Partners Regular

Mir Ceramic Launches Premium Tiles Brand CLIO in Bangladesh

Mir Ceramic Limited has entered a new phase in Bangladesh’s ceramic industry with the launch of its premium tiles brand, CLIO, positioning it as a symbol of sophistication and modern living. Guided by decades of trust and the philosophy “Be with the Best,” CLIO debuts with the tagline “The Ceramic of Modern Living.” The brand was officially launched at a grand ceremony held at the Pan Pacific Sonargaon Hotel in Dhaka, on the evening of Saturday, January 31. The event was graced by the presence of Mir Ceramic Limited’s Honorable Managing Director, Mr. Mir Nasir Hossain; Deputy Managing Director, Mr. Ruslan Nasir; Director, Ms. Mahreen Nasir; and Executive Director, Mr. Md. Anisur Rahman. The chief guest of the program was Md. Khalequezzaman Choudhury, Chief Engineer of the Public Works Department (PWD), and a Fellow Member of the Institution of Engineers, Bangladesh (FIEB). The Special Guests included Emeritus Professor Dr. M. Shamim Z. Bosunia and Bangladesh Ceramic Manufacturers & Exporters Association (BCMEA) President Mr. Moynul Islam, Md. Asifur Rahman Bhuiyan, Chief Architect, Department of Architecture, Bangladesh. According to Mir Ceramic Limited, CLIO aims to redefine conventional concepts of interior design by offering timeless, contemporary tile solutions that reflect creativity and confidence in modern lifestyles. As a special attraction of the evening, the official unveiling of CLIO – including its logo and products-was carried out through a laser show. The program concluded with a musical performance by popular singer Dilshad Nahar Kona. With the launch of CLIO, Mir Ceramic Limited reaffirmed its commitment to delivering innovative, aesthetically refined, and globally inspired ceramic solutions to Bangladeshi consumers. Source: Mir Ceramics

Read More

AkijBashir Group Signs Strategic MoU with Envisio Group

AkijBashir Group and Envisio Group have signed a significant Memorandum of Understanding (MoU), marking the beginning of a strategic collaboration aimed at expanding the reach of AkijBashir’s premium product portfolio. The MoU was signed on January 18th, 2026 by Mohammod Khourshed Alam, Chief Operating Officer of AkijBashir Group, and K M Sumon, Managing Director of Envisio Group, in the presence of senior officials from both organizations. Under the terms of the Memorandum of Understanding (MoU), Envisio Group will feature AkijBashir’s leading brands—Akij Ceramics, ROSA Sanitaryware & Bathware, Akij Board, Akij Door, and Akij Glass—offering customers a complete solution for tiles, sanitaryware, bathware, boards, doors, and glass products. Both companies will collaborate on marketing initiatives and leverage each other’s brand presence to reach new customers, strengthening both companies’ positions in the competitive building materials sector. Mr. Khourshed Alam expressed, “This collaboration aligns with our goal to deliver world-class building materials and enrich modern living experiences for our customers across Bangladesh, while reinforcing our commitment to innovation and excellence.” Alhaj Md. Mazharul Islam, Chairman of Envisio Group, added, “This collaboration with AkijBashir Group allows us to provide our customers with an even broader selection of top-tier products, enriching their living spaces with quality and sophistication.” Notable attendees from the AkijBashir Group included Mohammed Ashraful Haque, Head of Sales at Akij Ceramics, Bishwajit Paul, Head of Sales at ROSA Sanitaryware, and Abduhu Sufi, Head of Sales at AkijBashir Glass, along with other senior team members from both organizations, who were also present to witness the signing. The alliance marks a new chapter for both organizations, united in their pursuit to shape elegant, sustainable, and inspiring spaces—Beyond Tomorrow.

Read More

Leading Without Pause: Akij Ceramics wins Seventh Consecutive Best Brand Award

For the seventh consecutive year, Akij Ceramics has been honoured with the prestigious Best Brand Award 2025, a milestone that reinforces the brand’s unmatched leadership and enduring consumer trust in Bangladesh’s ceramic tiles industry. True leadership is defined not by a single achievement but by the ability to sustain excellence. In a rapidly evolving and competitive market, Akij Ceramics has consistently stayed ahead—setting the benchmark through uncompromising quality, continuous innovation, and a deep understanding of consumer expectations. Since first receiving the Best Brand Award in 2019, the brand has steadily strengthened its bond with consumers nationwide. Anchored in its guiding philosophy, “Promise of Perfection,” Akij Ceramics delivers products that seamlessly blend advanced technology, refined aesthetics, and dependable performance—shaping spaces with confidence and distinction. Organised by the Bangladesh Brand Forum, the Best Brand Award is among the country’s most credible recognitions, determined through extensive consumer research and expert evaluation. Earning this honour seven times in a row underscores the brand’s consistency, credibility, and influence within the industry. This exceptional consistency is further validated by the brand’s recognition as a “Superbrands” award winner for two terms (2023–24 and 2025–26), reaffirming Akij Ceramics’ position as one of the most trusted and admired brands in the country. As Akij Ceramics celebrates this landmark achievement, the brand remains focused on raising the bar even higher—driving innovation, elevating quality standards, and continuing to lead the ceramic industry with clarity, confidence, and purpose.

Read More

Akij Board has won the Best Brand Award for two consecutive years in the Board Category

Akij Board has once again been honored with the Best Brand Award in the Wooden Board category at the Best Brand Awards 2025, marking its second consecutive win and reaffirming its position as the defining leader of the category since its inception. As the inaugural winner when the category was first introduced, Akij Board continues to set the benchmark for excellence, innovation, and customer empowerment in Bangladesh’s board industry. Organized by the Bangladesh Brand Forum, the Best Brand Awards honor brands that demonstrate consistent leadership, strong consumer trust, and long-term impact. Through a rigorous evaluation process based on consumer insights and expert analysis, Akij Board once again emerged as the standout choice, reinforcing its leadership in the Wooden Board category. Driven by its empowering philosophy, “Now You Can,” Akij Board has consistently expanded the boundaries of what is possible in surface solutions. From advanced technologies and refined finishes to a diversified portfolio of premium boards, the brand enables designers, craftsmen, and homeowners to translate vision into reality with confidence and creativity. This sustained recognition reflects Akij Board’s commitment to evolving with customer needs while shaping industry standards rather than following them. By combining reliability, performance, and forward-thinking design, the brand has transformed boards from functional materials into enablers of modern living and architectural expression. Winning this award for the second consecutive year underscores Akij Board’s role as the brand that defines the category it leads. As the journey continues, Akij Board remains focused on unlocking new possibilities, driving innovation responsibly, and staying true to its promise that with Akij Board, Now You Can.

Read More

Akij Tableware Hosts the First Ever Business Conference in Bangladesh’s Tableware Industry

Akij Tableware, a proud concern of AkijBashir Group, has made history by hosting the first-ever business conference in Bangladesh’s tableware industry. The landmark event, titled “Akij Tableware Evolve Beyond Business Conference 2025,” was held on 19th December 2025 at the Ocean Paradise Hotel and Resort in Cox’s Bazar. The conference brought together around 150 participants, including nationwide business associates, senior management, and members of the Akij Tableware team. It created a meaningful platform to strengthen partnerships, celebrate success, and set the direction for the future of one of the country’s fastest-growing tableware brands. In an industry where large-scale strategic gatherings are rare, Akij Tableware’s initiative set a new benchmark for collaboration and leadership. The conference underscored the brand’s commitment to building a stronger and more future-ready distribution ecosystem across Bangladesh. Throughout the day, attendees engaged in strategic discussions and product showcases that demonstrated Akij Tableware’s continuous growth and innovation. Chief Operating Officer (COO), AkijBashir Group- Mohammod Khourshed Alam; General Manager, Sales and Marketing, Akij Tableware- Md. Mahbubur Rahman; General Manager, Production, Akij Tableware- Engr. Zayedur Rahman; Director, Productions, Akij Ceramics- Md. Saidur Rahman Khan & Deputy General Manager- Md. Shahriar Zaman shared their insights and future outlook, alongside other managerial bodies and employees who contributed their perspectives to align the brand’s collective vision. Set against the stunning backdrop of Cox’s Bazar, the conference offered an unforgettable blend of strategic reflection, learning, and celebration. For many attendees, it became a memorable milestone and a symbol of Akij Tableware’s evolving journey. With the success of its first-ever Business Conference, Akij Tableware is now poised to “Evolve Beyond” as it enters a new era of growth, strengthened partnerships, and enhanced market presence nationwide – continuing its commitment to bringing out the best in quality, design, and customer experience.

