Author: admin

Akij Ceramics Introduces 100×100 cm Large Tiles

In response to the growing global demand for large-format tiles, Akij Ceramics proudly introduces its new Kathena premium series, featuring 100×100 cm (1000×1000 mm) tiles. These grand tiles, designed to deliver a seamless and luxurious aesthetic in both residential and commercial spaces. Previously, consumers had to rely on costly imports with limited design choices. Now, Akij Ceramics brings a solution that not only meets but exceeds international standards in design, durability, and performance. Produced locally, these tiles provide an affordable and superior option, enhancing the landscape of the Bangladeshi tile industry. Akij Ceramics’ 100×100 cm tiles, known for their high gloss finish, add an unparalleled sense of space and elegance to interiors. With fewer grout lines, these tiles deliver a clean, expansive look that perfectly complements modern design trends. The diverse range of designs ensures that there’s something for every style preference, making them ideal for both residential and commercial application By launching these large-format tiles, Akij Ceramics continues to set new industry benchmarks, reinforcing its reputation for innovation, quality, and craftsmanship. Their “Promise of Perfection” shines through in every product, solidifying their status as one of Bangladesh’s top ceramic brands. Whether you’re transforming your home or commercial space, Akij Ceramics’ new 100×100 cm tiles offer the ultimate combination of beauty, performance, and luxury.

Read More

AkijBashir Group and Edison Real Estate Forge Strategic Partnership to Enhance Customer Experience

AkijBashir Group and Edison Real Estate Limited, have formed a strategic partnership to

enhance customer value and offer exclusive benefits. This collaboration will provide exclusive

perks to members of the Edison Royal Club, a loyalty program designed for Edison Real

Estate's esteemed clients.

Cartoon e Bidroho’- A bloodshot rebellion portrayed in art!!

Cartoon e Bidroho’- A bloodshot rebellion portrayed in art!!

Read More

A palace on the bank of Buriganga

An integral part of Dhaka’s image in terms of historical architecture that still remains and has been renovated and preserved is the Ahsan Manzil. And like many of common folks who grew up in Dhaka, they have always wondered, at least once in their lives, the reasons behind why this iconic landmark is painted pink. Perhaps unsurprisingly, Ahsan Manzil’s history is even more colourful. This iconic building was built on a property that has a rich history dating back to the Mughal era at the southern part of Dhaka. During the Mughal Empire, Sheikh Enayet Ullah, Zamindar of the Jalalpur Porgona (Faridpur-Barishal), who was the original owner of the land, built a palace called Rong Mahal (which loosely translates as ‘Colourful Palace’) in 1720 for his amusement, a typical practice amongst wealthy elites at the time. He also had a garden house and a cemetery on this site. After he passed away, his son Sheikh Moti Ullah sold the property to the French traders in Bengal at the time. The new owners soon established a trading house next to the palace. Later, after being defeated in the Palashy War by the British East India Company in 1757, they had to leave their possessions behind. After changing hands a number of times, the property was purchased by Khwaja Alimullah of Begambazar in 1830, who was a prominent merchant and an important figure of Dhaka’s Muslim community at the time. Alimullah renovated the property, turning the trading house into a residence. He also built a mosque and some other important structures in this area. After his death in 1854, his son Khwaja Abdul Ghani inherited the property and named it Ahsan Manzil after his son Khwaja Ahsanullah. He continued renovations; the old building was renamed Ondor Mohol (ladies quarters) and the new building was called Rangmahal (pleasure palace) and was later renamed Ahsan Manzil. Khwaja Abdul Ghani was one of the most influential Nawabs (Zamindar) of Dhaka. Known for his generosity and patronage of arts and culture, he expanded his estate by acquiring more lands around Ahsan Manzil and also played an important role in improving the infrastructure, education, healthcare, trade, and social welfare of Dhaka. In 1859, he built a new building on Ahsan Manzil’s property that resembled European architecture because of its domes and pillars. The Nawab named it Rangmahal and painted it with different colours every year according to his mood. On 7 April 1888, Ahsan Manzil suffered severe damage from a tornado that impacted most of its buildings, except for Rangmahal and it was temporarily abandoned. Khwaja Abdul Ghani then decided to rebuild Ahsan Manzil with more vigour and decorations than previous ones. He hired Martin & Co., a British construction and engineering f irm, who designed Ahsan Manzil with an Indo-Saracenic style, blended with Islamic and European elements. In 1872, the reconstruction work continued under Khwaja Abdul Ghani’s supervision, what was previously the French trading house was rebuilt as a two-storey building similar to the Rangmahal. A wooden bridge connected the first floors of the two buildings. After he died in 1896 at the age of 87 years, his son Khwaja Ahsanullah continued his father’s legacy by taking care of the palace. He added new features like electric lights, gas lamps, and water pumps as part of modernization. The palace was repaired again following the 1897 Assam earthquake. The Nawab family played crucial roles in the modernisation of the Dhaka city, particularly in the development of educational systems, healthcare, and urban infrastructure, including the f iltered water supply system that served the city population. They occupied important positions as Commissioner of Dhaka Municipality. Today, within the hyper-congested and cacophonous urban growth of Old Dhaka, it is difficult to imagine how this majestic edifice once dominated the riverfront skyline of Dhaka. The landmark is a unique fusion of architectural styles, reflecting the rich cultural influences that shaped Bengal it over the centuries. The main palace building showcases a harmonious blend of Mughal and European architectural styles. The Mughal influence is evident in the structure’s domes, arches, and intricate decorative motifs. The ornate design of the palace’s entrance and interior chambers reflects the opulence that was characteristic of the Mughal era. European influences, on the other hand, are seen in the high ceilings, broad staircases, and expansive verandas. The palace’s central ballroom, adorned with crystal chandeliers and European-style furniture and tableware, exudes an air of sophistication that was imported from Europe during the late 19th century. The building faces the Buriganga River and Buckland Dam. On the riverside is a stairway leading up to the 1st floor. A fountain previously sat at the foot of the stairs but was not rebuilt. Along the north and south sides of the building are verandas with open terraces. Ahsan Manzil is ostentatiously European in its architectural expression, even though the building’s recessed verandahs may recall the Mughal treatment of buildings in a tropical climate. Its triple-arched portal, Greco-Roman column capitals, pilasters, and arched windows—all suggest that it is mostly a European-style building, meshed with some decorative Indian motifs. The palace’s soaring dome appears to be more about impressing the viewer on the exterior, rather than within the interior. The dome is at the centre of the palace and is complex in its design. The room at its base is square with brickwork placed around the corners to make it circular. Squinches were added to the roof corners to give the room an octagonal shape and slant gradually to give the dome the appearance of a lotus bud. The dome’s peak is 27.13 metres (89.0 ft) tall. The palace is divided into the eastern side, the Rangmahal, and the western side, the Andarmahal. The Rangmahal features the dome, a drawing room, a card room, a library, a state room, and two guest rooms. The Andarmahal has a ballroom, a storeroom, an assembly room, a chest room, a dining hall, a music room, and a few residential rooms. Both the drawing room and

