramic Industry) joined the market in 1966. After a gap of nearly two decades Monno Ceramics started production (tableware) in 1985. In the following year Bengal Fine Ceramics came to the scene. In 1997 Shinepukur Ceramics started production. As more entrepreneurs stepped in, they startd producing diversified items such as tiles, sanitary ware adopting new technology and using latest machinery and fine clay brought from abroad. Bangladesh Insulator and Sanitaryware Factory (BISF), Modhumoti Ceramics, Fu Wang Ceramic Industries and RAK Ceramics have placed themselves at the front in production of the items, not traditional, like tea-set or dinner sets. According to available statistics, about 95 per cent of raw materials for producing items are imported from different sources to maintain standards. The raw materials are imported mostly from China, Japan, Germany, New Zealand, Australia, Italy, Spain, Bulgeria, Vietnam, Thailand, South Korea and India. LOCAL CERAMIC INDUSTRY This is an industry that has experienced 200 per cent growth in production in the past ten years. Currently, there are 66 ceramic plants in three categories (Tableware 20, Tiles 28 and Sanitary ware 18) of products, operational in the country. Their products range. from table wares to tiles, sanitary wares to insulators and heavy and from clay to reflectors. The number of firms increased from 29 in 2010 to 66 in 2019. Investment in the sector amounts to more than US$1.1 billion, according to the Bangladesh Ceramics Manufacturers and Export- ers Association’s (BCMEA’s) estimate. More than half a million people, 40 percent of who are women, are directly and indirectly involved in the ceramic industry. Given the growth and demand of the sector, there has been a national focus on building skilled human resources for the ceramic industry. Now, Bangladesh Institute of Glass and Ceramics, Depart- ment of Glass and Ceramic Engineering at BUET and Rajshahi University of Engineering and Technology, and Faculty of Fine Arts at Dhaka University, offer various courses relating to ceramic products. The base of the industry is strong as the sector caters to 85 percent of the local demand and around 90 per cent of its 2018 turnover of Tk. 60 billion involved domestic market. The sector has seen a phenomenal local market growth from Tk 1225 billion in FY2010 to Tk 53.38 billion in FY2017. The industry’s production growth was record- ed at around 30 per cent in the past ten years. The country’s ceramics industry has also attracted foreign investments that have mainly come from China and the Middle-East countries. One foriegn and six joint venture companies include RAK Ceramics, Fu-Wang and China-Bangla Ceramics. Exports of ceramic products Although the country’s export volume is still not high in comparison to potential, about 20 companies are currently exporting ceramic products with 65 per cent value addition, according to available information. An amount of Tk. 4801 million came from the export market in 2018. It has maintained average 18 per cent growth in last 10 years. The sector attained a 32 per cent export growth in the year after the previous year’s growth of 16.6 per cent. The export market of ceramic products covers 63 countries. Main export destinations are EU countries, USA, Canada, New Zealand, Australia, Turkey and the Middle East. Industry insiders say the demand for Bangladeshi ceramic products in the international market is strong and there is reasonable scope for increasing exports of ceramic items. China and India are among major competitors in the international market for Bangladeshi ceramic manufacturers. However, labour cost has put Bangladesh in a strong position. Bangladeshi exporters can enhance exports if they are provided with supports to become more competitive in the international market. Given the global market of ceramic products worth US$400 billion, Bangladesh’s ceramic industry, if proper plans are taken and executed, has the potential to emerge as the ‘next RMG industry. Bangladesh’s expport share of the global ceramics market is less than 0.10% CHALLENGES AND WAY FORWARD Industry leaders say the country’s ceramic industry is facing some challenges, that are constraining its growth at home and in the export market. Of course, there is a scope for improve the production process making it more energy efficient. For that more funds need to be injected into the sector. Use of Nano-technology could be a good choice for entrepreneurs in Bangladesh. However, uninterrupted supply of natural gas, which is the main energy source for the industry, is a prerequisite for increasing production, according to sector leaders. Bangladesh’s domestic market for ceramic products is expanding due mainly to quality of products and price competitiveness. So supports should be

Read More