Read MoreAkijBashir Group Opens New “Selections” Showroom at Banglamotor

AkijBashir Group has opened a new Selections showroom at Banglamotor, Dhaka, expanding its network of outlets that offer building-material solutions under one platform. Launched in October 2022 with the motto “Select from the Best,” Selections now operates seven flagship outlets across Dhaka, Chittagong, Sylhet, Savar, Tangail, and Kishoreganj. The newly opened Banglamotor showroom, located at 18 Link Road, features a range of ceramic tiles, boards, doors, sanitaryware, bathware, and tableware – representing the complete product lineup of AkijBashir Group brands. The showroom was inaugurated by Mohammod Khorshed Alam, Chief Operating Officer of AkijBashir Group. Senior officials present included Mohammed Ashraful Haque, General Manager (Sales) of Akij Ceramics; Bishwajit Paul, Head of Sales at ROSA; and Md. Hasan-Ur-Rashid, proprietor of Yasir Trade Corporation. With the opening of the Banglamotor outlet, Selections continues its expansion, offering customers improved access to its building-material categories and a convenient selection experience.

Read More

Akij Board & Akij Door Host Business Conference 2025 at Nepal

Akij Board and Akij Door, two leading brands of AkijBashir Group, made history by successfully hosting the Evolve Beyond Business Conference 2025 on November 11, 2025, at the iconic Soaltee Hotel in Kathmandu, Nepal – marking the first time in Bangladesh’s board industry that a dealers conference was held beyond national borders. The event brought together more than 370 business associates, dealers, and representatives from across the country, creating an atmosphere of unity, pride, and celebration. Amid the breathtaking Himalayan landscape and Nepal’s serene charm, participants experienced an unforgettable blend of strategic discussions, cultural exploration, and joyous moments. The cool mountain air, picturesque surroundings, and warm Nepali hospitality made the event not only a milestone in business history but also a lifetime memory for everyone who attended. Continuing the legacy of last year’s “Evolve Beyond” theme, the 2025 edition inspired participants to push boundaries, embrace innovation, and envision greater growth. The conference served as a dynamic platform to align future business goals, strengthen partnerships, and celebrate the collective achievements of Akij Board and Akij Door’s nationwide network. The event was graced by the presence of Chief Operating Officer Khourshed Alam, Accounts and Finance Director Mohammad Zahid Hossain, Head of Sales Md. Nazrul Islam, Head of Production Sk. Zakaria Nashim, along with senior officials from various departments of the organization. Their inspiring addresses motivated participants to continue striving for excellence and to take pride in being part of Akij Board & Akij Door’s promises. A key highlight of the event was the unveiling of three groundbreaking products – SYNCHRO, FiberCem, and Ultimatt. Synchro is a premium textured board with perfectly matched designs that mimic natural materials called Synchronized Melamine Board. FiberCem is a high-performance fiber cement board offering exceptional strength and versatility for interior and exterior use. And Ultimatt is a revolutionary super-matt, silky-touch, anti-fingerprint surface ensuring superior durability, scratch resistance, and colour stability. Together, these innovations reaffirm Akij Board’s leadership in advanced, design-driven surface solutions. The conference concluded with a spectacular cultural gala night filled with music, laughter, and celebration, a fitting finale to an event that perfectly blended business vision with unforgettable experiences. As Akij Board and Akij Door Evolve Beyond Business Conference 2025, Nepal Edition came to an end, it reaffirmed that Akij Board and Akij Door stand stronger than ever – ready to evolve, lead, and shape the future of the industry with innovation, partnership, and passion.

Read More

Akij Ceramics Opens Exclusive Showroom in Savar’s Hemayetpur

Leading tiles brand Akij Ceramics has opened a new exclusive showroom in Savar’s Hemayetpur, bringing its signature craftsmanship and contemporary designs closer to customers. Located on Singair Road, the new outlet — Usha Sanitary & Tiles House — offers an enhanced retail experience with immersive displays, modern layouts, and a curated selection of Akij Ceramics’ finest collections. Mohammad Khourshed Alam, Chief Operating Officer of Akij Bashir Group; Mohammed Ashraful Haque, General Manager (Sales) of Akij Ceramics Ltd; and Md Abul Khayer, proprietor of the showroom, attended the inauguration ceremony on October 12 alongside senior officials of the group. A six-time Best Brand Award and two-time Superbrands Award winner, Akij Ceramics continues to champion innovation, design excellence, and customer trust — staying true to its timeless promise, “Promise of Perfection.” With this expansion, Akij Ceramics reinforces its vision of transforming everyday spaces into expressions of elegance, quality, and modern living. Written By Nibir Ayaan

Read More

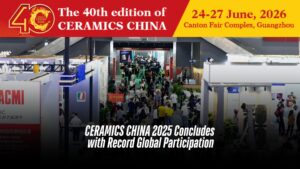

CERAMICS CHINA 2025 Concludes with Record Global Participation

CERAMICS CHINA 2025, the world’s leading trade fair for ceramic equipment and materials, successfully concluded on June 21st in Guangzhou, marking an exceptional edition characterized by unprecedented international engagement and vibrant business exchange. The event solidified its position as the indispensable global marketplace for innovation, collaboration and networking across the entire ceramics value chain. This year’s exhibition achieved remarkable scale and reach, attracting 786 outstanding exhibitors from 21 countries and regions, including mainland China, Belgium, Germany, France, Korea, Malaysia, Japan, Slovenia, Turkey, Spain, Italy, India , Indonesia, UK, Vietnam, Bangladesh, Russia, USA, Brazil, Taiwan China and Hong Kong China. The extensive participation validated the exhibition as a truly global microcosm showcasing advanced products, cutting-edge technologies and innovative solutions spanning intelligent production equipment, eco-friendly materials, digital manufacturing processes and end-to-end service system. The exhibition highlighted three defining trends within the ceramic industry development: the comprehensive AI-driven intelligence integrated throughout production workflows to enhance efficiency and strengthen quality control; the sprouting compact equipment designed for eco-friendly operations, cost reduction, and flexible manufacturing; the cross-sector diversified expansion dominated by traditional equipment manufacturers to cultivate sustainable market growth in different sectors. The evolving products and technologies showcased on-site also gave visitors insights into the latest industry trends and market dynamics, informing their purchasing decisions and strategic planning. From June 18-21, CERAMICS CHINA 2025 welcomed totally 80,240 visits of industry professionals from 94 countries and regions in the 4-day exhibition. Key visitor delegations this year represented major manufacturing hubs, industry associations, leading ceramic manufacturers and import/export giants. The expansive participation this year signified a significant leap in the global influence and appeal of the event. Building on the record participation and vibrant exchange of CERAMICS CHINA 2025, the highly anticipated next edition is now scheduled for June 24-27, 2026, in Guangzhou, where the global ceramics community will reconvene to build on this momentum and drive further industry advancement.

Read More

Ceramica Alberdi kickstarts a new ceramic manufacturing era with SACMI Continua+

Winner of ‘best new ceramic plant in South America’ at the Tecna Awards 2024, the company has introduced two new Continua+ lines to manufacture ultra-high quality products: an ambitious project that aims to build a smart, sustainable ceramics factory, with SACMI providing all the key production technologies Ceramica Alberdi has selected SACMI Continua+, installing – for the first time in South America – two parallel lines for the manufacture of ultra-high-quality slabs and tiles. Founded in 1907 and based in José C. Paz near Buenos Aires, the company has always been at the forefront of innovation: now, with this project, it’s taken another huge technological leap forward. The supplied plant, the first of its kind in South America, consists of two Continua+ presses (PCR 2120 model) operating in parallel to feed a single drying, glazing and firing line. Alberdi has taken a bold step here and has, with this new plant, targeted a specific segment: thin tiles and slabs (6 mm thick) that combine outstanding quality, practicality and aesthetics with low environmental impact, also significantly reducing the transportation costs of the finished product. A smart, high-quality ceramic plant that requires less energy, reduces handling/storage costs and streamlines installation: to build it, the only realistic choice was the PCR 2120, the compact ‘smart’ version of the SACMI Continua+ that delivers outstanding flexibility and productivity with the market’s most popular slab sizes (1200×2400, 600×1200 and related sub-sizes). In addition to the two Continua+ presses, SACMI supplied all the other key plant technologies, from body preparation – a new ATM140 spray dryer and a MMC 120 modular mill – to the new 5-tier dryer. Completing the order, the 300-meter-long FMA Maestro kiln offers a modulated air-gas solution with cutting-edge features that reduce consumption and emissions and retrieve heat to maximize efficiency. In this configuration – and thanks to the dual Continua+ line – Ceramica Alberdi has boosted plant productivity to over 25,000 square meters per day on all sizes, with a sharp focus on manufacturing extremely high-quality products to keep ahead of market trends. This outstanding inventiveness saw the company awarded the prestigious Tecna Award at the Tecna trade fair for ‘best new ceramic plant in South America’. The award acknowledges the company’s recent investments in technology that have allowed it to excel in terms of product and process innovation, strengthening its leadership on the Argentinian floor and wall tile market.