Read More

An Ode to Resilience: Shaheed Minar’s Chronicle of Revival

In the Bengali calendar, the month of Falgun signifies new journey of life and a sense of rejuvenation. The month which marks beginning of the spring brings forth joy, vivid hues, and a feeling of renewal. During this time, Bangladesh comes to life with the mesmerizing songs of cuckoos and various f lowers that are in bloom. Urban streets and rural roads are painted with colours of fallen leaves and shades of flowers. However, on the eighth day of Falgun, February 21, 1952, the Dhaka city’s streets were transformed into haunting canvases as the vibrant hues of nature gave way to a chilling shade of dark red. In defiance of the curfew imposed, courageous students took to the streets, passionately demanding that Bangla and only Bangla be recognised as the nation’s state language. The police opened fire on the students. Salam, Barkat, Rafiq, Jabbar, and a few others tragically lost their lives in the incident. Many people were injured. The news of the shooting spread like wildfire in every corner of the city. Soon after, the office court, secretariat, and wireless centre employees decided to collectively refrain from attending work. A wave of frustration swept through the city, drawing people towards the Dhaka medical hostel premises. After a day of fervent protests and demonstrations, the leaders of the student community agreed as a group to honour the language martyrs by constructing a monument. The information quickly got to Badrul Alam, a 24-year-old artist who is well-known for his artistic talents. He knew they needed his creative touch in designing the monument. As soon as the design was approved, something extraordinary happened. The whole night, a dedicated team of people, including medical students, hostel staff, and volunteers, worked on building a Shahid Smriti Stambha. The funding for the monument came from Pearu Sardar, who was a well-known and respected Dhaka panchayet sardar. The symbolic structure, dedicated to honouring the language martyrs, was unveiled to the public on the morning of February 24, a testament to an exceptional display of unity and support. In poignant recognition of his pivotal role in the language movement, Dr. Badrul Alam received the Ekushey Padak in 2014; he was the designer of the First Shahid Minar (Martyrs’ Monument) in 1952. This narrative unfolds as a tale of community solidarity, with the tireless efforts of diverse individuals coming together to construct an 11-foot-tall monument that stands as a lasting tribute to the language martyrs. However, the Pakistani Army and the police demolished it on February 26, 1952. In 1956, the students once again constructed the Shaheed Minar. It was inaugurated by Maulana Bhasani. But it was also disassembled afterward. Novera and Hamid’s grand design In the autumn of 1956, a pivotal meeting unfolded between Zainul Abedin, a luminary in the artistic realm, and Mr. Jabbar, the Chief Engineer of C&B, convened with the esteemed artist Hamidur Rahman and sculptor Novera Ahmed. The duo’s grand design took shape — a sprawling Shaheed Minar complex teeming with symbolism and significance. At its heart stood a semi-circular column, a poignant tribute to the eternal bond between mother and child, forever united in sacrifice. Adorning this column were symbols of watchful eyes, crafted from yellow and dark blue glass, poised to catch the sunlight and cast an ethereal glow upon the square below. The vision extended beyond mere architecture; it wove together threads of history and emotion, with every detail meticulously planned. A railing, adorned with Bangla alphabets, traced the perimetre of the seminar, while painted footprints, some stained with blood, others dark as night, marked the path of opposing forces, forever etched into the stone as a testament to the struggle for freedom. The Selection Committee, presided over by the venerable Greek architect Doxiadis, along with luminaries like Zainul Abedin and Mr. Jabbar, lent their discerning eyes to the fray. As Novera and Hamid poured their hearts into the design, they envisioned a space where memory and meaning intertwined — a sanctuary for reflection and remembrance. The government appointed Jean Delora as an architect at that time, who was in charge of keeping an eye on this work. Yet fate had other plans, and the grandeur of their vision remained but a dream, halted by the tumult of political upheaval and Ayub Khan’s martial law. Barkat’s mother inaugurated in 1963 In 1962, a committee under the direction of the vice-chancellor of Dhaka University suggested altering the original plan and speeding up the construction of the minaret. At that time, they did not even consider informing the designers about the alterations. Shaheed Barkat’s mother inaugurated it on February 21, 1963. In 1971, during the Operation Searchlight, Pakistani invaders descended upon the Shaheed Minar. They ravaged the monument. After independence, the government of Bangladesh took charge of the restoration of the Shaheed Minar. A fresh competition was announced, summoning the nation’s most esteemed artists and architects to present their visions for the revered monument. In a scene of anticipation and hope, the Central Hall of the Government House became a canvas for creativity as presentations adorned its walls. The committee, the media, and the general public all shared a mutual admiration for the design that Novera Ahmed and Hamidur Rahman’s team submitted. After that, its construction was f inished, though it failed to follow the design properly. In the mid-1980s, the Shaheed Minar underwent significant renovation again. The new design for the Shaheed Minar featured four small and one large column symbolising the mother and her fallen children on a 1,500-square-foot basis with a red sun backdrop. However, it was hastily executed, with the columns ending up shorter than planned and the main column’s head being bent more than intended. The Shaheed Minar took its present form in 1983, with marble stones used for repairs. The current Shaheed Minar stands at 14 meters (48 feet) tall. Unparallel significance of UNESCO recognition Since 1952, Bangladesh has embraced February 21st as National Martyr’s Day. On November 17, 1999, UNESCO, recognising its unparalleled significance,

Read More

The Aesthetic Affair of Ekushey Book Fair

Followed by the fragrance of the spring, February in Bangladesh is a month of turning grief into power. Hence, this month is a glowing time for the citizens, with revelries surrounded by various occasions, and Amor Ekushey (Immortal 21) Boimela (Book Fair) is one of them. Started with only 32 books on a mat under a tree in front of Bangla Academy back in 1972, the legacy of Boimela continued till date. This year (2024), too, “Amor Ekushey Book Fair” at Bangla Academy premises opened its doors for literacy and knowledge enthusiasts to commemorate the glorious history of the Bangla language movement. While it’s the love for book that might grab readers to the fair, it is the unique eye-catching design that will pull people towards the book stalls and take a look at the books. This year, Anyaprokash showcased a unique rickshaw theme stall design, featuring a square pavilion with two vault-like structures inspired by rickshaw hoods. Designed by architect SM Rahman, the pavilion features murals and Humayun Ahmed’s portrait, using steel, bamboo, and plywood for its structure. The owner of Anya Prokash Mazharul Islam previously decorated pavilion along with Humayun Ahmed celebrating Ahsan Manzil, Lalbagh Fort, Curzon Hall, the Intellectual Memorial, and this year he chose UNESCO-recognised cultural heritage rickshaw of Bangladesh as the theme. The most interesting stall design has to be Akash Prokashoni’s. At first glance, people might misconstrue it as the traditional wooden houses of Bikrampur. The owner and designer, Alamgir Sikder Loton’s love for folk culture is well-echoed in the pavilion. There are three doors on three sides of the pavilion, along with windows. Books were displayed both inside and outside the house, offering an amusing experience for the customers. The younger generation can thus become more accustomed to Bangladesh culture with such thoughtful designs. The 39th Ekushey Book Fair has 635 stalls and pavilions this year, many of which are appealingly decorated. Things that look attractive tend to draw people in. They love connecting with them, are drawn to them, and want to learn more about them. Even though books are the heart of the book fair, a brilliant mind behind the design of those book stall plays an equally significant role. Every year, the top organisation receives the Artist Qayyum Chowdhury Memorial Award for their aesthetic pavilion design. Last year, Puthiniloy bagged the very award. The book fair’s main attraction, the kid’s section, remained colourful and exciting like always. Mayurpankhi’s stall at the book fair, designed by architect and designer Reesham Shahab Tirtho, stands out with its vibrant theme and arched doors, providing a fun walk for children. Journeyman Book’s stall, designed by interior designer Nazneen Haque Mimi, is another example of simplicity and efficiency. They have arranged a free Wi-Fi zone for the visitors and also used a modern book shelf outside the stall for an artistic appeal and a comfortable visit for book lovers. Sabyasachi Hazra’s signature simple and classy design is reflected on both the pavilions, Katha Prokash and Kobi Prokashoni. The choice of colours and fonts for Katha Prokash is minimal yet catchy. The surface is covered with layers of laterite soil, which gives it an even more fun context. Whereas the white folk motifs on the complete black surface of Kobi Prokashoni attract visitors effortlessly. Bangla Prakash remained unparalleled with its wooden pavilion, which looked more like a wooden box filled with books. The modest design rather appealed as classy, and the books have been kept skilfully on book shelves, which gives off a typical bookshop vibe. The pavilion looks equally great in the evening when the pendant lights it up. This year the prize was awarded for aesthetic and artistic stalls and pavilion and publishing maximum number of books in quality. In the pavilion category, “Anyaprakash” and “Nimphia Publication” and “Bengal Books” in the stall category received the Artist Qayyum Chowdhury Smriti Award as the best organisation in aesthetic decoration among the participating publishing houses. Kathaprokash received the Chittaranjan Saha Smriti Award for publishing the highest number of quality books. In the best book category in artistic and quality judging, Prothoma Prakashan got the prize for “Bangladesh in 21st Century: Transformation of Education” written by Manzoor Ahmed, and Oitijjhya for “Jatratihas: Bangler Jatra Shilper Adi Anta” written by Moeen Ahmed and Journeyman Books got the Munir Chowdhury Smriti Award for publishing “Kilo Flight” written by Alamgir Sattar. And Roknuzzaman Khan Dadabhai Smriti Award-2024 was given to Mayurpankhi for publishing the most books for children in terms of quality. Cultural Secretary Mr. Khalil Ahmed said that efforts are being made to bring the book fair into a permanent structure. Almost every stall and pavilion of this year’s book fair was well-decorated, every stall was well-organised and many stalls had a touch of modernity. Books worth Tk 50 crore were sold in the book fair and as many as 3,751 new books had been published. Written by Fariha Hossain