Read More

“Timber Tales” sparks a dialogue in wood and ink

The ongoing exhibition titled Timber Tales at La Galerie, Alliance Française de Dhaka, invites audiences to experience the collaborative journey of three emerging artists who explore memory, process, and material through the art of woodcut printmaking. Within the exhibition, a faint, earthy scent of wood and ink hangs in the air. Walking into the gallery, some might find themselves pausing longer than expected, tracing the grain of the wood, as if searching for their own stories between the lines. The exhibition features three artists—Rakib Alam Shanto, Shakil Mridha, and Abu Al Naeem—who express individuality through their woodcut prints. This contemplative exhibition is running from June 17 to June 25, 2025. Curated by the artists themselves, the exhibition reimagines the possibilities of woodcut as a medium. Here, the tactile intimacy of carved timber meets the visual language of reflection, nostalgia, and search. As you wander through the space, individual voices emerge. Shakil Mridha’s work, with its minimalistic yet profound geometric forms, feels like a contemporary ode to Bangladeshi folk art, skillfully abstracting familiar motifs. Rakib Alam Shanto’s large-scale black and white pieces command attention, a powerful revival of a classic tradition, showcasing his remarkable focus. And Abu Al Naeem’s pieces, often abstract, subtly reveal hidden figures, reflecting his continuous exploration of materials and techniques. Each artist, in their unique way, elevates woodcut beyond mere reproduction, transforming it into a medium of profound personal expression. And through that expression, each of their work reflects the heart of the creative process, where stories are carved into existence. At the heart of Timber Tales is a tribute to beginnings, to the mentor who shaped them, and to the space where it all began. Their acknowledgement of Professor Md. Anisuzzaman, whose generous guidance helped steer their vision, reveals the deeply collaborative ethos of the show. “This is where it all began—for the three of us,” reads a line from the exhibition note, underscoring the intimate bond between craft, community, and coming-of-age. In an era of digital immediacy, there’s something revolutionary about the deliberate slowness of woodcut. And the three artists have breathed new life into the ancient art of woodcut. More than just a technique, it’s a dialogue between human touch and natural materials. Each frame holds a deeper narrative of tireless dedication—the careful selection of wood, the precise cuts, the methodical inking, and the final, expectant press. Open to all and continuing until 25 June 2025, Timber Tales will leave visitors with more than just images on paper. In a city rushing to reinvent itself, the exhibition feels like a pause, a reminder of our roots with a sense of belonging—to the artists, to the materials, and to the timeless, meditative act of making. Written By Samira Ahsan

Read More

Royal (Vietnam) selects SACMI technology for a new slab line

The heart of the order is the new Continua+ 2180, equipped with cutting-edge digital decoration solutions Following installation of the new SACMI Continua+ 2180, Royal (Vietnam) becomes the first Asia-Pacific group to equip itself with SACMI technology for on-surface and through-body slab decoration. Moreover, the line is digitally coordinated with Deep Digital solutions, supplied here in an all-round configuration: two DHD digital wet decorators and a DDG digital grit-glue decorator. The new line will allow Royal to expand its range by creating new products with unmatched three-dimensional ‘material’ effects, all the strength and durability of ceramic, and a look that mirrors the aesthetics of natural materials. This important investment decision was not motivated by the innovative forming and decorating technology alone: equally crucial was SACMI’s ability to supply the complete plant, from body preparation (with two spray dryers and relative spray-dried powder conveying/storage systems) to firing in a high-efficiency roller kiln. Already strongly positioned on international markets, Royal has now – with SACMI – taken quality in these high-added-value segments to the next level. For example: the manufacture of ceramic countertops and furnishing accessories, with all the advantages Continua+ has to offer in terms of versatility, productivity and fully flexible control of size and thickness, in coordination with all the digital devices on the line.

Read More

Akij Tableware Art of Plating: Season 2 Crowns the “Plating Maestro”

The curtain has drawn on the remarkable journey of Akij Tableware Art of Plating: Season 2, the pioneering reality show that reimagined tableware as a medium for creative expression and showcased the artistry of modern plating. Following weeks of intense competition, visually striking presentations, and exceptional culinary performances, the grand finale—held on May 16, 2025—served as a fitting conclusion to a season defined by innovation and excellence. Md. Golam Rabby emerged victorious as the champion, taking home the Plating Maestro title along with BDT 10,00,000 along with a professional plating course, national media exposure, and an exclusive Akij Tableware dinner set. The competition was fierce, with equally impressive performances by the runners-up: Iffat Jerin Sarker, awarded Plating Icon (1st Runner-up), received BDT 5,00,000; Dr. Rawzatur Rumman, crowned Plating Maverick (2nd Runner-up), won BDT 3,00,000; Homayun Kabir and Nawsheen Mubasshira Rodela, honored as Plating Masterminds (4th and 5th place respectively), each received BDT 1,00,000. Hosted across Banglavision, RTV, Deepto TV, and streaming on Chorki, Akij Tableware Art of Plating: Season 2 captivated audiences nationwide with its unique blend of tradition and innovation. Contestants turned beloved dishes into visual and gastronomic masterpieces, judged on aesthetics, technique, and culinary understanding. Akij Tableware Art of Plating: Season 2 redefined how we experience food—elevating it from everyday necessity to a dynamic, visual art form. The show celebrated creativity, precision, and innovation, turning each plate into a canvas where flavor met form. Throughout the season, contestants pushed boundaries, transforming ingredients into stunning, story-driven presentations that delighted both the eyes and the palate. More than a competition, this season launched a new movement in culinary expression, inspiring audiences to rethink how food is seen, served, and appreciated. And the journey isn’t over—a new season is coming soon, promising fresh talent, bold ideas, and next-level plating artistry. To stay updated on what’s next, follow www.aop.com.bd and join the evolution of food into a true visual experience.

Read More

SACMI Group 2024: revenues surpass €1.7 billion

The yearly financial statement – approved yesterday, 16th May, during the Parent Company Shareholders’ Meeting – highlighted a net equity of more than one billion euros, growing margins and financial solidity. 2024 also saw the drafting of the first Group Sustainability Plan. Paolo Mongardi, President of SACMI, states: “Sustainability is the fuel of future competitiveness. We continue to invest in people and remain focused on the values that have guided SACMI’s enduring worldwide success” Imola, 17th May 2025 – SACMI closes 2024 with sales revenues of 1.728 billion euros. Despite the complex international economic and geopolitical backdrop, the company’s economic and financial fundamentals proved to be sound. For the first time, net equity exceeded one billion euros (1.055 billion, +172 million compared to 2023) while EBITDA settled at over 323 million euros and EBIT at 236 million. Net profit exceeded 200 million. These were the highlights of the Consolidated Financial Statement, presented yesterday evening, 16th May, at the Parent Company’s (SACMI Imola) Shareholders’ Meeting. “2024 was a solid year that went beyond expectations”, pointed out the President, Paolo Mongardi. “SACMI’s forward-thinking strategy rests on solid foundations and fully embraces the global drivers of digitalization and sustainability”. The year saw a continued focus on the core businesses, confirming the sterling reputation of – and customers’ confidence in – SACMI products across all sectors. In parallel with the to-be-expected slowdown in the ceramic sector – the result of international tensions and the sluggish global construction market – the Rigid Packaging, Advanced Technologies, Packaging & Chocolate sectors all performed excellently, driven by highly dynamic markets receptive to innovation. Investment remained consistently high in 2024 at 71 million euros, in line with the previous year, with a strong focus on innovation (276 new patent applications in 2024 alone, over 6,200 in the Group’s history) and training (over 94,000 hours). In parallel, SACMI confirms its role as a key player in the manufacturing industry’s ecological transition: during the year it presented innovative firing processes (e.g. electric), new process control solutions (thanks also to the acquisition of a majority share in Italvision in 2024), plus new eco-compatible standards, processes and materials in the packaging sector. “Sustainability is the key to future competitiveness”, explains President Paolo Mongardi. “We continue to invest in people by focusing on our values, which have consistently guided SACMI to worldwide success.” The green commitment is also evident at Governance level: the obligations of the new European CSRD (Corporate Sustainability Reporting Directive) were brought forward to 2024 and the first Group Sustainability Plan – an ambitious project that details actions and goals along the entire value chain, from suppliers to local communities – was drawn up. In the ESG sphere, SACMI has strengthened monitoring of indirect emissions linked to the use of its products and plants: this is part of an approach that centers on eco-design and the entire product life cycle to ensure processes are truly circular and impacts are minimized. The share of self-produced renewable energy is also growing (2.6 million kWh), the goal being to progressively decarbonize production facilities. On the employment front, the Group had a total of 4,756 employees at the end of 2024, with over 50% of new hires aged under 30. Close collaboration with universities and research facilities also continued. Ties with local communities – a part of SACMI’s DNA since its founding – became even stronger in 2024, with 90% of procurement networks consisting of local suppliers. Over the three-year period, the company also donated 2.4 million euros to healthcare, educational, safety, inclusion, sports and cultural projects. The year 2024 was a special one for SACMI, with the company reaching the milestone of its 105th anniversary. “We enter 2025 aware of not just the challenges but also the opportunities”, concludes the President, Paolo Mongardi, “with all the confidence that only a long history of innovation, solidity and responsibility can provide”.

Read More

Inauguration of “Selections” at Kishoreganj

AkijBashir Group has recently expanded its footprint with the launch of a new showroom of its brand emporium, Selections, in Kishoreganj. Guided by the motto – “Select from the Best”, Selections was first introduced in October 2022, with the vision of offering customers a one-stop destination for all products under the AkijBashir Group umbrella. Prior to this, six flagship showrooms were inaugurated in key locations across the country—Banani in Dhaka, Agrabad Access Road in Chittagong, Gazi Burhan Uddin Road and Pathantula in Sylhet, Shimultola in Savar, and Keya Hall Road in Tangail. Since its inception, Selections has steadily earned the trust and attention of a wide customer base. To carry forward this momentum, the latest showroom has been launched in Dubail More, near Gaital Bus Stand, Sadar Kishoreganj. The store showcases a wide-ranging collection of ceramic tiles, boards, doors, sanitaryware, bathware, and tableware —bringing all of AkijBashir Group’s renowned brands under one roof. The inauguration ceremony was graced by the presence of Mohammod Khourshed Alam, Chief Operating Officer of AkijBashir Group, who officially inaugurated the showroom by cutting the ribbon. Distinguished guests from the group were also in attendance, including Mohammed Ashraful Haque, General Manager of Sales at Akij Ceramics; Md. Shahriar Zaman, Head of Marketing; Bishwajit Paul, Head of Sales at Rosa; and Md. Hamidur Rahman, proprietor of HS Tiles and Sanitary Gallery. During the event, Mr. Mohammod Khourshed Alam shared, “Our vision with ‘Selections’ has always been to bring the finest AkijBashir Group products under one roof, helping customers elevate their interiors. The Kishoreganj showroom is another step in that direction, offering a wide selection of premium tiles, sanitaryware, faucets, boards, and doors—all curated for discerning buyers”

Read More

Global Spotlight: CERAMICS CHINA 2025 Debuts First 720+ Exhibitors List!

Marking its 39th edition, CERAMICS CHINA—the world’s largest annual event for ceramic equipment and materials—will grandly open in Guangzhou on June 18th-21st Hundreds of exhibitors from over 20 countries and regions will be spread across SEVEN exhibition halls in Area A of the Canton Fair Complex, strategically organized by product categories and business types. Hall 1.1 and Hall 2.1 feature decorative materials, raw and auxiliary materials, refractories, and wear-resistant materials; Hall 3.1 is a concentrated display of foreign pavilions, international enterprises, and well-known brands; Hall 4.1 and Hall 5.1 mainly focus on digital and intelligent technologies, automation equipment, abrasive, tools, and spare parts; Hall 6.1 gathers the most representative equipment enterprises for ceramic tableware and sanitaryware; Hall 8.1 will highlight tile design, innovative processes, and advanced materials. By late April, Halls 1.1-6.1 are fully sold out, and Hall 8.1 is 90% booked with limited space remaining. SECURE YOUR BOOTH NOW! CERAMICS CHINA is not only the exhibition of the largest scale of its kind in the world, but also the most comprehensive in terms of exhibit variety. It offers an all-encompassing range of equipment, materials, accessories, and services—covering the entire production process from raw material processing to finished product packaging and warehousing. One can find advanced equipment, cutting-edge technologies, and innovative solutions tailored to their production needs at CERAMICS CHINA whether it’s for building ceramics, ceramic sanitaryware, ceramic tableware, art ceramics, garden ceramics, or even electrical ceramics, high-tech ceramics, glass, or stone product. As of May 5th, the total number of registered exhibitors has exceeded 720. To facilitate visitors in accessing exhibitor information and planning itineraries in advance, the organizer has decided to release the first batch of exhibitor list to global ceramics industry professionals ahead of schedule. Click to download CERAMICS CHINA 2025 Exhibitor List CERAMICS CHINA attracts industry professionals from across China and around the world annually with its massive scale, numerous exhibitors, diverse exhibits, and exciting events. The previous edition (2024) accommodated 81,858 visits of visitors and buyers from 72 countries and regions. It is projected that this year’s exhibition will draw attendees from over 80 countries and regions, with total participation expected to reach 100,000 visits. June 18-21, Join us in Guangzhou. Don’t miss out!

Read More

RAK Ceramics Unveils Flagship Showroom in Chittagong

RAK Ceramics, the world’s number one multinational tiles brand, has inaugurated a flagship showroom in Kazir Dewri, the heart of Chittagong. With a unique combination of world-class premium tiles, sanitary ware and modern bath solutions, RAK Ceramics is ready to transform customers’ dream homes or modern workplaces. RAK Ceramics’ new showroom is designed to offer a unique experience of sustainable quality, a touch of luxury, and cutting-edge design. Location: H. Tower, 889, Noor Ahmed Road, Kazir Dewri, Chittagong.

Read More

Akij Tableware Art of Plating: Season 2 Premieres on April 25, 2025

Get ready for Akij Tableware Art of Plating: Season 2, premiering April 25, 2025, and turning food into art! Airing weekends on Bangla Vision at 8:15 PM, RTV at 7:10 PM, Deepto Television at 9:30 PM, and streaming on Chorki with new episodes every Friday and Saturday, this vibrant reality show celebrates Bangladesh’s culinary soul. Rooted in Bengali traditions of family and hospitality, contestants transform dishes like fish curries and creamy dal into visual poetry, blending heritage with modern flair. Following its 2022 debut, Season 2 brings high-energy challenges and showcases local talent, from aspiring chefs to home cooks, competing for the “Plating Maestro” title. The grand prize includes BDT 10,00,000, a professional culinary course, national media exposure, and an exclusive Akij Tableware dinner set. With a BDT 20,00,000 prize pool, runners-up and top participants earn cash, certificates, and recognition. Guided by renowned chef Daniel C. Gomez, contestants craft edible masterpieces, judged on aesthetics, technique, and culinary insight after auditions at Hatirjheel Amphitheater. Tune in to Art of Plating: Season 2 to witness a movement redefining dining as a feast for the eyes and soul, where every plate tells a story!

Read More

Akij Ceramics Inaugurates another New Exclusive Showroom at Banglamotor, Dhaka

Akij Ceramics, the leading brand in Bangladesh’s ceramic tile industry, has reinforced its market presence with the grand opening of another exclusive showroom at Banglamotor, Dhaka—a prime hub for the country’s tile market. A six-time consecutive winner of the Best Brand Award and Super Brand Award, Akij Ceramics continues to set industry benchmarks through innovation, superior quality, and an unwavering commitment to its “Promise of Perfection.” Staying true to its customer-centric approach, the brand has inaugurated its newest business associate showroom, “N. Alam Ceramic Centre,” located at 2/1 Poribagh Road, Banglamotor, Dhaka. The inauguration ceremony was held on April 17, 2025 (Thursday), with Mohammad Khourshed Alam, Chief Operating Officer of Akij Bashir Group, presiding as the chief guest. Distinguished attendees included Mohammed Ashraful Haque, General Manager (Sales) of Akij Ceramics; Md. Shahriar Zaman, Head of Marketing, AkijBashir Group; Bishwajit Paul, Head of Sales (ROSA); and Mohammad Noor A Alam Bhuyan, proprietor of N. Alam Ceramic Centre. Designed to offer an unparalleled customer experience, the showroom features cutting-edge product displays showcasing Akij Ceramics’ latest tile designs and size variations. Enhanced with modern furniture and innovative display tools, the spacious outlet ensures a premium in-store experience. With over 130 state-of-the-art showrooms across Bangladesh—both company-owned and business-associated—Akij Ceramics stands as the largest tile manufacturing and distribution brand in the country. The inauguration of the Banglamotor showroom marks another milestone in the brand’s journey to deliver flawless service and excellence to its valued customers.