Read More

Ceramics Bangladesh magazine has quality and depth of information

Since subscribing to Ceramic Bangladesh Magazine, I’ve been incredibly impressed by the quality and depth of information it provides. Ceramic Bangladesh Magazine is an essential resource for anyone involved in the Bangladeshi ceramic industry. It’s informative, and inspiring, and keeps me connected to the local ceramic community. Mr. XXX Japan

Read More

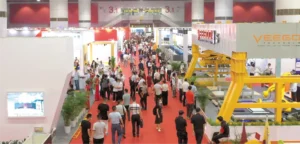

Partners – The Ornaments of The Ceramic Expo 2022

The Ceramic Expo Bangladesh-2022 was an event that brought in some 25,000 visitors and the ceramic verse under one roof. Customers and brands were connected throughout all day during the three-day-long expo, and at the end, the organising authority, Bangladesh Ceramic Manufacturers and Exporters Association (BCMEA), was overwhelmed by the tremendous response it received from the industry and the community. It was the third expo which was initiated with sponsorship support from renowned national and international brands. Locally, BCMEA was blessed with three co-sponsors for the Ceramic Expo Bangladesh 2022 – Mir Ceramic, BHL Group, and Stella Luxury Sanitaryware. Dressed in their brand colours, the sponsors decorated their pavilions with the best from their catalog, hoping to gather leads, showcase exclusives, and connect one business to another and directly with customers. BHL Ceramic Company Ltd. introduced PERLA Sanitary ware at the Ceramic Expo Bangladesh-2022 BHL Group, a conglomerate with its flagship concern BHL Ceramic Company Ltd., having four ceramic brands under its housing, was a co-sponsor of the Ceramic Expo 2022. During the event, they showcased products from four of their brands, and the front-runner was the newly introduced Sanitaryware brand, Perla Sanitaryware. The conglomerate manufactures for BHL Ceramic, KONGFU Ceramic, VINCI Ceramic, and PERLA Sanitaryware, all of which were featured at the event. With a production capacity of 33,000 sq.m/a day, expected to become 40,000-sq.m/a day manufacturer soon, the emerging brands from BHL Group have stepped into the world of ceramics, and they hope to see the subsidiaries flourish. Entering into BHL Ceramic Company Ltd. Pavilion at the expo, visitors saw the ambiance being set by a cadet grey overall backdrop. They saw their subtle blue logo above one entrance, elegantly carrying the name of the parent company. Under it reads “Driven with Integrity”. The basins from their newly introduced Perla Sanitaryware, along with commodes, and their tiles of varied sizes, were placed on walls and floor, as well as persuasively displayed to show how it would be when fitted. The front runner/star of the pavilion, the products from Perla Sanitaryware, shined throughout the event and had uniqueness in design and shape. The products from this segment are innovative, eco-friendly, extremely hygienic, and saves water. Furthermore, the company showcased its best sellers, and among its different products, there were 60×60mm High Glossy Tiles that had a shine like no other. The BHL Company Ltd. Pavilion received a special mention for one of the best pavilions decided by the jury during the awarding ceremony of the 2022 Ceramic Expo. The event went by smoothly as visitors poured in. The director of BHL Group, Mr. Sifat Arman, along with the Managing Director Mr. Shahedul Islam, graced the event with their presence. The pavilion brought in approximately 9,000-10,000 visitors in all three days providing representatives with countless leads that were later converted. Mir Ceramicof the reputable Mir Group showcased some of the bests A subsidiary of the esteemed Mir Group, Mir Ceramic is one of the largest tile manufacturers in the country, and has embarked on a mission to introduce the strongest and longest lasting tiles in the market since 2001. The company was a Co-sponsor for 2022 Expo, and decorated their pavilion with outstanding products from their catalogue. Mir Ceramic has a pool of talent with years of experience behind the manufacturing process. And with that and more, consumers have seen them turn to a ceramic leader over the past two decades. The company uses SACMI technology in its Mawna factory and sources raw materials from across the world, fine picking for every aspect of the products it manufactures. At the Ceramic Expo 2022, Mir Ceramic had a pavilion dressed in green and white. A “20 years” ceiling-high structure commemorating Mir Ceramics’ 20 years of business and achievements stood proudly at an entrance. The first few products to attract the attention were floral and checkered designs on the walls. Among the products displayed, were the SERENA, portraying dark shades of grey in matte, and DORA with its floral design, both 30×60cm in dimensions. The pavilion showcased two sizes, a rectangular shape with size 60×120cm and a square 80×80cm size, of the product REVENA which was the front runner at the pavilion alongside ALMINA. The products were beautifully showcased for the eyes of the visitors, which constituted of not only enthusiasts, but also designers, architects, and officials from real-estate companies. The Mir Ceramic pavilion won Silver for Best Pavilion of the Year and Bronze for the Most Interactive Pavilion by people’s choice during the award-giving ceremony. Thousands of visitors came in during the event, and conversations were struck. The event proceeded towards an end, and countless leads gathered. From Mir Ceramic, Mr. Anwar Hosen (Asst. Manager, Sales and Marketing), Mr. Nirmal Shah (Deputy Manager, Sales and Marketing), Mr. Mizanur Rahman (Asst. Manager, Sales and Marketing), Mr. Faisal Mahmud (Executive, Sales and Marketing), Mr. Shamshuddin Ali Ahsan (Business Development Manager), Kazi Md Abdullah Faruq (GM Sales and Marketing) and Abdulla Al Zaman (Deputy Manager, Brand) graced the event with their presence. Co-Sponsor Stella Luxury Sanitaryware introduced Italian inspired designs and more Stella Luxury Sanitaryware is a renowned brand and a trusted manufacturer of traditional and modern-day-minimalistic ceramic sanitary ware. The company ventured into the ceramic market in 2011, and ever since, has been introducing world-class products at affordable prices. The factory of the company is located in Kaligonj, Gazipur, and in partnership with SACMI, uses European technology to make their products, offering features such as water-saving, anti-scratch, soft-closing seat covers, dual flush technology, and 44 per cent stronger than local standards. The 2022 Ceramic Expo saw Stella Luxury Sanitary Ware highlight the products from the premium segment out of the catalog in their pavilion. We saw different shapes and sizes, from rectangular to oval counter basins, wash basins, high commodes, and a range of products in five light colours and two premium colours. Stella stands out when it comes to resourcefulness, as they always have replacement parts available. The market is saturated

Read More

Partners – A Historical Breakthrough in Ceramic Industry!