Read More

‘Kromosho’: Beyond ‘Belonging’

In the middle of the 2000s, a young Munem Wasif started sifting through Old Dhaka’s veins with his aged friend Zenit—a mechanical artifact from the Soviet era. His 2012 photography masterwork “Belonging,” which would revolutionize visual storytelling in Bangladesh’s art scene, was the culmination of a journey that began with this. Similar to the constantly flowing dark waters of Buriganga, which has seen Dhaka undergo changes, Wasif’s own artistic endeavors have veered through several stages throughout time. His work has continuously pushed audiences to look past the obvious, from “Seeds Shall Set Us Free” to “Collapse.” But despite all of these adventures, one thing stayed the same: his strong, unwavering bond with Old Dhaka. Munem Wasif is doing a solo show in Dhaka after nearly 16 years. Titled “Kromosho,” the show is currently ongoing at the capital’s Bengal Shilpalay. Tanzim Wahab served as the exhibition’s curatorial advisor, Iftekhar Hassan as a project assistant, and Dehsar Works as the architectural designer. It is open to everyone and will end on May 31, 2025. “I felt like something was lacking as soon as ‘Belonging’ was released. I felt that I just got the surface of the people and their celebrations; I couldn’t reach the core of their daily existence, the ‘life’ of Puran Dhaka. That’s when I thought of creating “Kheya”l. This exhibition is like a testament to my last two decades of transformation,” remarked Wasif when asked about “Kromosho”. The opening at Bengal Shilpalay was buzzing with energy as art lovers gathered to witness what promises to be one of the most memorable exhibitions in recent times. The exhibition unfolds like a carefully composed symphony in three movements. Starting from Wasif’s ethereal black-and-white photographs from the ‘Belonging’ era, now in dialogue with new color works from ‘Stereo.’ This juxtaposition creates a fascinating tension between past and present, memory and reality. At ‘Kheyal,’ the filmic meditation about what pulses through Old Dhaka’s veins. At ‘Shamanno’ and ‘Paper Negative,’ the installations blend documentation with imagination, challenging our perceptions of what is real and what is remembered. From a critical viewpoint, Old Dhaka represents a ticking time bomb—overcrowded and decaying, it’s an ugly relic of our greed and collective neglect. But Wasif’s work reveals depths hidden in plain sight: the “life” amongst all these. Beyond the obvious chaos lies a world of hidden poetry. This is what ‘Kromosho’ captures so brilliantly—not just images of a place, but its very essence. The exhibition becomes a mirror, asking questions about what we preserve and what we discard in our relentless march toward modernity. In an age of rapid urbanization and cultural amnesia, Wasif’s work serves as both archive and elegy, reminding us of some stories that cannot be captured through cameras or words. To experience its truest essence, you have to be there in flesh and psyche. As visitors move through the gallery, they’re invited not just to see, but perhaps to introspect. In this sense, ‘Kromosho’ transcends being merely an art exhibition; it becomes a conversation, a homecoming, and, most importantly, a call to witness.

Read More

Foshan Uniceramics Expo — Asia’s Largest Industry Showcase Concludes with Resounding Success

2025 Foshan Uniceramics Expo Concludes Successfully, Global Ceramic Industry Gathers for the Event. From April 18 to 22, the 2025 Foshan Uniceramics Expo was successfully held at the Foshan Tanzhou International Convention and Exhibition Center. As the biggest ceramics expo in Asia and a benchmark for the industry, this year’s event brought together over 600 brands from the ceramic, sanitary ware, and equipment & materials sectors, covering the entire industrial chain and showcasing the world’s most cutting-edge new products, designs, technologies, equipment, and materials. For this year’s exhibition, the international participation reaches new heights. 2025 Foshan Uniceramics Expo attracted overseas brands from Italy, Turkey, Japan, Germany, Australia, and other countries, with Indonesian ceramic brands making their debut as a group. The equipment and materials section highlighted its international appeal, featuring continued participation from leading companies in Italy, Germany, Turkey, and other nations, along with new exhibitors from additional countries. Moreover, professional buyers from 85 countries and regions attended, including distributors, traders, engineering firms, and ceramic manufacturers, further solidifying the exhibition’s global influence. Foshan Uniceramics Expo remains committed to its mission of “Bridging world ceramics to China, and China’s ceramics to the world.” Moving forward, it will continue to foster deeper exchanges and cooperation in the global ceramics industry, injecting new vitality into its international development. Stay tuned for the next edition!

Read More

In Search of the Mangrove Goddess

Exploring the Sundarbans’ cryptic mangroves may be a weird, larger-than-life experience. When danger occurs in this wide wilderness, instinct frequently prompts one to seek spiritual protection. In such cases, the Sundarbans’ guardian spirit—Bon Bibi or Bono Bibi—is invoked. Bon Bibi is revered by the local forest dwellers as the divine guardian of the region’s treacherous environment. From April 4 to April 20, the Kalakendra gallery at the capital’s Lalmatia featured “In Quest of Bono-Bibi,” a mixed-media solo exhibition by artist Saidul Haque Juise. Juise, known for his precise craftsmanship, bright masks, and three-dimensional compositions, returned with a solo display following a long absence. Bon Bibi’s mythology is unique in that it combines both the Islamic and Hindu traditions, and it is commonly held that invoking her name in times of crisis promises divine assistance. The stories related to Bon Bibi are woven in a rich tapestry of mythology, which prodded Juise’s psyche when he was a child. Later in life, deeply touched by the Sundarbans’ environmental deterioration, he created this body of work as a lament and devotion to nature. This anthology, with its recurring themes of environmental concern and political overtones, combines lyrical extracts from folklore or shloks related to Bon Bibi with his own storytelling. The birth of these artworks dates back to the COVID pandemic. A time when despair loomed large. It was during this emotional upheaval that the artist Juise channeled his sorrow, frustration, and fear into a series of expressive sketches. Using vibrant shades of black, green, red, and blue— which are reminiscent of traditional Bangladeshi folk pottery— Juise stained his pages with raw emotion. Later, by combining various materials, such as twisted metal wires, paint, ink, handmade paper, newspaper pieces, etc., Juise enhanced the series even further. He was able to convey Bon Bibi’s holy force and the forest’s ethereal essence through these components. His line drawings smoothly blend with his pen and ink pieces to create complex collages that have a vibrant yet delicate vibe. In the meanwhile, the collection gains a tactile, even unearthly quality from his wire sculptures. The series gives viewers a deep feeling of Bon Bibi’s pervasive atmosphere. Along with his technical finesse, Juise added a unique Bengali flavor to the pieces. He skillfully combined the forms of people, animals, and insects to create flowing silhouettes that convey both motion and motionlessness. These shapes convey a duality: sadness that is subdued yet evident and fury that is controlled but strong. In doing so, Juise creates a collection of work that is both visually pleasing and profoundly significant by balancing artistic form with emotional weight. “In Quest of Bono-Bibi” stands much like an artistic diary that procures the artist’s personal reflections, cultural memory, and the urgent call for ecological reverence. It bridges folklore and modernity, spirituality and artistry—ultimately offering a visual testament of healing and harmony between humans and the natural world.

Read More

Institute of Architects Bangladesh Brings Pohela Boishakh to Life on Its Premises

The Institute of Architects Bangladesh (IAB) welcomed the Bengali New Year in vibrant style, hosting its first-ever Pohela Boishakh celebration on its premises. Titled “Esho Mati Notuner Ahobane”, the event was a colourful and cultural affair that reached beyond the architectural fraternity. Architects’ spouses, children, and extended family were warmly welcomed. The idea was simple: to celebrate the new year and the people who stand behind the scenes of every great architect. Festivities began at 3 PM, as the rhythmic beat of traditional dhol set the tone. Architect Asif M Ahsanul Haq, Convener of the Bengali New Year Celebration Committee, opened the event, inviting everyone into the heart of the celebration. With warm smiles and colorful attire, attendees embraced the spirit of community and enjoyed the laughter and tradition with their extended family. The IAB grounds were transformed into a festive fair, with interactive cultural corners drawing crowds throughout the day. Children gathered around clay artists and potters, their hands deep in clay, learning to mold traditional shapes. Nearby, shitol pati (cooling mat) weavers demonstrated their age-old techniques, encouraging young participants to try their hand at weaving. A painting zone was also set up, where children were free to create without the pressure of competition. Their artwork was later displayed, showcasing unfiltered creativity and color. Laughter echoed from the crowd gathered around the Putul Nach (puppet dance) and magic show, where entertainment delighted audiences of all ages and reminded everyone of the charm of folk performances. At the heart of the event was a bustling Meena Bazaar, alive with the flavors of tradition. Stalls served familiar favorites—muri, murki, naru, moya, samosa, beguni, lemonade, and kacha aam er shorbot—while architects and their families showcased their creative talents through stalls featuring homemade food, traditional sarees, books, paintings, and handmade crafts. It was a beautiful blend of personal passion and cultural pride. Major industry sponsors, including Berger Paints Bangladesh, Italiano Marble and Granite, Indigo Marble and Granite, Tilottoma Group, and Space Couture, added their own festive touch. Their vibrant booths offered free face art, portrait sketches, and a variety of Bengali snacks and refreshments, contributing to the lively spirit of the day. As the sun began to set, the stage came alive with folk songs and traditional dances performed by members of the architectural community. The soulful performance by Sadhu Songo, a renowned Lalon music troupe, captivated the audience with its spiritual melodies. The evening came to a heartfelt close with a collective rendition of “Esho He Boishakh,” followed by heartfelt closing remarks from Professor Dr. Abu Sayeed M Ahmed, President, and Professor Dr. Masudur Rashid, General Secretary of the Institute of Architects Bangladesh. The night concluded with a warm, memorable dinner under the open sky—an evening to remember. This landmark celebration was not just about welcoming a new year, it was about embracing shared roots, honouring cultural expression, and celebrating the bonds that make up the architectural community.

Read More

Celebrating Hamiduzzaman Khan

From 31 January to 15 March, the first-floor gallery of the capital’s Bengal Shilpalay transformed into a mesmerizing display of incredible sculptures and paintings. Titled “Hamiduzzaman Khan,” the spectacular exhibition organized by Bengal Arts Programme honored the life and works of Hamiduzzaman Khan, one of Bangladesh’s most distinguished sculptors. The inauguration took place on Jan 31, graced by the presence of artist and art writer Mustafa Zaman; the director general of Bengal Foundation, Luva Nahid Choudhury; prominent Bangladeshi-Spanish artist Monirul Islam; and architect Mustapha Khalid Palash. Neatly curated by the esteemed Mustafa Zaman, the exhibition was a visual diary of Hamiduzzaman’s lifelong dedication to modern experimental art, which provided visitors with a profound insight into his artistic journey. Some pieces were delicate and intricate, while others were monumental and commanding. His use of geometric abstraction and semi-abstract forms is a testament to his imagination and craftsmanship. The artist has spent decades exploring new artistic dimensions. His ability to transform objects into unique sculptural forms has captivated art lovers even beyond borders for decades. The exhibition at Bengal Shilpalay featured quite a big collection of his artworks, showcasing his talent across multiple mediums including metal and stone sculptures, watercolor paintings, and acrylic paintings inspired by his sculptures. It also showcased some of his sketches, exhibition catalogues, and books on his art. The curator, Mustafa Zaman, praised the artist’s innovative approach to form and structure. He remarked, “Hamiduzzaman sir has consistently delved into the essence of objects, transforming and redefining their shapes in extraordinary ways. His creations showcase decades of dedication and artistic exploration, reflecting a deep commitment to pushing boundaries and reimagining possibilities.” Zaman highlighted the artist’s ability to blend tradition with experimentation, resulting in works that are both timeless and groundbreaking. Hamiduzzaman’s art, he noted, stands as a testament to his relentless pursuit of reinterpreting the familiar into something profoundly unique and thought-provoking. Prominent architect Mustapha Khalid Palash, a guest at the inauguration, shared his admiration, saying, “His simple yet deeply impactful works remain a source of inspiration. This exhibition beautifully celebrates his artistic legacy, offering younger generations a chance to reflect on and reconnect with their cultural roots. It’s a tribute to his enduring influence and a reminder of the power of art to bridge the past and present.” Born in Kishoreganj in 1946, Hamiduzzaman Khan studied at Dhaka Art College (now the Faculty of Fine Arts, Dhaka University) and was mentored by legendary artists like Zainul Abedin, Abdur Razzaque, and Mustafa Monwar. He transitioned from painting to sculpture, pioneering sculpture parks in Bangladesh and leaving behind an impressive legacy. Some of his most popular sculptures include “Shangshaptak” at Jahangirnagar University, “Flying Bird” at the World Bank Dhaka office, “Jagrotobangla” in Brahmanbaria, “Freedom” at Krishibid Institute, and “Peace Bird” at TSC. Expressing his gratitude, Hamiduzzaman Khan spoke about his journey as an artist. “Creating modern experimental artworks in various mediums has been my passion for many years. It hasn’t always been easy, but I am grateful for the support of my peers and art lovers.” The great artistic mind further added, “I am almost 80 years old, but I want to continue making art as long as my mind and body permit!’

Read More

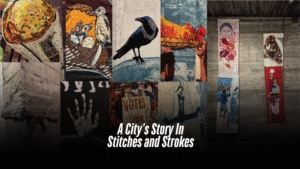

A City’s Story in Stitches and Strokes

Dhaka’s rapid urbanization is impossible to ignore. This city of relentless energy and transformation is a place where tradition and modernity collide amidst its bustling streets and ever-changing skyline. As the economic heart of Bangladesh, it draws thousands seeking better opportunities. But this comes at a cost: overcrowding, strained resources, and a growing disconnect between the old and the new. Against this backdrop, ShohorNama Dhaka Episode II sought to explore the city’s complexities through art. Launched in early 2024, the project brought together visual artists, architects, artisans, and students from the University of Dhaka’s Faculty of Fine Art to create a tapestry of urban narratives. And the exhibition of this project took place from February 15 to 25 at the level 4 under construction space of the capital’s Bengal Shilpalay. The exhibition was inaugurated by H.E. Marie Masdupuy, Ambassador of France to Bangladesh, on February 15, 2025. Titled after the project name, the multidisciplinary exhibition wove together the threads of urban life, resilience, and creativity. Presented by the Bengal Arts Programme in collaboration with the Britto Arts Trust, ShohorNama II was a visual love letter to Dhaka, its people, and their stories. From large appliqué tents to wood-cut prints, installations, and performance art, it was a celebration of Dhaka’s artistic topography. At its core, ShohorNama was about storytelling. One of the standout features is the Pakghor Project, a community kitchen born out of necessity during the devastating floods of 2024 in the Khulna region. Pakghor provided warm meals to 500 villagers for a week. But it became more than just a kitchen—it became a space for shared stories, resilience, and hope. The Dorjikhana Project takes a different approach, focusing on textiles and their cultural significance. Through appliqué and embroidery, artists explore the connection between traditional practices and the modern garment industry. The project also draws inspiration from Bangladesh’s fading circus traditions. Resulting in a stunning collection of textile art that speaks to both the past and the present. Another striking element of ShohorNama is its use of tents. Historically, tents have symbolized temporary shelter for nomadic communities, and in this exhibition, they represent the fluidity of migration—whether due to natural disasters, economic hardship, or political unrest. The Big Tent installation captured this impermanence, reflecting the challenges faced by marginalized communities. The exhibition also highlighted the collaborative spirit of the project. Workshops with the University of Dhaka’s Department of Printmaking and Department of Craft allowed students to contribute to large-scale works, such as woodcut prints and appliqué pieces. These workshops not only honed technical skills but also fostered a sense of shared purpose, blending individual creativity into a cohesive vision. The exhibition was a feast for the senses! As Dhaka continues to evolve, exhibitions like “ShohorNama Dhaka Episode II” remind us of the importance of preserving our stories and traditions. Through art, we can find common ground, build resilience, and imagine a better future.