China’s ceramic industry has achieved a historic milestone in the goal of carbon neutrality. After nearly one year’s hard research work, the world’s first piece of ceramic tile fired with zero-carbon fuel was successfully produced in Oceano Test Center, giving a great technological support to the building ceramic industry in realising the target of Carbon Peak and Carbon Neutral. It was announced at a press conference in Foshan Xianhu Lab on December 23, 2022, the world’s first piece of ceramic tile f ired with zero-carbon pure ammonia fuel has successfully exited the Ammonia-fueled Roller Kiln at Oceano Test Center. The Associated R&D Center on Advanced Zero-carbon Combustion Technology was jointly established by Foshan Xianhu Lab, Oceano Ceramics and DLT Technology on December 27, 2021. HLT & DLT are the world’s leading suppliers of complete plant equipment for the ceramic sector. To provide turnkey project solutions to the global ceramic industry, Foshan HLT DLT Technology has been the first tunnel kiln that integrated green, low-carbon, and intelligent automation for the Chinese ceramic machinery industry to enter. Headed by Academician Mr. Cheng Yibing, a strategic scientist working at Foshan Xianhu Lab, as Chief Director of the center, the lab was aiming at the key technology of zero-carbon combustion in ceramic kilns to explore new solutions for Chinese ceramic industry. By giving full play to the advantages of the three parties in terms of production, developing and research, the center has developed the “ammonia-hydrogen fusion zero-carbon combustion technology” as well as key systems and solutions for the industrialisation. The center has developed a new series of pure ammonia type and natural gas – ammonia mixture type industrial burners with related auxiliary technologies, having realised stable ignitions in DLT industrial experiment kiln fueled with mixed ammonia and pure ammonia, showing good control of nitrogen oxides emission in compliance with the national standards. This achievement has confirmed for the first time the practical feasibility for the ceramic industry to achieve carbon peak and carbon neutral technology’s industrialisation in the future, marking an important milestone for the industry. The f iring of ceramics with zero-carbon fuel is a disruptive technical innovation, having filled up blanks of both domestic and international, showing a new energy technological path for the ceramic industry as well as for the whole of building material industry to achieve carbon peak and carbon neutral goal with great practical significance. While developing the zero-carbon combustion technology, the team also established a set of safety system and emergency management measures suitable for ammonia-fueled ceramic kilns, including operating procedures, ammonia storage, transportation and other important aspects. Based on this, the team successfully completed the update of Oceano’s ceramic roller kiln by converting the kiln from natural gas fueled mode into pure ammonia and natural gas – ammonia mixture fueled mode. Moreover, it has also developed a precision control system for liquid ammonia evaporation and supply, which is monitoring system for residual ammonia in the fume, and has jointly developed a complete set of high-efficiency liquid ammonia SCR de-nitrification system as well as other technologies and equipment. suitable for the pure ammonia combustion, an online On December 18, 2022, the kiln fueled with 100% ammonia (NH3) successfully produced glazed and unglazed tiles with continuous tile feeding and production. Tested by Oceano Research & Development Center, the quality of finished tiles is above the national standard. According to the on-site test by a third-party environmental assessment agency, the exhausted fume emission of the kiln complies to the national standard. As the first thermal equipment manufacturer to participate in the research and development of Ammonia-Hydrogen Zero-Carbon Combustion Advanced Technology, DLT has been focusing on the energy saving and emission reduction of kilns and dryers for the ceramic industry, and has been contributing greatly to the industry’s carbon consumption reduction in order to undertake its social responsibility. In future, the Associated R&D Center on Advanced Zero-carbon Combustion Technology will be further utilised in the application of mass production in the industry on the basis of the results from this pilot production, and will keep breaking through and optimising the new technology adapting with mass production, as a contribution to the ceramic industry as well as the building material industry to achieve the goal of carbon peak and carbon neutral, in order to create a disruptive technological path leading from “0” into “1” as being the first time in the world. Project Initiation: Ammonia-Hydrogen Zero-Carbon Combustion Tech When the zero carbon combustion chemical equation appeared on the screen of the launch ceremony, it marked a significant breakthrough in carbon neutrality technology. On December 28, the “Advanced Ammonia-Hydrogen Zero-Carbon Combustion Technology Demonstration Project for Ceramic Slab and Tile Mass Production Line” (“Ammonia Hydrogen Zero Carbon Combustion Project”) was officially launched at the headquarters of Monalisa Group. This is a new path explored by Monalisa in collaboration with Foshan Xianhu Laboratory, DLT, Oceano, Guangdong Anqing Technology and other companies to build ceramic zero carbon manufacturing and green development, which marks a major step forward for the industrial application of carbon-neutral technology in China’s ceramics industry, and is of great significance for accelerating the green and low-carbon transformation and development of the industry. Ammonia-hydrogen Zero-Carbon combustion technology to explore the optimal solution for the path of carbon neutrality and emission peak. With the current carbon neutrality and emission peak strategy, hydrogen energy and ammonia energy, as renewable green energy sources with high energy density, good storage and transportation convenience, clean and efficient energy, have gradually become an important part of the future energy system and are energy terminals. At present, the ammonia-hydrogen zero-carbon combustion technology has successfully completed technical tests and demonstration production in the Oceano’s experimental kiln. In order to promote the industrial application of ammonia hydrogen zero carbon combustion technology, Monalisa has joined the industrialisation research project of this technology and launched the demonstration project. Based on the developed advanced ammonia hydrogen zero carbon combustion pilot test and pollutant emission detection and control pilot test, the advanced ammonia hydrogen zero carbon

Read More

Basking in Rome’s Sun In Dhaka

Residing in a quiet corner in Dhaka’s Gulshan area, one can find a mini-Europe as soon as s/he spots Raffinato. “Raffinato Ristorante Italiano” – just by seeing the name, one can already sense its Italian essence. At the first glance, I noticed a cozy, two-story white house with an L-shaped stairway leading to a small balcony, which gave more of a European home vibe.

Read More

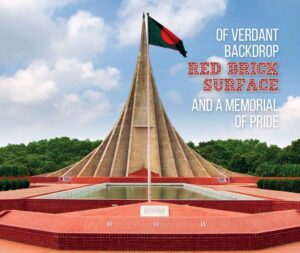

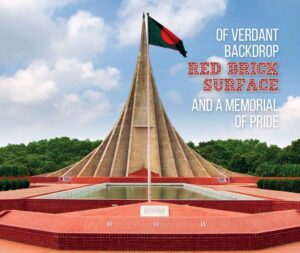

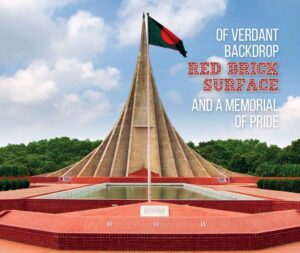

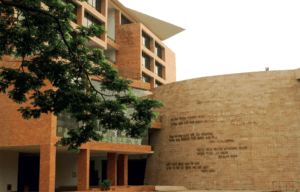

Business -Of Verdant Backdrop Red Brick Surface and A Memorial Of Pride.