Read More

Where Artist and Audience Intertwined

Amidst the quietness of Lalmatia’s Block F lies Shunno Art Space—like multidisciplinary artists, it’s also multidisciplinary in character. Limited in floor area but with an illimitable heart, the space adorns exhibitions, has a printing workshop set up, and has a café—intertwined. From February 15 to 22, this cozy space hosted artist Sanjid Mahmud’s solo exhibition “Tracing The Distance.” The week-long exhibition witnessed a vibrant crowd, and the inauguration was graced by eminent artistic figures Hamiduzzaman Khan and Mustafa Zaman. “Exhibition visitors observe art passively, only admiring the finished works. They only view; they don’t paint. But here, they were active participants. They picked up brushes and poured their emotions into the canvasses. Even those who don’t know how to draw found themselves painting. Their raw, unfiltered expressions became the foundation. Then, I stepped in, adding my artistic intervention, blending their spontaneity with my vision.” These words from the artist Sanjid himself perfectly procure the zeitgeist of “Tracing the Distance.” Sanjid Mahmud’s “Tracing the Distance” was an artistic co-production between the artist and the exhibition visitors that prioritized real-time cooperation and process over finality. Art, being a collaborative enterprise, carries remnants of prior forms by combining individual expression with common experiences. However, Sanjid Mahmud’s initiative changed the attention away from linguistic borrowing and toward overlapping artistic expressions in the moment, resulting in a dynamic interplay between creator and participant. Visitors at Shunno Art Space were greeted with empty canvases and encouraged to add spontaneously. The act of production was valued over passive viewing, encouraging people to leave their mark on the canvasses however they liked, be it sketchy motions or painterly strokes, regardless of their creative ability. This fun and engaging method relieved the pressure of normative practices, allowing for raw, unfiltered expression. Sanjid Mahmud then stepped in, responding to these inputs without striving for a certain style result. The end result was a body of work that defied decisive conclusion, undermining modernist conceptions of linear progression and chronological time. The title of the exhibition, “Tracing the Distance,” emphasized its purposeful break with the logic of modernity, which minimizes artists’ territorial consciousness and frequently limits them to historical circumstances. Through the process of collaborating with his audiences, Sanjid Mahmud challenged the conventional understanding of art as a “significant form” or a refined praxis. In order to reveal the fluid, communal character of creativity, he instead opened the gallery’s “white cube.” By means of this collaborative approach, the artist stimulated a reconsideration of the connections among art, artists, and the art community. Thus, Shunno Art Space transformed into a place of reflection where both appreciation and creation are rethought. By emphasizing the act of doing rather than observing, “Tracing the Distance” questioned established hierarchies and honored the beauty of group, unplanned expression while providing a novel viewpoint on the ever-changing conversation between shared and individual artistic languages. Written By Shahbaz Nahian

Read More

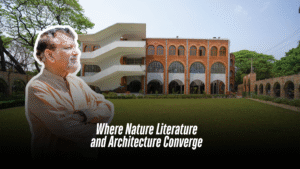

Aarong Flagship Store A Symphony of Architecture, Design and Craft

Aarong, the flagship brand of BRAC, has long been a beacon of Bangladeshi craft and heritage. Since its founding in 1978, it has evolved from a humble platform supporting rural artisans into one of the most iconic lifestyle retailers in the country. At every stage of its journey, Aarong has remained dedicated to preserving traditional crafts while embracing innovation in design and retail. This commitment culminates in its latest and most ambitious endeavor: the Aarong Flagship Store in Dhanmondi. This isn’t just a new store; it’s a monumental celebration of Bangladeshi craftsmanship, culture, and creativity. With its grand opening, the Aarong Flagship Store has become the world’s largest craft store. Yet beyond the scale, it is the thoughtfulness of the design, the intricacy of the artistry, and the profound connection to Bangladesh’s heritage that make it truly remarkable. Here, architecture becomes a canvas, interiors breathe with narrative, and every art installation stands as a tribute to the nation’s soul. Weaving a Legacy in Concrete At the heart of Dhanmondi, where tradition meets the rhythm of urban life, stands a building that does more than offer products—it tells a story. The Aarong Flagship Outlet, designed by the visionary team at Synthesis Architects, is not merely a retail space—it is a woven fabric of heritage, memory, and movement. The design draws its soul from an age-old practice: weaving. For generations, Bangladeshi artisans have mastered the loom, interlacing threads into forms that embody both beauty and utility. This fundamental craft became the architectural metaphor—fluid, connected, and timeless. A singular, sweeping ribbon—symbolic of woven fabric—emerges from the ground, bends, flows, and re-emerges, wrapping the building in a gesture that is both gentle and bold. This ribbon, meticulously cast in handcrafted concrete, intertwines tradition with contemporary expression. It shields and shelters, filters light and air, and gracefully performs the roles of both skin and soul. Designing for Aarong, a brand synonymous with preserving and promoting Bangladeshi craftsmanship, was an exercise in alignment. It was about giving architectural form to a cultural mission. The interior was choreographed as an experience. Color, texture, and flow were orchestrated to tell stories of rural hands, tribal patterns, and generational skill. The internal movement—voids, escalators, panoramic lifts—echoes the interlacing of threads on a loom. The building doesn’t simply house craft; it embodies it. There were challenges—limited plot size, urban code restrictions, and the complex layering of customer experience. But like the imperfections in a handwoven textile, these constraints added to the character. The architects embraced a rare construction process involving custom shuttering techniques that fused handcrafted care with structural innovation. It was, in many ways, architecture as craft—thoughtful, tactile, and deeply human. The Aarong Flagship Outlet is more than a commercial destination—it is a living artifact. A building where the spirit of Bangladesh rises through poured concrete, where ribbons of history and modernity interlace, and where the vision of Synthesis Architects comes alive in every curve, corner, and corridor. Narratives in Space: Designing Aarong’s Interior Stepping inside Aarong’s Dhanmondi flagship store is like entering a carefully curated journey through the textures, colors, and stories of Bangladesh. The interior design—an inspired collaboration between DWm4 Intrends Ltd, KNMR Ltd – Quirk & Associates JV, and Aarong’s in-house team—transforms the space into something far more than a retail outlet. It becomes a living, breathing storybook. From the outset, Aarong’s internal creative team played a vital role in shaping the vision. With deep roots in the brand’s philosophy and a nuanced understanding of its audience, they ensured the design remained authentically rooted in Bangladeshi heritage while pushing the boundaries of modern retail aesthetics. Guided by a philosophy rooted in transparency, movement, and nature, the space invites exploration. A rich interplay of materials, tones, and layers creates a rhythmic flow throughout the store. The tactile warmth of crafted surfaces, the strategic use of natural light, and the organic integration of greenery collectively form an ambiance that is both calming and dynamic. Each area reveals a distinct narrative, woven through thoughtful transitions that guide visitors from one crafted world to another. Every detail reflects a broader intention: to connect the threads of past and present, tradition and innovation, artisans and their audience. The space becomes part of the product’s story, amplifying its meaning and value. Executed with precision and artistry by the expert team at Charuta Limited, the interior fit-out brings this collective vision to life. At the heart of this journey was the dedicated team of architects and designers from Aarong, whose cultural insight and creative vision shaped an environment that celebrates both legacy and innovation . Art Installations: Where Stories and Spaces Intertwine Beyond architecture and interiors, the Aarong Flagship Store stands out for its large-scale art installations—transforming it from a retail space into a cultural landmark. Each piece, created by a blend of independent artists and Aarong’s in-house team, captures a different facet of Bangladeshi life and heritage. The Great Arena: A Monumental Nakshi Kantha Designed by Samiul Alam Himel in collaboration with Aarong’s in-house team, this towering four-story installation reimagines the storytelling tradition of Nakshi Kantha in architectural form. Traditionally stitched by rural women to document everyday life, these narrative quilts are here translated into flowing sculptural lines and vivid, layered colors. Titled “MohaArongo: The Great Arena,” the piece stretches 44 feet high and 10 feet wide, handcrafted over six months by 250 artisans from rural Bangladesh. The work is not only monumental in scale but also in meaning. Created from repurposed fabrics, salvaged beads, and discarded ornaments, it embodies a philosophy of renewal and resilience. The piece weaves a narrative journey through rural life, folklore, urban aspirations, and cosmic imagination—stitched in intricate Nakshi Kantha techniques drawn from Aarong’s archives and reinterpreted across various fabrics. Orange threads guide the eye through this swirling story, culminating in motifs like peacocks, trees of life, and village fairs, each carrying hidden stories within their forms. Rising through the central atrium, the installation invites viewers to look upward and