Architecture, in its own language, has the power to narrate stories, forge distinctive perspectives, and evoke profound emotions. The National Martyrs’ Memorial in Savar is one of those powerful architectures that bear the history and bravery of the nation with its grandeur and glory. Located in Savar, an industrial hub on the outskirts of Dhaka, the monument stands tall as an emblem of reverence, embodying the nation’s profound gratitude to those brave souls who made the ultimate sacrifice in the pursuit of self-determination for the Bengali people. After taking a short tour around it, visitors can’t help but feel a sense of awe and pride as they contemplate the nation’s immense history and resilience. The vast landscape, the luscious greenery surrounding it, and the soaring height of the establishment will remind of its relative insignificance in the grand scheme of things. The month of March in Bangladesh is a time of remembrance and reflection. For millions of Bangladeshis, Independence Day is a day of extraordinary sentiments, containing both happiness and grief as the country earned its sovereignty 54 years ago at the cost of 3 million lives. Three phases of construction: The National Martyrs’ Memorial is designed by architect Syed Mainul Hossain (1952-2014). With a distinguished jury, including architect Muzharul Islam, a national design competition for the monument took place in 1978. (The previous attempt didn’t yield any satisfactory results.) Among 57 contenders, the young 26-year-old architect Mainul emerged victorious with his standout design. The inception of the project dates back to 1972, marking the acquisition of approximately 110 acres by the government. Of this expanse, 84 acres were dedicated to the construction of the main complex, while the remaining land was set aside for a verdant land-water greenbelt. The initial phase saw the creation of access roads, laying the foundation for subsequent development. In the second phase spanning from 1974 to 1982, significant infrastructural elements such as mass graves, helipads, parking facilities, and pavements were meticulously established. Finally, the third phase in 1982 witnessed the realisation of the main monument, along with the establishment of the greenbelt and a cafeteria, concluding the completion of this national monumental endeavour. The main monument was built by Concord in 1982 in only 89 days. In 1988, architect Syed Mainul Hossain received the Ekushey Padak, one of the highest civilian honours of the country, in recognition of his profound contribution to Bangladesh’s cultural heritage. A sneak peek into this architectural marvel: The central structure of the National Martyrs’ Memorial comprises seven pairs of triangular shapes, each representing pivotal events that propelled Bangladesh towards its independence. Starting with the outermost and shortest triangle, the structures progressively increase in height, leading up to the innermost peak. This architectural metaphor symbolises the nation’s ascent despite formidable challenges. The monument is made of concrete, in contrast with the rest of the structures and pavements, which are made of red bricks. Its design offers a multifaceted viewing experience, presenting a symmetrical pyramid-like formation when observed from afar. However, closer inspection reveals a dynamic interplay of angles and perspectives, inviting visitors to explore its intricate details firsthand. Notably, the surface of the structure is intentionally uneven, mirroring the tumultuous journey towards freedom and independence. This tactile representation serves as a poignant reminder of the sacrifices made and the resilience required to overcome adversity. The whole campus is adorned with trees, walkways, an artificial lake, and a cafeteria. Interplay of numbers: Numerology serves as a hidden vital factor behind the intricate design of the National Monument, reminiscent of ancient architectural wonders like the Athenian Parthenon, where numbers were revered as the essence of aesthetic perfection and cosmic harmony. At the heart of this establishment lies the mystical number 7, symbolising the seven pivotal movements that shaped Bangladesh’s path to independence between 1952 and 1971. The first of these 7 historical contexts is the language movement of 1952. This was followed by the United Front elections of 1954, the Constitution Movement of 1956, the Education Movement of 1962, the Six-Point Movement of 1966, the People’s Uprising of 1969, and then the final victory through the Great Liberation War of 1971. However, these 7 pillars or the number 7 also have different implications if we look at them from different facets. For example, among others, the Language Movement in 1952 contains 5+2=7; December 16, the day of independence in 1971, has 1+6=7; and there were 7 Birsreshto (war heroes) who sacrificed their lives for the cause of liberation. Written Kaniz F. Supriya

Read More

Business – Smart Fire Safety is a must for SMART BANGLADESH.

A three-day 9th International Fire Safety and Security Exhibition-2024 concluded with a focus on bolstering Bangladesh’s fire safety measures and aims to reduce fire risks, utilise modern equipment for safety, and raise awareness among the mass people. In the expo held on February 17-19, the people engaged in the industry underscored the need for amending the Bangladesh National Building Code (BNBC) 2020 as part of ensuring preventive measure of fire incidents and maintaining fire safety compliance in factories, housing and public infrastructure including mega projects. Held at the Bangabandhu International Conference Centre (BICC) in Dhaka, the expo was organised by Electronics Safety and Security Association of Bangladesh (ESSAB) in association with Bangladesh Fire Service and Civil Defence (BFSCD), Fire Fighting Equipment Business Owners Association of Bangladesh (FEBOAB), Federation of Bangladesh Chambers of Commerce and Industries (FBCCI), Bangladesh Garment Manufacturers and Exporters Association (BGMEA), Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), Bangladesh Textile Mills Association (BTMA), Dhaka North and South City Corporations, the Ministry of Commerce, and the Ministry of Home Affairs. More than 100 organisations from 30 countries including the USA, the UK, EU, China, India, the United Arab Emirates, and other Middle East countries took part in the expo. And more than 15,000 local and foreign visitors visited the expo. Salman F. Rahman, Private Industry and Investment Adviser to the Prime Minister, inaugurated the expo on February 17 while Fire Service and Civil Defence Director Brigadier General Mohammad Main Uddin, FBCCI President Mahbubul Alam and BGMEA President Faruque Hassan were present, among others. Brig. Gen. Main Uddin informed a seminar during the expo that the Fire Service and Civil Defence (FSCD) received 22,300 fire incidents per year but last year it was increased to 28,703 while on an average 150 deaths are recorded every year. In these incidents, an average loss was Tk 368 crore each year and the loss amounted to around Tk 793 crore last year. About 36 per cent fire incidents was caused by electricity last year, he added. Architect Iqbal Habib said using technology harnessing data from every level is a must to monitor and manage city infrastructure to build smart city and provide facilities to citizens. He also said if the soft copy of the building design is on the device, it will reach the fire fighters at the premises within a second. The PPP model will ensure smart safety and security solution to make sure that fire incident would not take place. Investment required for boosting the industry: With the expansion of industrialisation, the demand for fire safety and security equipment is rapidly growing in Bangladesh. But the country is still highly dependent on imported products. Industry insiders say Bangladesh has to depend on around 95 per cent import of the products. So, the country has a scope of attracting a huge investment, and also export the products meeting domestic demand for around Tk 15,000 crore market, if investors get adequate policy support from the government. ESSAB Safety Excellence Award 2024: A total of 13 organisations have been awarded at the expo for ensuring building code compliance and fire safety measures in residential, industrial, commercial buildings. Among them, Rancon Artisti Residences stood first in the residential building category, while Sheltech Rubynur stood second, and Concord Shapla third. In the Commercial Building Category, Shanta Forum, Concord MK Heritage and BGMEA Complex received the award as the First, Runner-Up and Second Runner-Up. Six companies jointly won the excellence award in the Industrial (RMG) category. Among them, Glamour Dresses Ltd. and Designtex Knitwear Ltd. were named the top winners. Tasniah Fabrics Ltd. and SQ Birichina Ltd. came next, followed by Sterling Denims Ltd. and Silken Sewing Ltd. Besides, BM Container Depot Ltd. received the award in the industrial other category. ESSAB also gave special recognition to five fire service personnel for their brave role in fire fighting and rescue operations. They are Deputy Assistant Director of Fire Service and Civil Defence Department Md. Faisalur Rahman and Mohammad Safiqul Islam, Senior Station Officer Md. Nazim Uddin Sarkar, Warehouse Inspector Md. Zahirul Islam and Fire Fighter Alhaj Miah. PPP required to explore untapped market: ESSAB: The ESSAB Secretary General, Zakir Uddin Ahmed, said the sector is important to protect people’s lives and properties from fire and earthquake incidents, and ensure sustainable economic development. So, what are needed include significant awareness, regular checks of the fire safety equipment, and use of quality materials. Mr. Zakir, also Chief Executive Officer of ZM International, stated that PPP is required to explore the untapped market. “We are ready to help investors here. So, policy assistance is the main issue to bring more investment. To create awareness, he fires safety issue should be included in textbooks,” he said adding that high import duty on the products is a key challenge in the industry. In this context, the government should provide all necessary facilities such as policy support, duty cut, and incentive so that investors come to invest in the sector.

Read More

Business – A Glimpse of Timeless Elegance in the British-Pub Revival named BAGHA Club

Located in the Gulshan, Dhaka, the newly renovated bar of The British Aid Guest House Association (BAGHA) Club is a renovation project designed by Zero Inch Interiors Ltd. The British-Pub-inspired interior design of the BAGHA Club’s bar is conceptualised to transform the space into a comfortable and cozy space. The guiding vision for the interior design of the bar has aimed to offer club members a sanctuary – a place where they could briefly detach from their demanding routines, relax, and recharge in a welcoming atmosphere following a day of work. The British Aid Guest House Association (BAGHA) Club was established in 1979. It is a part of the British High Commission estate and proudly serves a wonderfully diverse mix of European Union nationals. Among various amenities that the club offers, including a tennis court, children’s play area, all-day restaurants, swimming pools, and a library, the bar stands out as a focal point of social interaction and relaxation. Recently undergoing a remarkable renovation by the design team of Zero Inch Interiors Ltd., the British-Pub-inspired interior now exudes a timeless charm that seamlessly blends the traditional British pub environment with modern aesthetics. The Concept Behind the Renovation Project The interior embodies a distinctive British Pub aesthetic, interpreting traditional British elements in a contemporary style. Sharing the concept of the BAGHA club, Architect Ariful Islam says, “The idea was to renovate the bar in resemblance to British pubs, while, at the same time, doing it with minimal intervention to make the space inviting, cozy, and long-lasting.” A wall was dismantled, which, in fact, made the most visible change and expanded the space. This step in design resulted in lightening up the atmosphere of the club. After rethinking the space, the modified open-plan layout ensured that the bar counter was transformed into a rectangular shape, making it interactive and interesting. The renovation overall, therefore, achieves a delicate balance between reflecting the charm of British pubs and infusing a modern, vibrant dynamism into the space. Challenges in the Interior Design Designed by architect Muhammad Ariful Islam and his team in a remarkably brief two-month timeframe, this 2800-square-foot contemporary renovation stands as a one-of-a-kind endeavour in Bangladesh. “We’re confined to some challenges as the site was a rental space, which dictated that major demolitions were not permissible here,” added the architect. The primary challenges faced by the design team during the construction phase of the bar interior design were centred around the principles of minimal design intervention, budget constraints, and the necessity to execute the design within a notably short timeframe. Balancing all these constraints required careful consideration and strategic decision-making to ensure the success and execution of the envisioned space. Color Palette and Materiality In this interior project, wood has been selected as the primary construction material, complemented by glass and metal details. The utilisation of wooden panels, intricate carvings, and carefully curated lighting collectively contribute to creating a cozy, warm, and inviting ambiance. Furthermore, the extensive collection of bar accessories enhances the overall visual appeal, adding a layer of sophistication to the space. A new bar counter along with bar stools have been incorporated into the bar interior design, and this rendition perfectly completes the bar. The stunning stools with red-wine upholstery add a dash of colour to the interior and complement the wooden tone. Lastly, the sophisticated chandeliers add a dramatic charm to the entire British Pub ambiance. Architect Ariful Islam explains, “We preferred Challenges in the Interior Design Designed by architect Muhammad Ariful Islam and his team in a remarkably brief two-month timeframe, this 2800-square-foot contemporary renovation stands as a one-of-a-kind endeavour in Bangladesh. “We’re confined to some challenges as the site was a rental space, which dictated that major demolitions were not permissible here,” added the architect. The primary challenges faced by the design team during the construction phase of the bar interior design were centred around the principles of minimal design intervention, budget constraints, and the necessity to execute the design within a notably short timeframe. Balancing all these constraints required careful consideration and strategic decision-making to ensure the success and execution of the envisioned space. Color Palette and Materiality In this interior project, wood has been selected as the primary construction material, complemented by glass and metal details. The utilisation of wooden panels, intricate carvings, and carefully curated lighting collectively contribute to creating a cozy, warm, and inviting ambiance. Furthermore, the extensive collection of bar accessories enhances the overall visual appeal, adding a layer of sophistication to the space. A new bar counter along with bar stools have been incorporated into the bar interior design, and this rendition perfectly completes the bar. The stunning stools with red-wine upholstery add a dash of colour to the interior and complement the wooden tone. Lastly, the sophisticated chandeliers add a dramatic charm to the entire British Pub ambiance. to choose wood as the primary material because when warm light falls on wood, it creates a golden effect. The red hues further enhance the vibrancy and liveliness of the space.” The ceiling is kept simple and devoid of (intricate) details, maintaining a blackout effect. The flooring features darker tones with rustic tiles adorned with wooden patterns. This careful selection of materials and design elements contributes to the overall coherence and elegance of the bar’s interior. Zero Waste Design Philosophy One mentionable feature of this renovation is the Zero Waste Design Philosophy of the design team. In adherence to this design philosophy, they embraced creative methods to repurpose furniture in the design of this bar. Through a commitment to sustainability, repurposed and recycled furniture, along with other items, were integrated into the overall design. Each furniture piece underwent resizing and repainting to align with current functional needs. Another key aspect of the sustainability initiative involved the replacement of all damaged glass windows, which were previously allowing rainwater to infiltrate the interior. By incorporating new, weather-resistant windows, they not only addressed the structural issues but also contributed to the energy efficiency of the

Read More

Spotlight Of Verdant Backdrop Red Brick Surface and A Memorial Of Pride

Architecture, in its own language, has the power to narrate stories, forge distinctive perspectives, and evoke profound emotions. The National Martyrs’ Memorial in Savar is one of those powerful architectures that bear the history and bravery of the nation with its grandeur and glory. Located in Savar, an industrial hub on the outskirts of Dhaka, the monument stands tall as an emblem of reverence, embodying the nation’s profound gratitude to those brave souls who made the ultimate sacrifice in the pursuit of self-determination for the Bengali people. After taking a short tour around it, visitors can’t help but feel a sense of awe and pride as they contemplate the nation’s immense history and resilience. The vast landscape, the luscious greenery surrounding it, and the soaring height of the establishment will remind of its relative insignificance in the grand scheme of things. The month of March in Bangladesh is a time of remembrance and reflection. For millions of Bangladeshis, Independence Day is a day of extraordinary sentiments, containing both happiness and grief as the country earned its sovereignty 54 years ago at the cost of 3 million lives. Three phases of construction: The National Martyrs’ Memorial is designed by architect Syed Mainul Hossain (1952-2014). With a distinguished jury, including architect Muzharul Islam, a national design competition for the monument took place in 1978. (The previous attempt didn’t yield any satisfactory results.) Among 57 contenders, the young 26-year-old architect Mainul emerged victorious with his standout design. The inception of the project dates back to 1972, marking the acquisition of approximately 110 acres by the government. Of this expanse, 84 acres were dedicated to the construction of the main complex, while the remaining land was set aside for a verdant land-water greenbelt. The initial phase saw the creation of access roads, laying the foundation for subsequent development. In the second phase spanning from 1974 to 1982, significant infrastructural elements such as mass graves, helipads, parking facilities, and pavements were meticulously established. Finally, the third phase in 1982 witnessed the realisation of the main monument, along with the establishment of the greenbelt and a cafeteria, concluding the completion of this national monumental endeavour. The main monument was built by Concord in 1982 in only 89 days. In 1988, architect Syed Mainul Hossain received the Ekushey Padak, one of the highest civilian honours of the country, in recognition of his profound contribution to Bangladesh’s cultural heritage. A sneak peek into this architectural marvel: The central structure of the National Martyrs’ Memorial comprises seven pairs of triangular shapes, each representing pivotal events that propelled Bangladesh towards its independence. Starting with the outermost and shortest triangle, the structures progressively increase in height, leading up to the innermost peak. This architectural metaphor symbolises the nation’s ascent despite formidable challenges. The monument is made of concrete, in contrast with the rest of the structures and pavements, which are made of red bricks. Its design offers a multifaceted viewing experience, presenting a symmetrical pyramid-like formation when observed from afar. However, closer inspection reveals a dynamic interplay of angles and perspectives, inviting visitors to explore its intricate details firsthand. Notably, the surface of the structure is intentionally uneven, mirroring the tumultuous journey towards freedom and independence. This tactile representation serves as a poignant reminder of the sacrifices made and the resilience required to overcome adversity. The whole campus is adorned with trees, walkways, an artificial lake, and a cafeteria. Interplay of numbers: Numerology serves as a hidden vital factor behind the intricate design of the National Monument, reminiscent of ancient architectural wonders like the Athenian Parthenon, where numbers were revered as the essence of aesthetic perfection and cosmic harmony. At the heart of this establishment lies the mystical number 7, symbolising the seven pivotal movements that shaped Bangladesh’s path to independence between 1952 and 1971. The first of these 7 historical contexts is the language movement of 1952. This was followed by the United Front elections of 1954, the Constitution Movement of 1956, the Education Movement of 1962, the Six-Point Movement of 1966, the People’s Uprising of 1969, and then the final victory through the Great Liberation War of 1971. However, these 7 pillars or the number 7 also have different implications if we look at them from different facets. For example, among others, the Language Movement in 1952 contains 5+2=7; December 16, the day of independence in 1971, has 1+6=7; and there were 7 Birsreshto (war heroes) who sacrificed their lives for the cause of liberation. Written Kaniz F. Supriya