Read More

PEOPLES CERAMIC INDUSTRIES Clay, Fire, Art: A Story of Dreams

As the morning sun gently illuminates glass windows and casts playful shadows on the floor, a new day’s story unfolds. Beyond the city’s hustle and bustle, skilled hands at Peoples Ceramic Industries Limited (PCI) work tirelessly to craft each perfect piece—an extraordinary fusion of clay, fire, and creativity. Today, Bangladesh’s ceramic industry has evolved far beyond home décor into a globally recognised brand. At the forefront of this transformation is PCI. Established in 1962—originally known and registered as Pakistan Ceramic Industries Ltd.—the company has grown over 63 years into one of the nation’s oldest and most respected ceramic manufacturers. Its reputation for high-quality porcelain tableware, sustainable technology, and a robust international presence speaks for itself. In this edition of Ceramic Bangladesh, we sat down with Lutfur Rahman, the Managing Director of Peoples Ceramic Industries Ltd. A visionary in his own right, Lutfur has both preserved and expanded his father’s legacy, positioning PCI as a key player in Bangladesh’s industrial evolution. A Legacy Built on Vision and Integrity Lutfur Rahman began the interview by proudly showing a photograph of his father, Ansar Uddin Ahmed—the mastermind behind Peoples Ceramic. A civil engineer who graduated from Ahsanullah Engineering College (now BUET) in 1947, Ansar Uddin was driven by an enduring desire to serve his country—not through bureaucracy but by creating something truly meaningful. After a brief stint in the government sector, he pursued his entrepreneurial dreams. In the early 1950s, he founded United Engineers, securing a first-class license from the government. His firm was responsible for several prominent constructions that still stand today, including the Ceramic Institute in Tejgaon, Dhaka Polytechnic Institute, and Chittagong Medical College and Hospital. It was during his frequent visits to the Ceramic Institute that the idea for a ceramic factory was born. Reflecting on his father’s journey, Lutfur shared, “The relationship between children and their parents has always been special. I grew up watching my father work relentlessly, with my mother by his side supporting every step. His singular desire was to create a new industry and leave behind porcelain tableware as a legacy to improve the quality of life for our people. To realize this dream, he embarked on a long, challenging journey filled with obstacles. He always said, ‘To achieve something, one has to give up something, and there is no shortcut to building a solid foundation.’” The Birth of Peoples Ceramic In 1962, Peoples Ceramic Industries Ltd. was established with a clear and powerful vision—to provide affordable porcelain tableware for ordinary people. At a time when ceramic products were considered a luxury, Mr. Ahmed aimed to bring dignity and elegance to everyday dining. The company chose to manufacture European-style tableware, targeting both local tastes and future export opportunities. By 1982, PCI had successfully entered the international market, with its porcelain products welcomed in Holland and the United Kingdom. Located in the Tongi Industrial Area—a prominent industrial zone in Gazipur, just 20 kilometers from Dhaka—PCI started with basic housewares, tea cups, and saucers designed primarily for restaurant use. Over time, the product line expanded to include institutional ranges catering to hotels, restaurants, and the broader hospitality sector. Reflecting on the company’s humble beginnings, Lutfur recalled, “Peoples Ceramic was established in 1962, with the technical support of Sone Ceramic, Japan. At that time, Japanese engineers stayed in Dhaka to supervise the installation and production process. In the early days, our factory ran on furnace oil, and our products gained popularity right from the start.” Mr. Ansar Uddin Ahmed, who served as managing director of both Peoples Ceramic Industries and Standard Ceramic Industries Ltd., passed away on August 17, 2005. He also served as the first President of the BCMEA from 1992 to 2002, playing a vital role in revolutionising the export of local ceramics. “Tajma Ceramics, established in 1959, was the pioneer in manufacturing earthenware. However, PCI was the first to introduce porcelain production in Bangladesh,” Lutfur explained. According to him, PCI was formally inaugurated by then Industries Minister Dewan Basit and the Japanese Ambassador, with commercial production beginning on June 23, 1966. Overcoming Challenges and Embracing Innovation Marketing large-scale production in the early years posed a significant challenge. To overcome this, Mr. Ahmed ventured into the Pakistani market, successfully competing against two established factories. PCI’s hard-grade porcelain quickly won acceptance, carving out its niche within the subcontinental market. The company has consistently invested in state-of-the-art technology, global raw material sourcing, and upgraded machinery to guarantee quality and cost-effectiveness. This forward-thinking approach has enabled PCI to stay ahead of industry trends for decades. In 2009, the company introduced decal printing—initially using basic logos—and by 2012 had established a fully automated decal printing facility, expanding its design capabilities and reinforcing its brand identity. Aesthetic Diversity: Designs That Tell a Story Today, PCI offers a diverse range of tableware, neatly categorized into housewares, hotelware, and giftware. The company produces approximately 13 million pieces of porcelain tableware annually and employs nearly 712 people. These milestones stand as a tribute to its commitment to quality and innovation. The Road Ahead: Legacy and Vision Under Lutfur Rahman’s leadership, PCI continues to honor his father’s legacy with dedication and innovation. The company has adopted sustainable production practices and is actively exploring new export markets. As Lutfur puts it, “We still hold on to the principles my father set—quality, integrity, and making ceramics accessible for all. Our goal is not only to serve our customers but also to contribute to the country’s economic and industrial growth.” Looking to the future, PCI is exploring renewable energy integration, digital production processes, and expanding its footprint into emerging markets in Asia and Africa. As Bangladesh’s ceramic industry gains global prestige, Peoples Ceramic Industries Ltd. remains at its heart—a symbol of dreams forged in clay and fire, shaped by vision, and driven by a commitment to excellence. Maximizing Waste Utilization in Ceramic Production PCI is also a leader in sustainable practices. “We actively reclaim ceramic scraps at various stages of production—including the green (unfired), bisque

Read More

Celebrating 5 Years of Success of the Sponsors and Patrons Recognition

Shaping Bangladesh was one of the most prestigious events of Ceramic Bangladesh Magazine, organized by BCMEA (Bangladesh Ceramic Manufacturers and Exporters Association). The event gathered many renowned and well-known architects, engineers, industry leaders, and industry personnel from different sectors under one roof. It was a different way of introducing the new ways of rebuilding and reshaping Bangladesh with many unique and extraordinary ideas and thinking of brilliant minds and visionary individuals of the country. Without the support of the sponsors, the event would never have happened in reality. It was the encouragement, support, and dedication of the valuable sponsors who have come forward to make this event successful and create a new buzz in the town. On that note, special thanks to all the sponsors and partners of the event for making a special and notable contribution to the event and playing their part crucially. Valued Sponsors of Shaping Bangladesh Special recognition and deepest gratitude to the valued sponsors and partners for providing their invaluable support. Their generous contribution has played a significant role in making this event possible and helping BCMEA bring all the valuable communities together to promote a meaningful experience. The valued sponsors of Shaping Bangladesh were: • Platinum Sponsor: Akij Ceramics Limited • Powered by Sponsors: Meghna Ceramic Industries Limited. and X Ceramics Limited • Associated Sponsors: Sheltech Ceramics Limited, DBL Ceramics Limited, Mir Ceramic Limited Event Partners: • Gift Partner: RAK Ceramics (BD,) Ltd. • Media Partner: The Business Standard • Hospitality Partner: Dhaka Regency and Chuti Resort • Wardrobe Partner: Fiero • Other Supporting Partners: 01. BHL Ceramic Co. Ltd., 02. Mirpur Ceramic Works Ltd., 03. Ali Ceramic Ind. Ltd., 04. Adroit Swimming Ltd., 05. Nupami BD Ltd., 06. Amber Board Mills Ltd., 07. Lonon BD BCMEA and Ceramic Bangladesh Magazine are extremely grateful and honored by their presence and collaboration for the event, and they also look forward to continuing these valuable relationships in the future by working together. Top 5 Contributors in 5 years journey of Ceramic Bangladesh Magazine Shaping Bangladesh was not only an event to gather the brilliant minds, but it was also a remarkable celebration for the 5-year successful journey of Ceramic Bangladesh Magazine. BCMEA and Ceramic Bangladesh Magazine expressed their heartfelt gratitude to the constant supporters of the publication. Here are the top 5 contributors of the Ceramic Bangladesh Magazine in last 5 years who have helped to sustain the publication and allowed the magazine to grow, evolve, and continue delivering quality content to the readers, and showcase unique and extraordinary stories through the lenses of writers and photographers. Moreover, the continuous and unwavering belief in the publication was the cornerstone of this event’s success. The partnership has made the event more meaningful. BCMEA and Ceramic Bangladesh Magazine are truly honored to have all the sponsors, partners, and contributors by their side and look forward to continuing this journey together by building more impactful and significant years ahead.

Read More

Kromosho Beyond ‘Belonging’