Read More

Spotlight Smart Fire Safety is a must for SMART BANGLADESH

A three-day 9th International Fire Safety and Security Exhibition-2024 concluded with a focus on bolstering Bangladesh’s fire safety measures and aims to reduce fire risks, utilise modern equipment for safety, and raise awareness among the mass people. In the expo held on February 17-19, the people engaged in the industry underscored the need for amending the Bangladesh National Building Code (BNBC) 2020 as part of ensuring preventive measure of fire incidents and maintaining fire safety compliance in factories, housing and public infrastructure including mega projects. Held at the Bangabandhu International Conference Centre (BICC) in Dhaka, the expo was organised by Electronics Safety and Security Association of Bangladesh (ESSAB) in association with Bangladesh Fire Service and Civil Defence (BFSCD), Fire Fighting Equipment Business Owners Association of Bangladesh (FEBOAB), Federation of Bangladesh Chambers of Commerce and Industries (FBCCI), Bangladesh Garment Manufacturers and Exporters Association (BGMEA), Bangladesh Knitwear Manufacturers and Exporters Association (BKMEA), Bangladesh Textile Mills Association (BTMA), Dhaka North and South City Corporations, the Ministry of Commerce, and the Ministry of Home Affairs. More than 100 organisations from 30 countries including the USA, the UK, EU, China, India, the United Arab Emirates, and other Middle East countries took part in the expo. And more than 15,000 local and foreign visitors visited the expo. Salman F. Rahman, Private Industry and Investment Adviser to the Prime Minister, inaugurated the expo on February 17 while Fire Service and Civil Defence Director Brigadier General Mohammad Main Uddin, FBCCI President Mahbubul Alam and BGMEA President Faruque Hassan were present, among others. Brig. Gen. Main Uddin informed a seminar during the expo that the Fire Service and Civil Defence (FSCD) received 22,300 fire incidents per year but last year it was increased to 28,703 while on an average 150 deaths are recorded every year. In these incidents, an average loss was Tk 368 crore each year and the loss amounted to around Tk 793 crore last year. About 36 per cent fire incidents was caused by electricity last year, he added. Architect Iqbal Habib said using technology harnessing data from every level is a must to monitor and manage city infrastructure to build smart city and provide facilities to citizens. He also said if the soft copy of the building design is on the device, it will reach the fire fighters at the premises within a second. The PPP model will ensure smart safety and security solution to make sure that fire incident would not take place. Investment required for boosting the industry: With the expansion of industrialisation, the demand for fire safety and security equipment is rapidly growing in Bangladesh. But the country is still highly dependent on imported products. Industry insiders say Bangladesh has to depend on around 95 per cent import of the products. So, the country has a scope of attracting a huge investment, and also export the products meeting domestic demand for around Tk 15,000 crore market, if investors get adequate policy support from the government. ESSAB Safety Excellence Award 2024: A total of 13 organisations have been awarded at the expo for ensuring building code compliance and fire safety measures in residential, industrial, commercial buildings. Among them, Rancon Artisti Residences stood first in the residential building category, while Sheltech Rubynur stood second, and Concord Shapla third. In the Commercial Building Category, Shanta Forum, Concord MK Heritage and BGMEA Complex received the award as the First, Runner-Up and Second Runner-Up. Six companies jointly won the excellence award in the Industrial (RMG) category. Among them, Glamour Dresses Ltd. and Designtex Knitwear Ltd. were named the top winners. Tasniah Fabrics Ltd. and SQ Birichina Ltd. came next, followed by Sterling Denims Ltd. and Silken Sewing Ltd. Besides, BM Container Depot Ltd. received the award in the industrial other category. ESSAB also gave special recognition to five fire service personnel for their brave role in fire fighting and rescue operations. They are Deputy Assistant Director of Fire Service and Civil Defence Department Md. Faisalur Rahman and Mohammad Safiqul Islam, Senior Station Officer Md. Nazim Uddin Sarkar, Warehouse Inspector Md. Zahirul Islam and Fire Fighter Alhaj Miah. PPP required to explore untapped market: ESSAB: The ESSAB Secretary General, Zakir Uddin Ahmed, said the sector is important to protect people’s lives and properties from fire and earthquake incidents, and ensure sustainable economic development. So, what are needed include significant awareness, regular checks of the fire safety equipment, and use of quality materials. Mr. Zakir, also Chief Executive Officer of ZM International, stated that PPP is required to explore the untapped market. “We are ready to help investors here. So, policy assistance is the main issue to bring more investment. To create awareness, he fires safety issue should be included in textbooks,” he said adding that high import duty on the products is a key challenge in the industry. In this context, the government should provide all necessary facilities such as policy support, duty cut, and incentive so that investors come to invest in the sector.

Read More

A Glimpse of Timeless Elegance in the British-Pub Revival named BAGHA Club

Located in the Gulshan, Dhaka, the newly renovated bar of The British Aid Guest House Association (BAGHA) Club is a renovation project designed by Zero Inch Interiors Ltd. The British-Pub-inspired interior design of the BAGHA Club’s bar is conceptualised to transform the space into a comfortable and cozy space. The guiding vision for the interior design of the bar has aimed to offer club members a sanctuary – a place where they could briefly detach from their demanding routines, relax, and recharge in a welcoming atmosphere following a day of work. The British Aid Guest House Association (BAGHA) Club was established in 1979. It is a part of the British High Commission estate and proudly serves a wonderfully diverse mix of European Union nationals. Among various amenities that the club offers, including a tennis court, children’s play area, all-day restaurants, swimming pools, and a library, the bar stands out as a focal point of social interaction and relaxation. Recently undergoing a remarkable renovation by the design team of Zero Inch Interiors Ltd., the British-Pub-inspired interior now exudes a timeless charm that seamlessly blends the traditional British pub environment with modern aesthetics. The Concept Behind the Renovation Project The interior embodies a distinctive British Pub aesthetic, interpreting traditional British elements in a contemporary style. Sharing the concept of the BAGHA club, Architect Ariful Islam says, “The idea was to renovate the bar in resemblance to British pubs, while, at the same time, doing it with minimal intervention to make the space inviting, cozy, and long-lasting.” A wall was dismantled, which, in fact, made the most visible change and expanded the space. This step in design resulted in lightening up the atmosphere of the club. After rethinking the space, the modified open-plan layout ensured that the bar counter was transformed into a rectangular shape, making it interactive and interesting. The renovation overall, therefore, achieves a delicate balance between reflecting the charm of British pubs and infusing a modern, vibrant dynamism into the space. Challenges in the Interior Design Designed by architect Muhammad Ariful Islam and his team in a remarkably brief two-month timeframe, this 2800-square-foot contemporary renovation stands as a one-of-a-kind endeavour in Bangladesh. “We’re confined to some challenges as the site was a rental space, which dictated that major demolitions were not permissible here,” added the architect. The primary challenges faced by the design team during the construction phase of the bar interior design were centred around the principles of minimal design intervention, budget constraints, and the necessity to execute the design within a notably short timeframe. Balancing all these constraints required careful consideration and strategic decision-making to ensure the success and execution of the envisioned space. Color Palette and Materiality In this interior project, wood has been selected as the primary construction material, complemented by glass and metal details. The utilisation of wooden panels, intricate carvings, and carefully curated lighting collectively contribute to creating a cozy, warm, and inviting ambiance. Furthermore, the extensive collection of bar accessories enhances the overall visual appeal, adding a layer of sophistication to the space. A new bar counter along with bar stools have been incorporated into the bar interior design, and this rendition perfectly completes the bar. The stunning stools with red-wine upholstery add a dash of colour to the interior and complement the wooden tone. Lastly, the sophisticated chandeliers add a dramatic charm to the entire British Pub ambiance. Architect Ariful Islam explains, “We preferred Challenges in the Interior Design Designed by architect Muhammad Ariful Islam and his team in a remarkably brief two-month timeframe, this 2800-square-foot contemporary renovation stands as a one-of-a-kind endeavour in Bangladesh. “We’re confined to some challenges as the site was a rental space, which dictated that major demolitions were not permissible here,” added the architect. The primary challenges faced by the design team during the construction phase of the bar interior design were centred around the principles of minimal design intervention, budget constraints, and the necessity to execute the design within a notably short timeframe. Balancing all these constraints required careful consideration and strategic decision-making to ensure the success and execution of the envisioned space. Color Palette and Materiality In this interior project, wood has been selected as the primary construction material, complemented by glass and metal details. The utilisation of wooden panels, intricate carvings, and carefully curated lighting collectively contribute to creating a cozy, warm, and inviting ambiance. Furthermore, the extensive collection of bar accessories enhances the overall visual appeal, adding a layer of sophistication to the space. A new bar counter along with bar stools have been incorporated into the bar interior design, and this rendition perfectly completes the bar. The stunning stools with red-wine upholstery add a dash of colour to the interior and complement the wooden tone. Lastly, the sophisticated chandeliers add a dramatic charm to the entire British Pub ambiance. to choose wood as the primary material because when warm light falls on wood, it creates a golden effect. The red hues further enhance the vibrancy and liveliness of the space.” The ceiling is kept simple and devoid of (intricate) details, maintaining a blackout effect. The flooring features darker tones with rustic tiles adorned with wooden patterns. This careful selection of materials and design elements contributes to the overall coherence and elegance of the bar’s interior. Zero Waste Design Philosophy One mentionable feature of this renovation is the Zero Waste Design Philosophy of the design team. In adherence to this design philosophy, they embraced creative methods to repurpose furniture in the design of this bar. Through a commitment to sustainability, repurposed and recycled furniture, along with other items, were integrated into the overall design. Each furniture piece underwent resizing and repainting to align with current functional needs. Another key aspect of the sustainability initiative involved the replacement of all damaged glass windows, which were previously allowing rainwater to infiltrate the interior. By incorporating new, weather-resistant windows, they not only addressed the structural issues but also contributed to the energy efficiency of the

Read More

Spotlight Artisan Ceramics at the forefront (04)

Amongst the Royal collection in the Buckingham Palace resides gold-covered renditions of Artisan Ceramics. From a company struggling to export, to winning the national export trophy five times in a row, Artisan Ceramics has seen 3 times expansion over the past few years. The entirety of a company’s growth and success inevitably relies on the decisions made internally. Artisan Ceramics Ltd. suffered significant loss until 2011. With new leadership under Finlays, and a change in the modality of business and redesigning, it now has a factory constructed across six acres of land in Sreepur, Gazipur, and a capacity of producing 10 million pieces of assorted premium quality porcelain tableware annually. The current expansion will raise this capacity to 22 million. Artisan Ceramics is an export-oriented tableware company that supplies to over 20 countries across Europe, America, and Asia, and has evolved into a leading manufacturer with no stop to its growth. The company has a contribution of 12-15 percent in the national export revenue. Surely, success in such a short time is a wonder on its own. To find out more, Ceramic Bangladesh Magazine author recently had the opportunity to discuss the adaptations of Artisan Ceramics that led to its success, with M. Mamunur Rashid, CEO of Artisan Ceramics Ltd. Here’s what we’ve learned: The first adaptation Artisan knew Saggar firing was wasteful Saggar or Saguaro is a covering used over ceramic ware when under intensive firing in the kilns. This protection helps safeguard the ware from coming in direct contact with the Kiln, debris inside the kiln, and other gases and smoke. The problem with saggar firing is that the saggar heats up first and then transfers the heat to the product; this makes the process 15-hour long cycle. With Artisan’s adaptation, open and fast firing, it’s a six-hour firing process. “Time-wise and price-wise, Saggar is inefficient. Again, there is the cost of the man behind the machine,” says Mr. Rashid. Fired three times for a longer life! “I have traveled across more than 10 countries just to see the technology companies have adopted, and learned, that the type of products we tend to manufacture are widely unavailable,” said Mr. Rashid. “We have products that have been fired three times, which make them much more durable. These products are more popular in Europe since they are more durable and can withstand knives and forks,” he added. At Artisan, products are fired at high degrees of temperatures — 1330°C to 1350°C, about 100° higher than the global rivals. Discussing global demand with relevance to this particular firing process, we find: “The hard glaze we are using, makes the product stronger, more scratch-proof, and absorption free,” said Mr. Rashid. The global demand has shifted towards such products because of such features. Raw materials sourced from around the world Artisan Ceramics sources its raw materials from almost every corner of the globe –the UK, Germany, Italy, New Zealand, Vietnam, Japan, China, and India are some of them. The two types of minerals that make up for 50% of the body, feldspar, and quartz, are brought in from Rajasthan, India. The company also imports alumina which is used to make the body stronger and helps meet HoReCa standards. “Using the best quality raw material with a natural colour is important because the glaze is translucent and the body colour is what you see,” he said. These designs are in trend now and a personal favourite of Mr. Rashid. The company even imports from specific mines. Furthermore, Artisan buys the best quality gold from Heraeus Germany and colors from Izawa Pigments, Japan. Innovative Designs that go well with the trend, and the technology behind it. Artisan is constantly working on new designs. “We are innovating and have recently created double-layer body tea cup that keeps tea & coffee warm for a longer period of time,” Mr. Rashid mentioned. The design depends on customer trends and comes in cyclic order, says Mr. Rashid. Something that is currently trending are reactive glazes where you allow the finishing to be exactly how the kilns are making them fascinate many people. “Keeping up with the ever-evolving trends is a constant challenge, but traditional designs have resurfaced and are a popular preference now,” said Mr. Rashid. Artisan will be introducing a certain collection inspired by the Rajasthani culture. A designer from Sri Lanka by the name of Sudath Fernando is also coming in to train employees. Stay tuned with us for future features. Regarding technology, he said: “We want to make our factory fuel efficient. Our dryers are like ovens that collect heat and reuse it. I have visited a few factories in Europe and have seen how they are doing things, we have called SACMI, Italy, to help us upgrade.” The machines at Artisan’s factory are from the USA, the UK, Japan, Taiwan, and China. Artisan has taken green initiatives- they refine and reuse 90% of wastewater, collect rainwater in underground tanks, and reuse heat from the ovens. The company purifies water to the extent that it can be used for irrigation. “Every factory is concerned and the government is putting emphasis on sustainable approaches,” stated Mr. Rashid. Artisan’s plan to sell in bulk Following the recent expansion, Artisan is now concentrating on bulk buyers- examples would be hypermarkets. The marketing team is also trying to bring about a trend change by promoting the use of porcelain over bone china. This is because the water absorption of Bone China is high, it loses colour, and porcelain survives longer. Ultra Bone Porcelain: the newest innovation from Artisan Some customers are price-centric and some look for quality. That is why Artisan needed to innovate a new product retaining the same mechanical strength of pure porcelain and exceptional whiteness that was sure to win people over. Henceforth, came the Ultra Bone Porcelain. Mr. Rashid introduced a special body that can beat the competition and customers are willing to pay premium price for it. Artisan performs CSR Artisan gives education

Read More

Artisan Ceramics at the forefront